Both light and dense nonaqueous phase liquids (LNAPLs and DNAPLs) are prevalent environmental contaminants. NAPL contamination may occur as free product, sorbed to the matrix, and in the dissolved phase plume. Increasing understanding of the different phases and locations in which contamination may occur at NAPL sites—and their interactions—has led to increasing use of several treatment technologies operating in parallel or in series as a treatment train. More frequently, treatment trains for NAPL include innovative remedies such as in-situ thermal, in-situ chemical oxidation, and in-situ bioremediation in addition to or instead of tradtional remedies such as excavation and pump and treat. Technologies may be adapted over time as remediation progresses. Remedy implementation often provides additional insight into the true nature and extent of subsurface contamination.

Adaptive Treatment Strategy Addresses Extensive DNAPL Contamination

CLU-IN Resources

EPA's CLU-IN website offers a range of resources to help characterize and remediate sites with DNAPL. The DNAPL "issue area" contains case studies, guidance documents, and technical reports prepared by EPA as well as other federal or state agencies. The issue area focuses on halogenated alkenes and multi-component wastes (e.g, coal tar and creosote), but will enventually be expanded to cover other DNAPLs. Visit the issue area at: http://cluin.org/issues/default.focus/ sec/Dense_Nonaqueous_Phase_ Liquids_(DNAPLs)/cat/Overview/.

The Oregon Department of Environmental Quality (OR DEQ) is working with a site owner to remediate a 47-acre operative manufacturing facility near Troutdale, OR, using a series of innovative technologies to address trichloroethene (TCE) in the unsaturated zone and ground water. Initial cleanup efforts focused on pump and treat (P&T) with air stripping and subsequent installation of an interception trench (French drain) with air stripping to treat the upper gravel aquifer. Since the 1989 issuance of the record of decision (ROD), several additional remedies have begun operating: dual-phase extraction, soil vapor extraction (SVE), air sparging, phytoremediation, biostimulation, and a bioremediation barrier wall.

Cascade Corporation has manufactured forklifts at the site since 1956. Activities over the years have included product painting, parts and hydraulic cylinders assembly, nickel and chrome electroplating, vapor degreasing, and mechanical maintenance. Spent TCE was discharged to the ground, resulting in DNAPL source zones at locations now covered by the expanded facility. In addition, sludge from the degreaser tank and cutting oils containing TCE were disposed near a former underground storage tank (UST) and the edge of a parking lot that was subsequently expanded. As a result, separate TCE plumes formed beneath the manufacturing building and paved parking lot.

Near the former UST, LNAPL was detected in 1995 in two monitoring wells. Analyses of the LNAPL revealed TCE concentrations of up to 26,000 parts per million (ppm). The LNAPL serves as a long-term source of dissolved-phase volatile organic compound (VOC) contaminants and petroleum constituents in ground water, including downgradient private wells.

The site is immediately underlain by a 15-foot deposit of unconsolidated gravel with silt, sand, and clay. The underlying Troutdale Gravel Aquifer is a 50-foot-thick unconsolidated deposit of silty/sandy gravel with cobbles and boulders that transitions to an indurated sandstone at variable depths. A 15- to 50-foot-thick leaky aquitard separates the Trout Gravel Aquifer from the underlying Troutdale Sandstone Aquifer. Ground water in the Troutdale Gravel Aquifer is shallow and discharges in the form of springs at an erosional face.

Installed in 1998, a 21-well SVE system continues to remove VOCs from the unsaturated zone with assistance from capping provided by the existing building and paved parking lot. The system was augmented with a dual-phase extraction system to remove the LNAPL and air sparging wells to strip high-concentration VOCs from source-area ground water. The air sparging system was found to contribute minimally to contaminant removal, and thus was terminated the following year. The entire SVE system was shut down months later due to asymptotic recovery rates but restarted the following summer using pulse pumping. Activated carbon is used to treat offgases.

