|

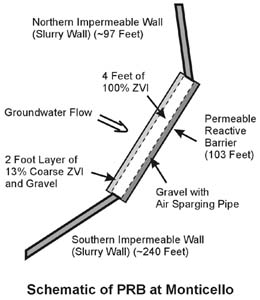

Ground Water Currents, June 2000, Issue No. 36ContentsMonticello Permeable Reactive Barrier Project Field Evaluation of Solvent Extraction Residual Biotreatment (SERB) Subsurface Biofilm Barriers Contaminated Ground Water Containment Monticello Permeable Reactive Barrier Projectby Clay Carpenter, MACTEC–ERS Inc.; Stan Morrison, Roy F. Weston, Inc.; and Don Metzler, U.S. Department of Energy, Grand Junction Project Office A permeable reactive barrier (PRB) system, using zero-valent iron (ZVI), is cleaning up metal-contaminated ground water at a former uranium and vanadium ore-processing mill at Monticello, Utah. The U.S. Department of Energy (DOE) Grand Junction Project Office (GJPO) is managing the cleanup in cooperation with EPA Region 8 and the State of Utah. The site is regulated under the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), and the project is being funded by the DOE Office of Science and Technology Accelerated Site Technology Deployment Program. Uranium, selenium, vanadium, manganese, and arsenic are the major contaminants of concern in ground water at the site. Following an Interim Record of Decision calling for emplacement of a PRB hydraulically downgradient of the site, both laboratory and field treatability studies were used to guide design of the PRB and selection of the most appropriate reactive materials. PRB Construction The remediation system includes a PRB and impermeable funnel walls (see Figure below). The barrier was built by driving steel sheet piling into the bedrock forming a rectangular box approximately 100 feet long by 8 feet wide. The native soils inside the box were replaced with –8/+20 mesh ZVI and gravel packs upgradient and downgradient of the ZVI. The ZVI and gravel packs extend more than 1 foot into the underlying bedrock aquiclude. The upgradient gravel pack is approximately 2 feet wide and is composed of 13 percent-4/20 mesh ZVI (by volume) mixed uniformly with 0.5-inch gravel. The middle section of the PRB contains 4 feet of 100 percent-ZVI. The downstream gravel pack is approximately 2 feet wide composed of 0.5-inch gravel and includes an air-sparging system constructed of perforated polyvinyl-chloride pipe. The air sparging system will be used to remove dissolved manganese and iron if the concentrations increase to unacceptable levels. The south impermeable wall is 240 feet in length and the north wall is 97 feet in length; the impermeable walls are composed of a bentonite and soil slurry mix. The impermeable walls funnel contaminated ground water to the PRB for treatment. Construction was completed on June 30, 1999.

