- Sequential Thermodesorption and Non-Combustion Decomposition Technologies Destroy Dioxins and Pesticide Waste

- EPA Evaluates Cost and Performance of Blood Meal-Enhanced Anaerobic Bioremediation of Toxaphene-Contaminated Soil

- Combined Mechanical/Chemical Process Removes POPs from Soil and Sediment

- In-Situ Thermal Remediation Completed on Wood-Treatment Waste

Environmental contamination by persistent organic pollutants (POPs) poses significant challenges due to their chemical stability, tendency to bioaccumulate, and ability to easily disperse. Of the 12 globally recognized POPs, nine are pesticides and the remaining three are industrial chemicals (PCBs) or industrial byproducts (dioxin and furans). As highlighted in this issue of Technology News and Trends, degradation or destruction of POPs often relies on ex-situ technologies combining thermal, physical, and/or chemical processes, but increasing numbers of less costly bioremediation and thermal applications are successful in-situ.

Sequential Thermodesorption and Non-Combustion Decomposition Technologies Destroy Dioxins and Pesticide Waste

CLU-IN Resources

CLU-IN's "Contaminant Focus" on POPs provides assorted technical reports, background information, and links concerning remediation strategies. Users may download documents such as EPA's Reference Guide to Non-Combustion Technologies for Remediation of Persistent Organic Pollutants in Stockpiles and Soil, or the United Nations Environment Programme's Review of Emerging, Innovative Technologies for the Destruction and Decontamination of POPS and the Identification of Promising Technologies for Use in Developing Countries. Visit CLU-IN at http://www.cluin.org/POPs.

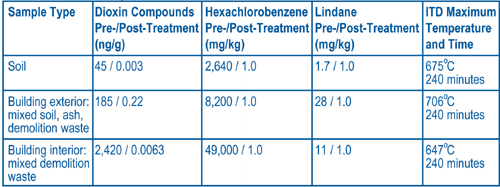

An onsite ex-situ process combining indirect thermal desorption (ITD) with Base-Catalyzed Decomposition™ (BCD) is operating in semi-process mode at the former Spolana chemical manufacturing complex in Neratovice, Czech Republic. Over the course of operation, the ITD and BCD plant will treat POPs in 35,000 tons of soil and contaminated building rubble, 1,000 tons of contaminated concentrate generated by first-stage thermal desorption, and 200 tons of pesticide waste intermediate compounds. Based on the results of pilot-scale operations showing that the combined treatment approach reduced contaminant concentrations to below cleanup criteria, full-scale operations began in January 2007.

Manufacturing at this site, located just north of Prague along the Elbe River, dates back to 1939, but releases of POPs became pronounced in the 1960s when production focused on agricultural chemicals, PVC, and components for Agent Orange. Site characterization from 2001 through 2005 identified high levels of POPs in soil surrounding two of the abandoned manufacturing buildings, including concentrations reaching approximately 1,300 mg/kg hexachlorobenzene, 45,000 ng/kg dioxin toxic equivalency (TEQ), and 200 mg/kg lindane. The Czech Environmental Inspection established site-specific cleanup levels for soil and solid waste at 1 ng/g for dioxin and 5 mg/kg for the sum of other chlorinated pollutants such as hexachlorobenzene, lindane, DDD, DDE, DDT, tetrachloro-benzenes, and pentachlorophenol.

Pre-treatment work involved enclosing the two condemned buildings and constructing a 6,000-m² decontamination facility. In the first stage of treatment, 30-kg batches of contaminated soil and other media are transferred to an ITD chamber (rotating kiln) to remove organic contaminants. The desorption chamber is electrically heated to approximately 600°C, and to over 700°C for some batches.

Continuous introduction of nitrogen to the desorption chamber ensures exclusion of oxygen, thereby preventing formation of additional dioxins such as polychlorinated dibenzo-p-dioxins (PCDDs) and poly-chlorinated dibenzofurans(PCDFs). Heated nitrogen gas containing gaseous desorption products is directed to a dust filter with ceramic fiber elements and then to water-cooled condensers, where gas temperatures decrease to 20-25°C and most desorption products condense. Trace amounts of contaminants remaining in cooled air are trapped in a two-stage activated carbon filter.

