| |

Bioremediation Field

|

United States Environmental Protection Agency

Office of Research and Development, Washington, DC 20460

Office of Solid Waste and Emergency Response, Washington, DC 20460

EPA/540/F-95/506H September 1995

| |

Bioremediation Field

|

Location: St. Louis Park, Minnesota

Laboratories/Agencies: U.S. EPA National Risk Management and Research

Laboratory (NRMRL), Superfund Innovative Technology Evaluation (SITE) Program,

U.S. EPA Region 5, Minnesota Pollution Control Agency

Media and Contaminants: Polycyclic aromatic hydrocarbons (PAHs) in

soil

Treatment: Bioventing

Date of Initiative Selection: October 1992

Objective: To evaluate the effectiveness of bioventing PAH-contaminated

soil

Bioremediation Field Initiative Contacts: Paul McCauley and Richard

Brenner, U.S. EPA NRMRL, 26 West Martin Luther King Drive, Cincinnati, OH

45268

Regional Contact: Daryl Owens, U.S. EPA Region 5, Waste Management

Division, 77 West Jackson Boulevard, Chicago, IL 60604

This Bioremediation Field Initiative project is under way in St. Louis Park, Minnesota, at the former site of Reilly Tar and Chemical Corporation’s coal tar distillation and wood preserving plant. From 1917 to 1972, wastewater discharges and dumping from this plant contaminated about 80 acres of soil and the underlying ground water with wood preserving wastes. In 1978, the Minnesota Department of Health discovered significant concentrations of polycyclic aromatic hydrocarbons (PAHs) in six municipal drinking water wells neighboring the Reilly Tar plant. St. Louis Park currently is pumping and treating the contaminated ground water plume, but without an effort to control the source of PAHs, pumping and treating might be necessary for several hundred years.

This Initiative project is evaluating bioventing of PAH-contaminated soil through the U.S. EPA Superfund Innovative Technology Evaluation (SITE) Program and the U.S. EPA National Risk Management Research Laboratory’s (NRMRL) Biosystems Program. Bioventing has proven effective at remediating lightweight petroleum distillates such as JP-4 jet fuel; this is the first evaluation of bioventing’s effectiveness for remediation of larger molecular weight hydrocarbons.

The SITE program conducted a preliminary site characterization, including soil sampling, soil gas monitoring, and in situ respiration testing, in August 1992. Soil sampling revealed PAH contamination in sandy vadose soil ranging from 3 to 10 ft below the surface. Soil gas monitoring and respiration tests indicated that the soil’s aerobic microbial activity and air permeability are high enough for successful bioventing.

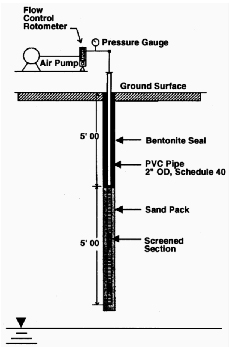

In November 1992, baseline soil sampling was conducted and a full-scale bioventing system installed on a 50-ft by 50-ft plot (see Figure 1). A control plot of equal size and contaminant levels also was established to gauge the effectiveness of the bioventing system. The system consists of one air injection well with screening 5 to 10 ft below ground level (see Figure 2), a 2.5-hp blower, a network of 54 soil gas sampling probes, and a system to monitor soil temperature and ground-water elevation. The blower and vent well deliver 100 ft³ of air per hour to the contaminated soil.

Figure 1. Layout of bioventing installation on experimental plot.

Figure 2. Schematic of air injection vent well.

Personnel from the City of St. Louis Park inspect the site for malfunctions every 2 weeks. In situ respiration tests are being conducted four times per year by NRMRL. At the completion of the project, final soil samples will be collected from the experimental and the control plots.

Quarterly shut-down respiration tests over the first 2 years have ranged from below detection to 0.48 percent O2/hr. The highest respiration rates were found in the western half of the treatment area where PAH contamination was also the heaviest.

Current average measured respiration rates are consistent with a 14 percent reduction in PAH contamination per year. After 2 years bioventing, 70 soil borings were taken from a 25-ft x 25-ft section in the northwest corner of the test plot. PAH analysis of these soil borings was statistically inconclusive.

The demonstration project is expected to last 3 years, at which point it is estimated that soil core samples must show at least a 27 percent reduction in PAH levels to be statistically significant. If bioventing successfully biodegrades PAHs at this rate, complete bioremediation of the site would take 10 to 15 years if large-scale bioventing is undertaken. The results of this study will help deter-mine whether bioventing can be considered at Superfund sites as a cost-effective treatment for remediating PAH-contaminated soils.

| The Bioremediation Field Initiative was established in 1990 to expand the nation’s field experience in bioremediation technologies. The Initiative’s objectives are to more fully document the performance of full-scale applications of bioremediation; provide technical assistance to regional and state site managers; and provide information on treatability studies, design, and operation of bioremediation projects. The Initiative currently is performing field evaluations of bioremediation at eight other hazardous waste sites: Libby Ground Water Superfund site, Libby, MT; Park City Pipeline, Park City, KS; Bendix Corporation/Allied Automotive Superfund site, St. Joseph, MI; West KL Avenue Landfill Superfund site, Kalamazoo, MI; Eielson Air Force Base Superfund site, Fairbanks, AK; Hill Air Force Base Superfund site, Salt Lake City, UT; Reilly Tar and Chemical Corporation Superfund site, St. Louis Park, MN; and Public Service Company, Denver, CO. To obtain profiles on these additional sites or to be added to the Initiative’s mailing list, call 513-569-7562. For further information on the Bioremediation Field Initiative, contact Fran Kremer, Coordinator, Bioremediation Field Initiative, U.S. EPA, Office of Research and Development, 26 West Martin Luther King Drive, Cincinnati, OH 45268; or Michael Forlini, U.S. EPA, Technology Innovation Office, Office of Solid Waste and Emergency Response, 401 M Street, SW., Washington, DC 20460. |