Steam Injection Combined with Electrical Resistance Heating at the Young-Rainey STAR Center

The U.S. Department of Energy (DOE) completed the first phase of a full-scale remediation project this past fall to remove non-aqueous phase liquid (NAPL) at a corner of the Young-Rainey STAR Center (formerly the Pinellas Plant) in Largo, FL. A combination of steam injection and electrical resistive heating was used in an area covering 10,000 ft2 and extending to a depth of 35 ft. Final analysis of the project indicates considerably higher success than anticipated, with all cleanup targets for both soil and ground water being met.

NAPL containing principally trichloroethene (TCE) and dichloroethene (DCE) was discovered at the STAR Center in 1998. Field investigations revealed an estimated mass of 5,500 lbs of NAPL and volatile organic compounds within the target area. Concentrations of TCE and DCE were as high as 360 mg/L and 450 mg/L, respectively. Cleanup goals for TCE were set at 20.4 mg/kg in soil and 11 mg/L in ground water. DCE cleanup goals were set at 71 mg/kg in soil and 50 mg/L in ground water.

The site is located in a swampy area with silty clay and sandy silt overlaying a clay aquitard 30 ft below ground surface. Dense NAPL pools were identified directly above the aquitard (Figure 1), and were suspected to exist atop the sandy silt layer within the alluvium. Previous research indicated that contaminant concentrations were too high to use bioremediation, but that conditions favored using thermal technologies to remediate both soil and ground water.

Construction of the treatment systems began in May 2002 with the installation of 21 steam injection wells placed at 20-ft intervals along the perimeter of the treatment area. A network of 28 ground water extraction wells with 20-ft screens was installed in the center. To provide additional heat to the underlying confining area, 30 electrodes spaced at 20-ft intervals were installed on the confining layer and an additional 21 electrodes were installed in steam injection wells within the treatment zone.

Prior to the commencement of steam injection, soil around the perimeter of the treatment area and the aquitard itself were heated to a temperature of 160ºF using five 400-kW power generators to pass electrical current through the soil. Steam generated by two 6-million-BTU boilers was distributed on a pulsed basis through the injection wells at rates of 100-5,000 lbs/hr. The combined technologies converted contaminants to vapor that could move more readily through the soil. The resulting steam front pushed vapors toward the central network of extraction wells for eventual removal and treatment at an existing above-ground facility. Treatment of the extracted vapor with regenerative granular activated carbon was required prior to atmospheric discharge.

After four and a half months of operation, preliminary sampling indicated that the target cleanup levels for both soil and ground water had been met. The systems were shut down at that point and allowed to cool for six months. Confirmatory sample analysis conducted six months after operations had stopped showed that TCE and DCE concentrations decreased approximately 99% in ground water and soil. Only 4 of more than 400 samples revealed contaminant concentrations exceeding their maximum contaminant levels. Sample analysis also showed that thermal treatment had not increased movement of NAPL to outlying areas.

The total project cost (including design, construction, operations, demobilization, and preparation of the final report) was approximately $3.8 million. DOE's complete project report, Northeast Site Area A Final Report, is available at http://www.gjo.doe.gov. Due to the success of the first phase of NAPL removal, DOE now is planning to apply the combined technologies at a 1-acre area nearby. Construction of the second thermal system is expected to begin in July 2004, with operations scheduled to begin in July 2005.

Contributed by David Ingle, DOE Office of Legacy Management/LM-50 (727-541-8943 or David.Ingle@gjo.doe.gov)

Biological PRB Used for Perchlorate Degradation in Ground Water

The U.S. Navy is evaluating performance of a full-scale, in-situ permeable reactive barrier (PRB) constructed in 2002 at the Naval Weapons Industrial Reserve Plant McGregor (NWIRP McGregor) to biologically degrade perchlorate plumes in ground water. Project monitoring indicates that the perchlorate concentration consistently decreases to a non-detect level in ground water that has passed through the PRB system. Based on this success, the U.S. Navy anticipates implementing biological PRB systems over the next two years at additional areas of the installation.