In the second treatment stage, collected or condensed PCDDs, PCDFs, pesticides and other POPs are fed into a BCD reactor for non-combustion destruction. Chemical destruction occurs in the presence of a reagent mixture of sodium hydroxide, a hydrogen donor (hydrocarbon), and a catalyst. Blending of this mixture at 290-350°C within the reactor’s nitrogen-rich environment releases highly reactive hydrogen capable of cleaving chemical bonds in target compounds. Depending on contaminant concentrations, treatment duration ranges from several to 90 minutes. This process releases no greenhouse gases and creates byproducts containing non-toxic carbon residue and anionic sodium salts that are disposed at offsite land disposal facilities.

Reactor steam is transferred into a condensation system consisting of two water-cooled condensers and a supercooling condenser further reducing temperatures to 8°C. The cooled gas is passed through a two-stage activated carbon filter system prior to atmospheric release. Inorganic salts and carbon residue are separated from the unreacted oil by gravity or centrifugation, and the oil and catalyst may be recovered for reuse in other treatment cycles. Excess salts and base may be removed from carbon residue by washing with water.

Destruction efficiencies observed in selected samples after ITD treatment during the current full-scale operation are similar to those derived from pilot-scale testing in 2004 (Figure 1). Treatment through sequential ITD and BCD reduced target contaminants by 99% in system outfeed. Destruction efficiencies slightly vary, depending on waste form and contaminant content. Cleanup closure is anticipated in late 2008, at which time the treatment facility will be dismantled and transferred to another site for use. Total project costs are estimated at $90 million.

Each of the two 10-m³ BCD reactors employed at Spolana is capable of treating 1,000 tons/yr of high chlorine-content (50%) PCBs or pesticides, 2,000 tons/yr of contaminated filter dust, or up to 7,000 tons/yr of oil with moderate to low PCB content. Depending on treatment volume and facility size, typical BCD equipment may cost from $500,000 to $2,500,000; transportable plants with 2.5-m³ reactors may be used for smaller treatment volumes. Originally developed by the U.S. EPA’s Risk Reduction Laboratory, this technology has undergone commercial development involving refinement to the BCD catalyst over the past 10 years.

Alternate pre-treatment such as crushing of large soil particles or adjustment of pH or moisture content may be required. Pilot- and full-scale applications indicate that the technology may be used to destroy chlorinated or non-chlorinated organics in soil, sediment, solids, liquids, or sludge.

Contributed by Richard Pribyl, Czech Ministry of the Environment (richard_pribyl@env.cz), Martin Kubal, Institute of Chemical Technology in Prague (martin.kubal@vscht.cz or +420 2 24355029), and Grahame Hamilton, BCD CZ (grahame.hamilton@bcdcz.cz or +420 2 22922612)

EPA Evaluates Cost and Performance of Blood Meal-Enhanced Anaerobic Bioremediation of Toxaphene-Contaminated Soil

The U.S. EPA Environmental Response Team Center (ERTC) initiated field-scale studies in January 2001 on the use of anaerobic bioremediation for treating toxaphene-contaminated soil at the Gila River Indian Community (GRIC) site in Chandler, AZ. In early 2003, a similar remediation strategy was formulated for the Gila River Boundary (GRB) site near Laveen, AZ, and another toxaphene-contaminated site of the GRIC Reservation. Both applications used blood meal as a nutrient to stimulate contaminant degradation by indigenous anaerobic microorganisms. Using a toxaphene cleanup goal of 17ppm, ERTC and EPA Region 9 recently evaluated the performance and cost of these large-scale anaerobic applications.

The GRIC site once served as an airstrip for crop dusters that applied pesticides (primarily toxaphene). Discarded pesticide residue and runoff from equipment washing contaminated extensive areas of soil that eventually was excavated and transported to a designated area on the reservation for treatment. Approximately 3,500 yd³ of the contaminated soil were mixed and placed in four 178- by 43-foot anaerobic cells sloping to 7 feet in depth. Using a large-scale pugmill, blood meal and sodium phosphate (as pH buffer) were combined in a ratio of 5:1, with equal amounts of dibasic and monobasic phosphate salts added to protect pH from alkaline ammonia produced by the blood meal. This amendment then was mixed with the soil in the treatment cells.

