This issue of Technology News and Trends highlights projects involving optimization reviews undertaken by the U.S. Environmental Protection Agency (EPA) and partnering state agencies or site owners. Each project involved an optimization review performed by an independent organization and funded by EPA's Office of Superfund Remediation and Technology Innovation. The highlighted projects illustrate how optimization can be used to modify specific components of a treatment process or monitoring program in order to improve remedy effectiveness, reduce remedy implementation costs, and increase technical efficiencies. The highlighted projects focus on sites with operating remedies; however, EPA is now applying optimization to all phases of remediation, from remedial investigation to site completion. For more information, including results of optimization reviews for nearly 100 sites, visit the Remediation Optimization focus area of CLU-IN at: www.clu-in.org/optimization/.

Process Modifications to Improve Treatment of Acid Mine Drainage

TNT Going Paperless!

As part of the federal government's efforts to "go paperless," this publication has graduated to an e-newsletter available through e-mail subscription or by accessing CLU-IN's online archives. Bimonthly issues will now provide additional project tools, supplemental electronic links, and multimedia illustrations while continuing to feature detailed information about 3 or 4 site-specific projects. This April issue is the final printed issue; readers who have not yet converted from printed to e-mail subscriptions can do so online by visiting www.clu-in.org/newsletters, scrolling down to the list of "E-mail Newsletters" options, clicking on "Technology News and Trends," and entering their e-mail address.

The Colorado Department of Public Health and Environment (CDPHE) and EPA's Region 8 office are conducting remedial actions at the 400-square-mile watershed comprising the Central City/Clear Creek Superfund site. The Argo Tunnel Water Treatment Plant (Argo WTP), located in Idaho Springs, CO, is one component of this work. The Argo WTP treats acid mine drainage (AMD) discharging from two former mining tunnels as well as acidic, metals-laden groundwater from a nearby canyon. Engineering studies, field tests, and an optimization review were conducted in recent years to improve the plant's effectiveness and efficiency in treating the AMD.

The watershed receives drainage from areas of the Colorado Mineral Belt, which crosses several mining districts in Clear Creek and Gilpin Counties. Water entering the Argo WTP averages a pH of 2.8 and contains high concentrations of heavy metals, including approximately 140,000 micrograms per liter (µg/L) iron, 95,000 µg/L manganese, 50,000 µg/L zinc, 20,000 µg/L aluminum, and 5,000 µg/L copper. Water flows from the 4.16-mile Argo Tunnel, which supplies the majority of plant influent, at an average rate of 200-450 gallons per minute (gpm).

The plant began operating in 1998 with a treatment system that adjusts pH and removes metals through chemical precipitation. The fully treated water is discharged directly to Clear Creek, a tributary of the South Platte River. Design of the treatment process anticipated production of an underflow sludge containing 7% solids and dewatered filtercake containing 45% solids. Actual performance of the plant, however, has produced sludge with 3-4% solids and filtercake with 17-20% solids, resulting in significantly more filtercake needing disposal and increased labor costs. Each month, a total of approximately 385 cubic yards of filter cake is shipped via 24 18-cubic-yard roll-off containers to a municipal landfill for disposal. Filter cake disposal averages $150,000 per year, or about 15% of annual operating costs.

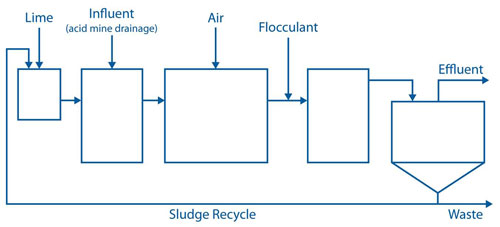

A 1999 engineering evaluation attributed the difference in design versus actual sludge and filtercake properties to the absence of a "true" high-density sludge (HDS) process. The Argo WTP process produces underflow solids that are recycled from the bottom of the clarifier back to the reactor (flocculation) tank. In a true HDS process, underflow solids are recycled from the bottom of the clarifier back to a sludge-conditioning tank (Figure 1) where the recycled solids mix with lime slurry. The mixture is then added to the influent to adjust pH. Conversion of the plant to an HDS process was estimated to cost $800,000 in 1999.

In anticipation of transferring project ownership and operation and maintenance (O&M) costs from EPA to CDPHE, an optimization review was conducted in 2007. Results of the review suggested modifying the reactor tank to increase solids recycling in a quasi-HDS manner, at an estimated cost of $75,000. The review also recommended adding aeration to the process, at an estimated cost of $60,000, in order to reduce the treatment pH. Most significant in terms of operating expenses, the review recommended installing new filter presses that would cost approximately $560,000. Additional recommendations involved improvements to the sand filter and the lime delivery system.