The 9,700-acre NWIRP McGregor is located in an agricultural region approximately 20 miles southwest of Waco, TX. Until the facility closed in 1995, the site was used to manufacture and test rocket motor propulsion systems. Operations involved the use of ammonium perchlorate, which is highly soluble in water and disassociates readily into ammonia gas and perchlorate ion (ClO4-) upon contact with water. Investigations conducted at that time revealed perchlorate concentrations in ground water exceeding 91,000 ppb. The contaminant plumes are located primarily in the upper portions of an unconfined 5- to 35-ft-thick bedrock aquifer exhibiting decreased (limestone) fracturing and weathering with increased depth. Ground water in this region seasonally varies from depths of 2-10 ft below ground surface, with a flow velocity ranging from 0.13 to 3.0 ft/day.

An in-situ pilot study was conducted in early 2002 to evaluate efficacy of a biological PRB in treating perchlorate at one of the NWIRP McGregor source areas. The pilot system consisted of five 10- to 15-ft-deep trenches of lengths of 75-100 ft and widths of 18-24 in. Earlier testing indicated that both vertical and horizontal migration of the amendments would occur.

The trenches were filled with a mixture of gravel and carbon material (wood chips) in a 7:1 ratio. Microbial consumption rates of various forms of wood chips were tested: alone, with the addition of acetate, and soaked with soybean oil or a soybean oil/mushroom compost mixture. The addition of carbon sources acting as electron donors changed ground-water conditions from aerobic to anaerobic. Through this process, indigenous bacteria were enabled to use perchlorate (ion) as respiratory oxygen until it was depleted and only (non-toxic) chloride remained.

Perchlorate concentrations in ground water entering the pilot trenches were 700-800 ppb prior to treatment, while ground water exiting the trenches contained concentrations below the laboratory detection limit (0.43 ppb). Exiting ground water also had high total organic content and low oxygen/reduction potential (ORP), which indicated microbial activity was occurring within the trenches. Sample analysis of exiting ground water showed that the concentration of TCE, a co-contaminant, also decreased from 300 ppb to a non-detect level as a result of treatment. Seasonal rainfall variations influencing ground-water flow were not found to affect trench performance adversely. Sample analysis of ground water entering and exiting the trenches will continue on a quarterly basis in order to acquire long-term performance data.

The unexpected presence of floating edible oil after an oil pump test required the PRB design to be modified to include stand-alone sampling ports, which helped to avoid oil during sampling. The pilot study indicated that the highest rate of perchlorate degradation was achieved in trenches where oil-saturated wood chips were added, with or without mushroom compost. Monitoring data collected over the year-long pilot study test suggest that carbon rejuvenation of a full trench (using a soluble carbon source such as vegetable oil or molasses) should occur in a single event on an annual or biennial basis. The onsite pilot trenches were designed with internal piping systems that will allow for injection of liquid carbon when ORP data indicate that trench rejuvenation is necessary. Rejuvenation will occur until perchlorate concentrations drop below the state’s drinking water standard of 4 ppb. Due to the extent of ground-water contamination (7 plumes encompassing 2,800 acres), reaching this standard may take 30 years.

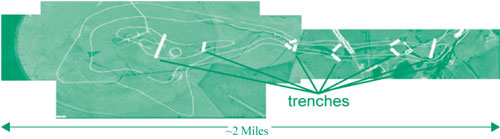

Based on early results of the pilot study, a full-scale PRB system employing 3,500 linear feet of trenches was constructed in late 2002 to address a perchlorate plume migrating offsite. To eliminate the potential for water to seep to the surface under high ground-water conditions, segments of trenches were installed in a pattern alternating with non-trenched segments along the plume pathway. Piezometric contours were used to select the length of each trench, which range from 100 to 750 ft long. Seven trench segments were installed on 1,000-ft centers in a gallery fashion (Figure 2), and each was backfilled with a mixture of gravel (70%), mushroom compost (20%), and soybean oil-soaked woodchips (10%). Approximately 4,200 tons of material were used to backfill the trenches.

Ground water entering the trench located closest to the source area contains an average perchlorate concentration of 13,000 ppb. Upon exiting the trench, however, the concentration decreases to a level below the detection limit. System monitoring over the first three months of PRB operation indicated that the treatment envelope of a single trench had traveled a distance of 400 ft downgradient, where it reduced the perchlorate concentration in a monitoring well by 99% from a pre-treatment concentration of 1,000 ppb.