Pre-treatment soil samples were collected from the cells prior to amendment. Toxaphene concentrations ranging from 29 to 34 mg/kg of soil before treatment decreased to 4-5 mg/kg after six months of treatment, resulting in an average removal rate of 86-93% for all four cells.

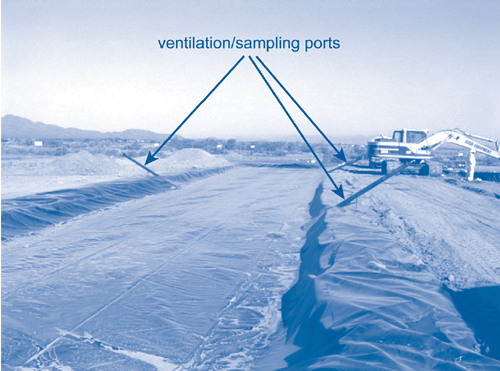

Soil contamination at the GRB site resulted from pesticide spills. In 2004, after treatment at GRIC was underway, EPA began treating approximately 8,000 yd³ of toxaphene-contaminated soil in six 100- by 20-ft by 10-ft-deep field cells (Figure 2). Before adding similarly amended contaminated soil, each cell was lined with an oversized plastic liner that was folded, glued together, and buried on edges to create a cover after cell loading. Prior to covering, the cells were flooded to achieve a 6- to 12-inch depth of free-standing water needed to establish and maintain anaerobic conditions for reductive dechlorination by indigenous bacteria.

After six months of treatment, toxaphene concentrations in soil decreased from initial concentrations of 23-110 mg/kg to 5-20 mg/kg, below the action level in all six treatment cells. The average removal rate ranged from 66 to 82%. Approximately 6,100 m³ of contaminated soil were treated over two years of cell operation, and cleanup was completed in early 2006. At that point, the liner was punctured and left in place with the treated soil.

Bioremediation at both sites involved cell liners, microbial-enhancing flooding, and sampling/ventilation ports for monitoring the treatment cells and maintaining the cover through off-gas. Due to high rates of evaporation and a deep water table, construction of a water collection system was not required. The same amendments were used at both sites, with one exception: based on preliminary results from the GRIC application, EPA determined that approximately 50% less blood meal was required for effective soil treatment. At the GRB site, this fraction of blood meal was substituted with less costly starch. EPA believes that facultative anaerobes in the contaminated soil use the starch rather than the blood meal during their early growth phase, when driving out remaining oxygen.

Other improvements were made to reduce project costs at the GRB site. Use of larger treatment cells accommodating the high soil volume, nearly double the GRIC volume, achieved savings through economy of scale. Streamlining of field activities by deploying the same contractor team at both sites also reduced costs. Overall, the shorter treatment period needed to meet cleanup goals at the GRB site saved significant costs related to longer-term monitoring/sampling.

The total cost for soil cleanup at GRIC is estimated at $725,000 or approximately $271/m³, while cleanup at the GRB site is estimated at $793,000 or approximately $130/m³. These costs are competitive with other cleanup methods such as onsite incineration and soil washing, which may range from $290-430/m³ and $135-290/m³, respectively. ERTC anticipates future studies to identify more cost-effective nutrient recipes for promoting rapid degradation of toxaphene. Additional sites are targeted for evaluation of blood meal-based anaerobic bioremediation of soil containing other chlorinated pesticides such as DDT.