To enhance biodegradation of contaminants in the sub-building source zone, full-scale biostimulation was conducted in mid 2006. More than 82,509 gallons of an emulsified oil/water solution were administered in one area of the subsurface, and a sodium lactate solution in another area. The solutions were injected at locations immediately outside the manufacturing building, without disruption to ongoing activities. Two additional biostimulation events were planned, but only one was necessary to sufficiently reduce VOC concentrations.

Aggressive treatment of the source zone resulted in contaminant concentrations sufficiently lowered to allow implementation of less costly passive technologies. In 2006, the ground-water interception trench was expanded by 80 feet and converted to a mulch biobarrier. The biobarrier was added to the treatment train due to its low operation and maintenance cost and ability to augment P&T operations addressing the sand/gravel aquifer's high volume of water. Since barrier startup, P&T costs have decreased and ground-water flow to the springs has increased. The maximum TCE concentration in the springs last fall was 2.6 µg/L, which is below the cleanup target.

Phytoremediation is employed as a polishing step for residual contamination in the portion of the Troutdale Gravel Aquifer located between the biobarrier and the springs. In 1998, approximately 800 poplar trees were planted downgradient of the interceptor trench but upgradient of the springs. The trees were planted in a configuration sufficiently long to provide a root zone capable of capturing ground water (Figure 1).

Average TCE concentrations measured in 2006 near onsite source areas had decreased 22-61% over the previous year. The aggressive steps taken to biostimulate contaminant degradation in the sub-building source area resulted in reduction of TCE concentrations to an average below the 5 µg/L cleanup goal. At locations between the biobarrier and onsite P&T wells, ground water concentrations of TCE have decreased to an average of 5.2 µg/L. As a result, the OR DEQ is initiating steps to confirm that the cleanup goal is met for all target areas.

Contributed by Mavis Kent, OR DEQ (kent.mavis.d@deq.state.or.us or 503-229-5071)

Sodium Persulfate and Hydrogen Peroxide Injections Achieve Ground-Water Cleanup

The California Regional Water Quality Control Board (RWQCB), Los Angeles Region, oversees remediation of a 2.8-acre area known as the "Former Sta-Lube" site in Rancho Dominquez, CA. Cleanup technologies employed at this site since 1997 include SVE, P&T, and soil excavation with offsite disposal. In 2005, another excavation and addition of in-situ chemical oxidation (ISCO) quickly addressed a previously unknown DNAPL zone serving as a continued source of dissolved contamination.

Industrial activities at the site from 1968 until 1986 included the manufacture of paint, varnish remover, fuel additives, degreasers, and petroleum-based lubricants. Site investigations indicated VOC-contaminated soil and ground water, with methylene chloride as the primary chemical of concern. Leakage of methylene chloride from a former UST resulted in a dissolved plume estimated at 200 feet long and 80 feet wide as of 1995. Ten years later, the plume had shrunk to 80 by 30 feet, most of which was located under the remaining building, which continues to operate for administrative purposes. The maximum concentration of methylene chloride detected in ground water was 3,000 mg/L.

The site is located within the Central Groundwater Basin, which is part of the Los Angeles Coastal Plain. Near-surface sediment comprises primarily fine-grained silt and clay to a depth of approximately 45 feet below ground surface (bgs). Ground water is encountered at approximately 40 feet bgs. The upper aquifer extends approximately 140 feet bgs, and is separated from a lower (450-700 feet bgs) aquifer by several clay-lens aquitards. The aquitards limit vertical migration of contaminants to the lower aquifer, a high-quality drinking water source.

A P&T system operated from 1997 until 2003 to treat the dissolved-phase ground-water plume. From early 2000 until late 2001, an SVE system supplemented with hot-air injections treated vadose-zone soil. Concentrations of methylene chloride in pumping wells had decreased to below 100 µg/L, and both soil and ground water nearly attained closure from the RWQCB. However, concentrations rebounded significantly, suggesting DNAPL presence. Hence, operation of each system was suspended.

Results of a membrane interface probe survey indicated that methylene chloride DNAPL was trapped in sandy stringers in a clay zone located 40-48 feet below the building. To remove DNAPL, the area was excavated in 2003 to a depth of 48 feet using large-diameter augers. More than 266 yd³ were excavated and disposed offsite.