Monitoring Results In the summer of 1999, a monitoring network of approximately 50 wells was established centered on the reactive portion of the PRB. Ground-water-quality samples and water-level data were taken in September, October, and November 1999, and in January 2000. Results indicated that initial concentrations of uranium (700 µg/L), vanadium (400 µg/L), selenium (40 µg/L), and arsenic (10 µg/L) have been reduced to non-detectable levels as ground water exits the PRB. Concentrations of manganese, a trace contaminant in ZVI, increase slightly across the PRB, but these concentrations are expected to decrease over time. Iron concentrations exiting the reactive wall were much lower than expected. Upcoming Activities A tracer study will be conducted to better evaluate the hydraulic performance of the reactive gate. In addition, a colloidal borescope will be used to measure the rate and direction of ground-water flow in and adjacent to the PRB. Sampling and analysis of the ground water will continue on a quarterly basis. For more information, contact Don Metzler (DOE/GJPO) at 970-248-7612 or E-mail dmetzler@doegjpo.com. Field Evaluation of Solvent Extraction Residual Biotreatment (SERB)by Guy W. Sewell, Susan C. Mravik, and A. Lynn Wood, U.S. Environmental Protection Agency, National Risk Management Research Laboratory Laboratory and pilot-scale experiments have demonstrated the potential of cosolvent-enhanced in situ extraction to remove DNAPL in porous media. While this method is effective for mass removal, residual amounts of cosolvents and contaminants are expected to remain at levels that could preclude meeting regulatory requirements. However, with the bulk of the DNAPL extracted, in situ biotreatment becomes a viable “polishing” procedure transforming the remaining contaminants to non-hazardous compounds at a rate that may exceed the rate of dissolution or displacement. The efficacy of in situ bioremediation of chlorinated solvents is usually limited by transport and mixing considerations, i.e., the availability of electron donors at the appropriate concentrations relative to the concentration of chlorinated solvent (the electron acceptor). Concurrent exposure of microbes to an electron donor and electron acceptor can be facilitated by the delivery and extraction process as well as the co-solvency effect. A test of the Solvent Extraction Residual Biotreatment (SERB) technology was conducted in August 1998 at the former Sages Dry Cleaner site in Jacksonville, FL. The area is contaminated with tetrachloroethylene (PCE). The very low levels of biodehalogenation daughter products and the levels of dissolved oxygen suggest that natural attenuation processes are not protective of the site. A week-long in situ cosolvent extraction test with ethanol was conducted. Pre- and post-treatment partitioning tracer tests indicated that the estimated original 72 kg of DNAPL were reduced to 22.6 kg, or an approximately 70% removal of the original PCE. The dissolved mass of PCE in the treatment zone was estimated to be about 3.5kg. Post-test hydraulic containment was conducted for approximately 10 days until the ethanol concentration in the treatment system dropped below 10,000 milligrams per liter (mg/L). After pumping was ceased, ground-water monitoring indicated that, over time, biotransformation of the PCE was enhanced. After 4 months, significant levels of cis-DCE (4 mg/L), a PCE breakdown product, were detected in areas exposed to residual ethanol, and concentrations above 16 mg/L were observed after 10 months. Ethanol can be anaerobically degraded to acetate (incomplete oxidation) or carbon dioxide (complete oxidation). Depending on the extent of the oxidation, 1 to 2 moles of ethanol are required to drive complete dechlorination of one mole of PCE. The average post-containment concentration of ethanol in the cosolvent treatment zone was approximated 8,000 mg/L, or about 289 times the amount needed to remove the 21.1 moles of dissolved PCE or 38.8 times the amount of ethanol needed to degrade the estimated 157.1 moles of dissolved plus residual source PCE. This estimate assumes no competing terminal oxidation processes such as methanogenesis or sulfate reduction. Currently the system remains biologically active, and the dechlorination products TCE, cis-DCE, ethene, and chloride are accumulating. High levels of dissolved methane and hydrogen have also been detected in the treatment zone. The maximum and minimum observed rates of dechlorination (based on cis-DCE production) are approximately 43.6 and 4.2 µg/L/day, respectively. These rates can be extrapolated to a multi-step, concurrent, dechlorination process to predict that the dissolved phase PCE could be removed in 3 to 30 years, and that the total source zone PCE could be transformed in 24 to 240 years. For additional information, contact Guy W. Sewell (EPA/National Risk Management Research Laboratory) at 580-436-8566 or E-mail sewell.guy@epa.gov. Subsurface Biofilm Barriers for Contaminated Ground Water Containmentby Al Cunningham, Center for Biofilm Engineering, Montana State University; Randy Hiebert, MSE Technology Applications, Inc. Researchers at Montana State University’s Center for Biofilm Engineering (CBE), in collaboration with MSE Technology Applications, Inc. (MSE) of Butte, MT, have developed a process for building subsurface biofilm barriers (biobarriers) to contain dissolved contaminant plumes. Biofilm barriers are developed by injecting large numbers of mucoid bacteria into permeable strata formations. The bacteria are mixed with water and pumped down a series of injection wells. A suitable growth substrate and additional nutrients then are injected to stimulate microbial growth. These mucoid bacteria are capable of forming large quantities of extracellular polymer material (EPS) during their growth phase. Bacterial growth and EPS production form microbial biomass which substantially reduces the free pore space in the formation and consequently reduces the hydraulic conductivity. This zone of reduced hydraulic conductivity serves as a novel barrier technology for controlling off-site migration of mobile contaminants. Biobarrier technology also may be a useful means of funneling contaminated ground water through subsurface treatment systems (i.e., zero-valent iron systems). The main advantages offered by biobarrier technology are: 1) biobarrier construction is achieved without excavation and therefore will be economically attractive at many sites; and 2) there is no obvious depth limitation for biobarrier technology. Traditional subsurface barrier technologies such as slurry walls and grout curtains are not usually cost effective at depths more than 50 feet. Laboratory Investigation CBE conducted a 4-year laboratory investigation to understand factors which promote or retard biofilm accumulation in porous media with the intent to apply such understanding toward the manipulation of permeability and mass transport properties. Biofilm formation and persistence experiments were conducted in porous media columns and in lysimeters. Accumulation of biomass in the columns and lysimeters resulted in a reduction of hydraulic conductivity to less than 0.1 percent of original values. Results indicated that biobarrier integrity was unaffected by expo-sure to 300 mg/L of carbon tetrachloride and heavy metal contaminants (strontium and cesium) at concentrations of about 1 mg/L for periods up to 120 days. These laboratory-scale results indicated that the ability of microbial biobarriers to manipulate the hydrodynamic properties of porous media could result in an effective technology for the containment of ground-water contaminants. Field Demonstration Working in collaboration with MSE, the project team constructed a field demonstration lysimeter facility in Butte, MT to develop a comprehensive data set for the evaluation of biobarrier performance. The field test began in December, 1999 and is still in operation. A 180-foot long and 20-foot deep biobarrier was constructed in a lysimeter that was 130 feet wide, 180 feet long, 20 feet deep, and lined with impermeable plastic. A highly mucoid Pseudomonas strain was used as the microbial inoculum, and molasses was the primary growth substrate; nitrate was added to serve as the primary electron acceptor after oxygen was depleted. A flow field was established across the 180-foot dimension by injecting supply water at the up-gradient boundary and simultaneously pumping from a series of recovery wells located at the down-gradient boundary, and the system was operated to maintain a constant hydraulic gradient across the barrier. The integrity of the barrier was determined by measuring the reduction in hydraulic conductivity within the barrier region. Hydraulic conductivity was measured by slug tests performed in the 11 injection wells which spanned the 180-foot dimension. To date, six sets of slug test data have been measured. As the 180-foot biofilm barrier developed, the overall hydraulic conductivity through the lysimeter steadily diminished. Hydraulic conductivity reductions of more than 99 percent were measured across the barrier. Cost A cost analysis was performed by MSE using information obtained from the 180-foot lysimeter biobarrier investigation and other field data. Results indicated a net present cost for installation and long-term maintenance for biobarriers in the range of $7 to $10 per cross-sectional square foot. These costs compare favorably with alternative barriers such as sheet piling which has costs in the range of $25 to $60 per cross-sectional square foot. For further information contact Randy Hiebert (MSE) at 406-494-7233 or E-mail hiebert@mse-ta.com, or Dr. Al Cunningham (CBE) at 406-994-6109 or E-mail al_c@erc.montana.edu.

|