Contributed by Harry L. Allen, U.S. EPA ERTC (allen.harry@epa.gov or 732-321-6747) and Harry L. Allen IV, U.S. EPA Region 9 (allen.harryl@epa.gov or 415-972-3063)

Combined Mechanical/Chemical Process Removes POPs from Soil and Sediment

The New Zealand Ministry for the Environment and Tasman District Council are collaborating in cleanup and reuse planning for the Fruitgrowers Chemical Company (FCC) site, the country's most highly contaminated area. An onsite demonstration was conducted in 2004 to evaluate performance of an innovative technology using mechanical energy to promote reductive dehalogenation of POPs in soil and sediment. Successful demonstration results for Mechanochemical Destruction™ (MCD) led to full-scale application of the technology later that year to treat surface and subsurface material containing high concentrations of DDT, DDD, DDE (collectively DDX), aldrin, dieldrin, and lindane (collectively ADL). Over the course of treatment, nearly 65,000 m³ of soil/sediment, comprising 200 individual cells segregated into 600 0.5-m layers, will be excavated for ex-situ remediation (Figure 3).

The 4.2-ha FCC site was used for pesticide production from 1932 until 1988 when operations ceased and the site was abandoned, leaving large areas of contaminated soil and sediment. The site borders a recreational estuary, residential area, tourist attractions, and restaurants in the coastal town of Mapua at the top of the South Island. Site characterization on a 15-m grid at a 2-m depth confirmed hot spots exceeding 12,000 ppm DDX and 400 ppm ADL, and ex-situ pilot tests showed concentrations reaching 2,600 ppm and 100 ppm, respectively. This characterization gave rise to an estimated 6,600 m³ of soil requiring MCD treatment. Approximately 85% of the soil exceeding the soil acceptance criteria (SAC) has been remediated to levels generally 50% below the SAC.

Based on the site's anticipated use for commercial and recreational purposes, the SAC were set at 200 ppm DDX and 60 ppm ADL at depths greater than 0.5 m, and at 5 ppm DDX and 3 ppm ADL at depths less than 0.5 m. Cleanup plans require the use of uncontaminated onsite soil or imported soil for the 0.5-meter top layer in the site's anticipated commercial/recreational areas and for the full depth of planned residential zones.

During the MCD preconditioning phase, layers of the target soil are excavated and sorted through a 3-part screen to obtain a particle-size fraction below 20 mm. This fraction is dried in a diesel-fired rotary drum unit at temperatures not exceeding 120°C to achieve moisture content below 2%, and sorted again in an aggressive rotary screen to obtain a particle fraction less than 10 mm that is further separated into coarse or fine streams. Analytical testing of the 10- to 20-mm extracted fraction on a volumetric basis consistently indicates contaminants are successfully "knocked off" during rotary screening to achieve DDX and ADL concentrations at or below the target level; the fraction is stored in an onsite silo for later placement across the site. Gaseous emissions throughout this conditioning process are treated through a conventional air emission treatment system, and captured particulate contaminants are added to infeed of the system's mechanochemical reactor.

MCD treatment involves blending readily available commercial reagents, collectively less than 2% by dry weight, with contaminated soil/sediment as it is transferred from a separate storage silo to the mechanochemical reactor. The reagent blend contains a base metal (typically an alkali-earth metal, such as iron) and a hydrogen donor. The reactor employs conventional vibratory ball-mill technology to rupture soil crystals and form reactive free radicals on the ruptured soil surfaces. Crystal rupturing is accompanied by emissions of electrons and photons and generation of electrostatic charges, a combination known as "triboplasma." An organic pollutant within the triboplasma zone typically becomes excited and reacts with the highly reactive free radicals, resulting in formation of inorganic halides and graphite carbon. Two horizontally mounted vibratory tubes within the reactor drive these chemical reactions.

Dried material of particle size less than 10 mm is fed into the MCD reactor through separate streams of fine and coarse fractions on a continuous basis. After a residence time averaging 15 minutes at a temperature of 70-100°C, material is transferred out of the reactor, stockpiled, and analytically sampled prior to onsite placement. The MCD currently processes an average of 100 m³ of material each week.

By early December 2006, a total soil/sediment volume of 55,250 m³ (85% of the target volume), was excavated, screened, relocated or treated onsite. Of this volume approximately 5,500 m³ have been treated by the MCD process to date. Pre- and post-treatment analyses of total chlorine and carbon content show that carbon and chlorine concentrations are constant, indicating that a mechanochemical reaction rather than a volatilization process is occurring within the MCD reactor. Treatment byproducts primarily consist of non-hazardous organics and metal salts. Application at Mapua as well as pilot testing at other sites indicate that this technology also treats mixed solid-liquid waste effectively but may be limited in treating high-moisture clay.