The Los Angeles RWQCB's efforts to accelerate dissolved-phase cleanup were initiated in 2005 after soil excavation/disposal and six years of SVE and P&T operations. The primary cleanup goal set at that time was attainment of methylene chloride concentrations below 50 µg/L in ground water. Based on the results of a more detailed site investigation identifying additional DNAPL directly below the facility's building, ISCO was selected as a remedy enhancement.

A total of 23 ISCO injection wells were installed at the site, of which 16 were placed inside the building and 7 outside the building, each with an estimated 8- to 12-foot radius of influence. Approximately 7,700 gallons of 22% sodium persulfate solution were injected over six days in mid 2005, followed by injection of 12,044 gallons of 17.5% hydrogen peroxide over 14 days to activate the persulfate. Downhole thermocouples monitored subsurface temperature to ensure a temperature of 120-160°F for optimum generation of hydroxyl radicals with minimal decomposition of the hydrogen peroxide. Logistical challenges include using angled wells to minimize disruption of business operations and operating the wells safely within the building. Injection flows were optimized to control the reactions and to minimize the potential for treated ground water and vapor to migrate to the ground surface through existing soil crevices. An additional 16 injection wells surrounding the 23 chemical injection wells were used for hydraulic control by injecting (dripping) tap water to prevent outward migration of the injected chemicals. Two vapor control/extraction wells were also installed and operated during the chemical oxidation to prevent vapor migration into the industrial/warehouse building.

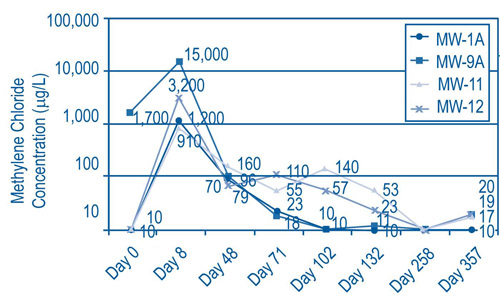

ISCO application resulted in 94-97% reduction in methylene chloride concentrations within four months, and to concentrations below the 50 µg/L cleanup goal within five months (Figure 2). In particular, one well experienced a concentration decrease from 15,000 to 18 µg/L. Most recent results of quarterly monitoring indicate that methylene chloride concentrations are below 33 µg/L. Accordingly, the Los Angeles RWQCB has initiated closure of the Former Sta-Lube site.

Contributed by Gary Cronk, Jag Consulting Group, Inc. (gary@jagconsultinggroup.com or 714-241-7722), Pinaki Guha-Niyogi, California EPA (pguha@waterboards.ca.gov or 213-576-6731) and Mehmet Pehlivan, Leighton Consulting, Inc. (mpehlivan@leightongroup.com or 949-250-1421 ext. 4264)

Integrated Technology Approach Used to Remediate Site Contaminated by 56 Chemicals

EPA Region 9 is using several technologies to treat soil and ground water at the Pemaco Superfund site in Maywood, CA. Cleanup began in 2005 with placement of a conventional soil cover over the entire 1.14-acre site to establish plant growth and stabilize soil. Full-scale treatment began last summer through use of a P&T system containing granular activated carbon (GAC), and startup of an electrical resistance heating (ERH) system shortly thereafter to vaporize VOC hotspots. A portion of the integrated system's high electricity demand is met through solar energy. Intermediate results as the remedy progresses indicate that ground-water concentrations have been reduced significantly and are on a downward trend. Air emissions have met standards throughout remedy implementation.

The site is located on the grounds of a former chemical mixing facility in a light industrial and residential area. Following 1991 closure, a fire destroyed the facility in 1993 and emergency actions were taken to remove the remaining 10,000- to 20,000-gallon chemical and fuel storage containers. Removal actions included offsite disposal or recycling of six 55-gallon drums, several above-ground storage tanks, and 31 USTs.