CDPHE proposed implementing a "true" HDS system rather than modifying the existing reactor tank with the intent of improving solids density and reducing chemical usage. While not specifically recommended by the optimization review, this approach is consistent with the intent of reducing ongoing costs related to sludge disposal, chemical usage, labor, and filter scaling. Of the funding provided by EPA through the optimization review process, $1,065,000 (including $695,000 for capital improvements to the solids handling system) directly apply to the alternate approach that was subsequently chosen.

Design of the new treatment process is nearly complete. Elements of the HDS process are based on the results of onsite pilot testing conducted over four weeks in November-December 2009. The tests focused on comparing two treatment trains that used different sludge solids recycle ratios. Because the plant influent contains a high amount of dissolved ferric iron, two small-scale reactors were used. The target pH level for precipitating ferric iron was 4.0, while the remaining metals were expected to precipitate at a pH of 9.0-9.5.

Test results indicated improved treatment of the process influent, with dissolved metal concentrations below target levels for iron (<15,800 µg/L), zinc (<225 µg/L), and copper (<17 µg/L). Dissolved cadmium was non-detectable at a reporting limit of 5 µg/L and both dissolved and total recoverable lead concentrations were non-detectable at a reporting limit of 5 µg/L. Total recoverable metal concentrations of cadmium, zinc, and copper remained above target limits but are expected to reach effluent goals under full-scale conditions that include a properly sized clarifier for settling and post-clarification filtration. Mixed results were achieved for manganese, the most challenging metal under this treatment process. Dissolved and total recoverable concentrations for manganese also would be expected to reach target levels through a full-scale system with more efficient aeration that results in better oxidation.

The process conversion will require new sludge-conditioning tanks, aeration blowers, sludge pumping systems and piping, and electrical supply and controls. The clarifier tanks currently in use will be converted to HDS reactors. Most significantly, a new 50-foot-diameter clarifier/thickener will be constructed outside of the primary treatment building. Since the plant uses a dual treatment train, one train can be converted while the other continues to operate and plant shutdown will be unnecessary.

Full-scale HDS application is expected to result in an 89% reduction in wet sludge volume per unit mass of dry solids. The process also is expected to reduce the volume of dewatered sludge by approximately 75% and reduce the dewatering time by approximately 95%. These reductions will lead to lower costs for labor, power, and transportation and disposal associated with sludge wasting, dewatering, and management.

CDPHE anticipates construction to begin in summer 2012. The cost to pilot test and design the process modification totals approximately $550,000, and construction costs for the modified system are estimated at $2,500,000. Annual O&M costs are expected to decrease by approximately $200,000.

Contributed by Mary Boardman, CDPHE, (mary.boardman@state.co.us or 303-692-3413) and Mike Holmes, EPA Region 8 (holmes.michael@epa.gov or 303-312-6607)

Combined Remedy Optimization at Superfund Site Saves Over $400,000 Annually

EPA Region 9's Superfund Office is optimizing the remediation technologies used to clean up soil and groundwater at the Pemaco Superfund site in Maywood, CA. Due to significant contaminant reductions since treatment began in 2007, an optimization review was conducted in January 2011 to identify opportunities for modifying or potentially downsizing certain components of the remedy. The recommended optimization approach has led to a decrease in the pumping rate and associated energy consumption of the pump and treat (P&:T) and soil vapor extraction (SVE) systems, focused vapor recovery, reduced sampling efforts across the site, and significantly decreased annual O&:M costs.

A chemical blending and distribution facility operated at this 1.4-acre site from the late 1940s until June 1991. A wide variety of chemicals, including aromatic and chlorinated solvents, flammable liquids, specialty chemicals, and oils, were stored in a combination of aboveground storage tanks, underground storage tanks, and drums. During the initial site assessment in 1997, EPA found 56 contaminants in surface and near-surface soil (0 to 3 feet bgs), the upper vadose zone soil and perched groundwater (3 to 35 feet bgs), the lower vadose zone soil (35 to 65 feet bgs), and the saturated zone (65 to 175 feet bgs). High levels of volatile organic compounds (VOCs), as well as metals and semivolatile organic compounds were detected. The largest contaminant plume in the saturated zone consisted primarily of trichlorethene (TCE) and its degradation products and was about 1,300 feet long by 750 feet wide.

The 2005 record of decision (ROD) selected a combined remedy to treat each of the three contaminated zones. Soil capping and limited hot spot removal were chosen for surface and near-surface soil, high-vacuum dual-phase extraction (HVDPE) was chosen for upper vadose zone soil and perched groundwater, while electrical resistance heating (ERH) with SVE, as well as vacuum-enhanced groundwater extraction, P&T, and monitored natural attenuation were chosen for areas of highest contamination in lower vadose zone soil and the saturated zone. An onsite treatment plant was constructed to treat extracted soil vapors and groundwater with granular activated carbon (GAC). A flameless thermal oxidizer (FTO) was also used to treat vapors when the thermal treatment system was operational. The combined remedy began operating by 2007.