Contaminated soil and sediment from portions of the site not targeted for MCD treatment were excavated and relocated dependant on the end use criteria. Cleanup completion is scheduled for March 2007 at a total project cost of approximately $8 million, including construction and continuous operation of the entire facility for 2.5 years. Upon cleanup closure, the Tasman District Council anticipates allocating 40% of the land for public open space. Pending final results, the Ministry for the Environment anticipates that this project will serve as a prototype for remediating other POP-contaminated sites in New Zealand.

Contributed by Bryan Black, Environmental Decontamination Ltd. (bblack@edl.net.nz or +64 21 960069) under permission of New Zealand Ministry of the Environment

In-Situ Thermal Remediation Completed on Wood-Treatment Waste

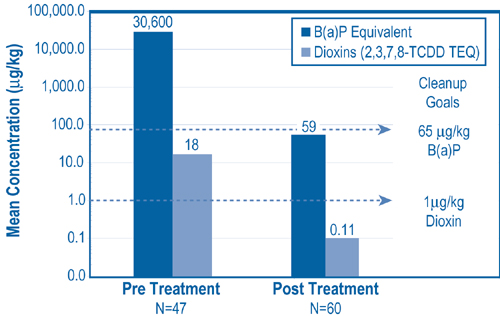

After four years of operation, full-scale in-situ thermal remediation of soil at Southern California Edison's former wood treatment site in Alhambra, CA, concluded last spring. Subsurface soil containing PAHs, PCP, and dioxins/furans was treated by in-situ thermal desorption (ISTD), a technology employing the simultaneous application of thermal conduction heating and vacuum to treat soil without excavation. Treatment achieved cleanup goals for approximately 16,500 yd³ of predominantly silty soil to a depth of 105 ft, and provided the opportunity for property reuse without restrictions.

The treatment area included the locations of four below-ground creosote "dip" tanks formerly used to preserve utility poles, an aboveground storage tank farm, a boiler house, and decommissioned pipelines that remained in place during ISTD treatment. The mean (and maximum) concentrations of contaminants targeted during soil treatment were 2,306 (35,000) mg/kg total PAH, 0.018 (0.194) mg/kg dioxins/furans (TEQ), and 2.94 (58) mg/kg PCP. Due to the large treatment area and associated electrical power constraints, remediation occurred in two phases. Phase 1 operated from 2002 through early 2004 and was immediately followed by phase 2 operations, which continued until September 2005. Site-specific risk assessment established cleanup goals for contaminants of concern: 0.065 mg/kg PAHs (based on benzo(a)pyrene equivalents [B(a)P-E]), 1 µg/kg dioxins/furans (based on TCDD TEQ), and 2.5 mg/kg PCP.

ISTD employs a network of horizontal or vertical heater-only and heater-vacuum wells containing electrically powered heating elements with maximum operating temperatures of 600-800°C. Silicon-controlled rectifiers are used to control output of the heating elements. Through direct surface contact and conductivity, heated wells raise the temperatures of surrounding soil. As soil is heated, organic contaminants are vaporized and drawn toward the heater-vacuum wells. The vapors pass through the superheated zone surrounding the heater-vacuum wells, where potentially 99% of contaminant destruction occurs. Mechanisms responsible for contaminant destruction and/or vaporization include evaporation, steam distillation, boiling, oxidation, and pyrolysis. Remaining trace contaminants are removed in an aboveground air quality control (AQC) system.

Treatability tests were conducted to determine optimal operating temperatures and residence times. Testing confirmed that successful treatment of high-boiling point PAHs occurs at temperatures significantly lower than their boiling points. Modeling indicated that exposure of this site’s PAH-contaminated soil to temperatures of 335°C over three days would reduce contaminant mass more than 99.9%. Limitations of the AQC system, however, prevented operation of all ISTD heaters at the full design temperature in areas of high contaminant mass. Based on earlier laboratory evaluation of PAH oxidation rates, it was determined that achieving a slightly lower temperature for a longer duration would achieve site-specific cleanup goals. A treatment paradigm was designed to sustain a 300°C operating temperature for thirty days. Overall treatment duration was driven by the last location of the treatment zone to achieve target temperature.