Subsequent site assessment indicated past releases of 56 chemicals including aromatic solvents, flammable liquids, oils, specialty chemicals, and metals. The largest contaminant plume, approximately 1,300 feet long and 750 feet wide, occurs in a lower aquifer situated 80-100 feet bgs. The plume consists almost entirely of TCE and its degradation products. Maximum TCE concentrations were 3,300 µg/kg in the upper vadose zone (2-30 feet bgs), 2,100 µg/kg in the lower vadose zone (35-65 feet bgs), 680 µg/L in perched water (20-40 feet bgs), and 22,000 µg/L in the aquifer. Investigations also revealed LNAPL consisting of 20-30% gasoline-range hydrocarbons.

An initial SVE system was installed in early 1998 to treat contaminated soil in the former UST area. The system comprised 16 extraction wells, a pre-treatment GAC filter system, and a portable thermal oxidizer operating at temperatures exceeding 1,400°F. During incineration, most contaminants were reduced to byproducts such as carbon dioxide and water. The system treated 72 tons of contaminated soil, removing 68 tons of contaminants. Due to insufficient data on potential dioxin emissions from the thermal oxidizer and related community concerns, the SVE system was shut down after 16 months of operation.

Selection of the final cleanup remedy, as formalized in a 2005 ROD, involved determination that remediation goals could be met through a strategy combining several technologies. The strategy includes enhancement to the initial SVE system and additional means to address contaminant hotspots. Target zones and treatment technologies now include:

- Surface and near-surface soil: Enhanced revegetation of the soil cover,

- Upper vadose soil and perched ground water: A high-vacuum dual-phase extraction system using GAC for water, and a high-temperature flameless thermal oxidation (FTO) unit and GAC for vapor treatment, and

- Lower vadose soil and exposition ground water: An ERH system to treat approximately 30,000 yd³ of soil at a depth of 35-95 ft bgs; vapor extraction and subsequent GAC and FTO treatment; vacuum-enhanced P&T employing GAC; and monitored natural attenuation (MNA).

The full-scale system includes 89 vapor extraction wells, 58 ERH electrode wells, and 30 thermocouple wells. The selected FTO is capable of heating contaminated vapor to temperatures of 1,400-1,700°F.

Prior to startup, a vapor conditioning package that includes a heat exchanger and additional GAC adsorption units was installed to the post-exhaust side of the FTO unit to minimize possibility of dioxin release. The final monitoring plan also calls for enhanced indoor and neighborhood ambient-air monitoring as well as direct sampling of FTO emissions, including dioxin and furan concentrations.

For ground-water and soil-vapor treatment, 20 two-phase extraction wells with high-vacuum pumps were installed in an area of the plume with TCE concentrations of 1,000-10,000 µg/L. An additional fifteen extraction wells were installed along the leading edge of the plume (with TCE concentrations greater than 10 µg/L but less than 1,000 µg/L) for contaminant containment. MNA is used to evaluate portions of the leading edge with TCE concentrations at or below 10 µg/L.

Construction of the underground conveyance piping, ground-water extraction wells, and vapor extraction wells was coordinated with the City of Maywood’s development of infrastructure for a riverfront park. The entire treatment system, including the aboveground treatment plant, was completed within one year. Incremental operational startup began with April 2007 commencement of the ground-water system, followed by the vapor-treatment system the following month and the ERH system another three months later. Sodium lactate was injected directly into the ground-water plume during the startup phase to stimulate in-situ bioremediation.

As part of Region 9's Cleanup-Clean Air Initiative, a 3-kW photovoltaic system was installed on the roof of the treatment building last year to meet part of the treatment system's electricity demand. The system generates approximately 375 kWh of electricity each month, preventing an estimated carbon dioxide emission totaling 4,311 pounds each year. After nine months of operation, the system generated enough electricity to pay for one month of operating the treatment plant. At this payback rate, capital cost of the solar system will be recovered in one year.