Offsite trenches were designed to remediate the contaminant plume in 15 years or less, thereby avoiding the need for institutional controls. Due to a projected PRB lifespan of 8-15 years, replacement of the solid organic material (woodchips and mushroom compost) may be required. The cost of constructing and operating the trenches in both scales of operation is approximately $150/linear foot. Overall, the Navy estimates a capital cost avoidance of $3 million as a result of using this technology instead of conventional ex-situ options such as ground water pumping and treatment.

Contributed by Mark Craig, U.S. Navy/NAVFAC South Division (843-820-5517 or craigm@efdsouth.navfac.navy.mil) and Alan Jacobs, EnSafe (901-372-7962 or ajacobs@ensafe.com)

Integrated Methods for Characterizing a Fractured-Rock Aquifer

In 1990, the U.S. Geological Survey (USGS) began developing and testing field techniques and interpretive methods to characterize ground-water flow and chemical migration in the fractured-rock aquifer of the Mirror Lake watershed in central New Hampshire. Investigation results showed that data from multiple hydrogeologic disciplines were required to identify fractures, their hydraulic significance, and their hydraulic connectivity. An integrated approach using data from geologic and fracture mapping, surface and borehole geophysics, ground water modeling, hydraulic testing, and geochemical and isotopic methods is needed to develop a defensible site conceptual ground water model for a fractured-rock aquifer.

In 1998, the University of Connecticut assembled a multidisciplinary team including USGS researchers to use this approach in characterizing the nature and extent of contamination in soil, ground water, and surface water in the area of a landfill and former chemical-waste disposal pits in Storrs, CT. Sampling of domestic wells in the mid-1980s had indicated the presence of volatile organic compounds in area ground water. To characterize the fractured-rock aquifer and help assess remediation alternatives, the team developed a conceptual model using integrated multidisciplinary data.

- Resistivity soundings were used to define the orientation of geologic features. Results indicated a dominant bedrock fracture strike direction consistent with local geologic maps. Additional soundings verified by aerial photography helped to interpret the orientation of waste disposal cells in the landfill.

- Two-dimensional (2-D) resistivity profiles indicated a landfill thickness of 10-15 meters.

- Conductivity profiles combined with 2-D resistivity surveys detected conductive anomalies interpreted to be leachate plumes near two surface-water discharge areas: (1) a shallow plume dissipating about 45 meters north of the landfill, and (2) a deeper plume existing in overburden and shallow bedrock along an intermittent drainage area southwest of the landfill.

- Eleven bedrock boreholes were installed at 35- to 90-meter depths to further characterize anomalies detected with surface-geophysical methods and to obtain hydraulic data, ground-water samples, and fracture characteristics.

- Heat-pulse flowmeter logging collected under ambient and pumped conditions identified several transmissive fractures and ambient vertical flow between some of the fractures. These results indicate a hydraulic potential for cross contamination within boreholes open to multiple fractures.

- A multifunctional bedrock aquifer transportable testing tool (BAT3) (Figure 3), recently developed by the USGS, was used temporarily to isolate sections of the borehole to collect discrete-interval ground-water samples, identify hydraulic head as a function of depth, and conduct single-hole hydraulic tests that helped identify hydraulic properties of fractures.

- Discrete-zone monitoring systems were installed soon after well drilling and borehole logging to provide a method for long-term discrete-interval sampling and to determine hydraulic head, connections between transmissive zones within fractured rock, and the extent of connection between fractured rock and surficial aquifers. These systems prevented cross contamination between borehole fractures.

Hydrogeologic characterization of the Storrs landfill area demonstrates the importance of a multidisciplinary approach for characterizing contamination in a fractured-rock aquifer. The project also highlights the need for collecting discrete-interval hydraulic-head and water-chemistry data, which were used to produce a conceptual ground-water model for designing final site remediation. Additional information on approaches for integrating these and other characterization tools is available from the USGS Toxic Substances Hydrology Program web site at http://toxics.usgs.gov, and the USGS Office of Ground Water, Branch of Geophysics web site at http://water.usgs.gov/ogw/bgas/.

Contributed by Carole Johnson, USGS (860-487-7402 or cjohnson@usgs.gov), F.P. Haeni, USGS Emeritus, and Allen Shapiro, USGS (703-648-5884 or ashapiro@usgs.gov)