Field preparations began with installation of 654 heater-only and 131 heater-vacuum wells in a triangular pattern to average depths of 20 ft across the 31,430-ft² treatment zone. A light cement aggregate layer was constructed over the surface to prevent subsurface heat loss during phase 1. Based on phase 1 results, polystyrene insulating board was added to the phase 2 cover between a bottom layer of light aggregate material and a top layer of insulating cement. Two 2,500-kVA transformers were installed to provide power for the ISTD system, including the vacuum blowers, AQC system, and well heaters.

The vacuum blower system included magnehelic gauges for monitoring well-field vacuum and ensuring that field boundaries remained under negative pressure. Thermocouples encased in steel pipe were placed at 164 temperature-monitoring points; some thermocouples were installed adjacent to the heating elements, while others were installed in cooler centroid locations in order to track heat migration through the subsurface. Air monitoring activities included monthly compliance tests, continuous tracking of AQC system emissions, and four source-test events. The source tests involved analysis of air samples at the AQC influent and effluent as well as locations between the thermal oxidizer and each granular activated carbon (GAC) vessel. Well-field vacuum data were collected at 18 monitoring points three times daily, and vacuums were adjusted if needed.

Post-treatment analysis of soil samples (60 for PAHs, 18 for dioxins/furans) taken from shallow, mid-depth, and deep soil cores at 25 treatment-zone centroid locations showed contaminant reductions exceeding 99% (Figure 4). The average post-treatment concentration for PCP was 1.25 mg/kg, and sitewide means for dioxins/furans (TCDD TEQ) and PAHs (B(a)P-E) were 0.11 µg/kg and 0.059 mg/kg, respectively, all below remediation goals.

Daily measurements of carbon dioxide concentrations in stack gas indicate that a total hydrocarbon mass of 870,000 lbs (expressed as naphthalene) was removed from soil during the entire project. Additional but unmeasured contaminant mass likely was destroyed as a result of in-situ pyrolysis and oxidation. Pre- and post-treatment measurements of soil hydraulic conductivity and porosity indicated that ISTD did not significantly impact soil properties.

Factors to be considered in future ISTD applications include: (1) Additional characterization of a facility’s former infrastructure (obscuring high contaminant mass) may lead to the use of a higher-capacity vapor-treatment system over a shorter treatment time. (2) Enhanced surface covers are needed to maximize vapor seal, minimize heat loss, and prevent surface-water infiltration; rigid polystyrene insulation is susceptible to degradation and should be avoided. (3) Horizontal collectors or shallower heater-vacuum well screens, connected into a coarse-textured fill layer above the treatment zone, would accelerate removal of contaminated vapors and steam. (4) ISTD efficiency at sites with non-aqueous phase liquids or high contaminant mass may be maximized through a phased approach such as thermally enhanced free-product recovery followed by high-temperature treatment.

ERRATA

In the November 2006 article "Emulsified-Oil Biobarrier Provides Long-Term Treatment of Perchlorate/VOC Plume," contaminants were erroneously printed in unit measures of "mg/L" rather than "µg/L." Readers are requested to note the following correction: Average concentrations of target contaminants in the treatment area were 9,000 µg/L perchlorate, 11,000 mg/L TCA, 50 µg/L PCE, and 90 ug/TCE.

The total project cost was $13 million, estimated to be 40% lower than soil excavation. Costs for ISTD implementation at sites with similar settings could potentially be reduced 47% by applying lessons learned during the Alhambra application.

Contributed by Tedd Yargeau, Cal EPA Department of Toxic Substances Control (tyargeau@dtsc.ca.gov or 818-551-2864) and John Bierschenk, TerraTherm, Inc. (jbierschenk@terratherm.com or 978-343-0300)