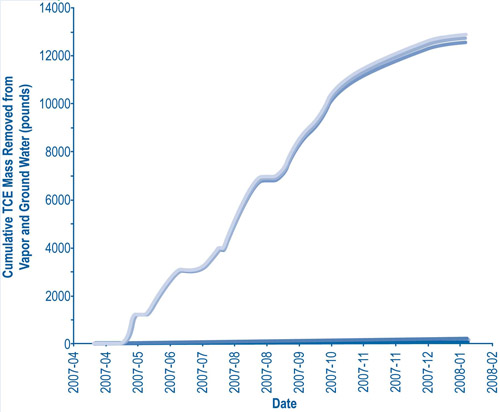

After approximately 120 days of ERH operation, temperatures in the source zone averaged 208°F. Cumulative electricity consumption of the ERH system approached 3.35 MkWh, or 111.7 kWh per cubic yard of treated soil. In early February of this year, performance monitoring indicated a vapor-mass removal rate of 0.32 lb/day at a vapor extraction rate averaging 504 ft³/min (Figure 3). TCE concentrations of P&T influent averaged 320 µg/L, while effluent concentrations averaged 1 µg/L. TCE mass removal from ground water averaged 0.12 lb/day.

Pemaco cleanup is expected to cost approximately $17 million, including more than $3 million for site assessment. Operation of the ERH system, estimated to cost $67/yd³, is expected to continue until this spring. The city has nearly completed construction of the Maywood Riverfront Park, which will become part of the Los Angeles River Greenway.

Contributed by Rose Marie Caraway, EPA Region 9 (caraway.rosemarie@epa.gov or 415-972-3158).

EPA's Technology Innovation and Field Services Division (TIFSD) and the University of Massachusetts-Amherst's Environmental Institute will jointly sponsor Triad Investigations: New Approaches and Innovative Strategies on June 10-12, 2008, in Amherst, MA. Best practices and lessons learned will be woven together throughout the conference to help participants use the Triad approach for improved decision-making regarding hazardous site characterization, remediation, and redevelopment. The conference includes 54 platform presentations, technical posters, equipment demonstrations, and specialized Triad training sessions with opportunity for continuing education credits.

EPA's Technology Innovation and Field Services Division (TIFSD) and the University of Massachusetts-Amherst's Environmental Institute will jointly sponsor Triad Investigations: New Approaches and Innovative Strategies on June 10-12, 2008, in Amherst, MA. Best practices and lessons learned will be woven together throughout the conference to help participants use the Triad approach for improved decision-making regarding hazardous site characterization, remediation, and redevelopment. The conference includes 54 platform presentations, technical posters, equipment demonstrations, and specialized Triad training sessions with opportunity for continuing education credits.

Workshops will address:

- Anatomy of a well-structured project,

- Best practices for efficient soil-sampling designs,

- Use of 3-D and 4-D site characterization and visualization techniques,

- Flux-based site management, and

- Spatial Analysis and Decision Assistance (SADA) tools.

Advanced training also will cover design application and data analysis for field-portable X-ray fluorescence and characterization, and long-term management of contaminated ground-water plumes.

An interactive "tool room" will be available for hands-on use of new automated systems for data collection, continuous monitoring, and long-term monitoring. Participants may use tools such as:

- Scribe configurable integration and migration software,

- SADA software for environmental assessment decision-making, and

- Rapid Assessment Tools Software (RATS) for real-time field mapping.

The exhibit hall will host nearly 30 booths offering analytical instrumentation, environmental software, monitoring tools, equipment for excavation or remediation, and related information or services. An outdoor courtyard also will host vendor demonstrations of equipment such as direct-push probes and samplers. Poster sessions will showcase site-specific strategies that have been used to apply Triad principles in remedial systems and to improve remedial performance through real-time feedback.

Conference content and activities are overseen by a scientific advisory board comprising representatives of both government and industry organizations. More information is available online at http://www.umass.edu/tei/conferences/triad.html; registration may be completed on Trainex (http://www.trainex.org).

Other major events co-sponsored by TIFSD this year include the:

International Environmental Nanotechnoloy Conference, October 7-9, 2008, in Chicago, IL, through partnership with the U.S. Department of Defense, U.S. Department of Energy, National Science Foundation, and additional federal agencies; http://emsus.com/nanotechconf/index.htm.

Remediation of Abandoned Mine Lands Conference, October 2-3, 2008, Denver, CO, in cooperation with the National Ground Water Association; http://www.ngwa.org/development/conferences/details/0810025019.aspx.