The ERH was activated in the source area for 200 days. The FTO was turned off during the summer of 2008, but the additional components of the remedy still operate.

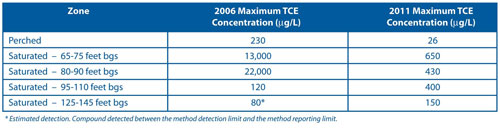

Significant decreases in VOCs, such as TCE, have been observed since implementation of the remedy. Plume migration resulted in concentration increases of some contaminants in the deeper zones of the aquifer (Table 1) but are addressed in the optimization strategy.

Significant decreases in target contaminant concentrations in the perched and upper saturated zones of groundwater across the site offered an opportunity to modify remedial processes. Between July and November 2011, a series of steps were taken to optimize remedy efficiency, largely focusing on monitoring reduction due to decreased contaminant concentrations across the site. More than half (226 of 432) of the annual samples collected were eliminated from the monitoring program by reducing the number of monitoring wells and the frequency of sampling. Sampling was discontinued in wells where contaminant concentrations remained below the site-specific remediation levels (SSRLs) for four consecutive quarters. Monthly sampling was discontinued sitewide, and quarterly sampling was implemented in 15 wells with semi-annual sampling in 73 other wells. The overall reduction in monitoring frequency is estimated to decrease annual labor, analytical, and other direct costs by $230,000.

To help address contaminant migration in the deeper portions of the saturated zone, one monitoring well was converted to an extraction well to increase pumping at 100 — 105 feet bgs. A new monitoring well screened at 125 — 145 feet bgs is planned for installation by April 2012 in response to a newly discovered offsite upgradient source that affects the western portion of the site. Installation of the new well is expected to cost $37,500, while annual monitoring costs are estimated at $4,000.

The optimization review results also recommended reductions in the monthly sampling of water and vapor processed by the onsite treatment plant. The project team will reduce the number of process water samples from eight (taken from multiple lines) to one combined influent sample and one effluent sample, eliminating process sampling points from well headers and intermediate locations that do not influence system operation decisions. Optimization of the sampling strategy will lead to a reduction from 96 to 24 annual samples. The project team also will reduce sampling of vapor processed by the onsite treatment plant to one influent and one effluent sample per month, in contrast to the 12 vapor samples previously processed each month. Cost savings from reduced process water and vapor sampling are estimated at $54,000 annually.

Eight additional effluent samples from the onsite treatment plant are analyzed each year for sewer discharge pretreatment parameters as required by a Los Angeles County Sanitation District permit. This sampling program is not subject to modification until the facility begins discharging under the National Pollutant Discharge Elimination System, tentatively in April 2012.

Sitewide sampling of vapor and groundwater extraction wells in October 2011 confirmed that extraction is only needed from 16 of about 55 vapor extraction wells and 29 of about 57 groundwater extraction wells (including HVDPE wells); extraction wells exhibiting VOC concentrations below SSRLs were turned off. The terminated wells will be sampled for rebound during the next semi-annual sampling event (in April 2012) to confirm that vapor concentrations do not return to levels above applicable standards. The remaining active vapor extraction wells pump at a lower rate of 200 cubic feet per minute (cfm) rather than the previous rate of 500 cfm, while remaining active groundwater extraction wells pump at a lower rate of about 20 to 25 gpm rather than the previous rate of 31 gpm, due to optimization review findings that a lower pumping rate would result in the same amount of contaminant removal. Reducing the number and pumping rate of active extraction wells, including HVDPE, allows the two blowers to operate one at a time, which is expected to reduce annual electricity costs by approximately $40,000.

Due to reduced sampling, analysis, reporting, and maintenance requirements resulting from optimization of the treatment system, the full-time workforce has decreased from three to two plant personnel and one "as-needed" staff member. This reduction reduces annual labor costs by approximately $113,000. The total annual cost savings corresponding to monitoring reduction, elimination of several dozen vapor and groundwater extraction wells, reduction in groundwater and vapor pumping rate, conversion to an alternating blower system, and reduction in personnel costs is estimated at $437,000.

The site team will be conducting additional work to identify the origin of the offsite upgradient source that is impacting cleanup at the site, as indicated by recent sampling results.

Contributed by Rose Marie Caraway (caraway.rosemarie@epa.gov or 415-972-3158) and Lynn Suer (suer.lynn@epa.gov or 415-972-3148), EPA Region 9

DNAPL Discovery Affects Groundwater Treatment and Anticipated Site Reuse

EPA's Region 10 office has conducted soil and groundwater cleanup activities at the Northwest Pipe and Casing/Hall Processing (NWPC) site in Clackamas, OR, since its addition to the National Priorities List in 1992. Efforts are underway to improve efficacy of groundwater treatment while accommodating ongoing and future redevelopment of the site. The State of Oregon is in the final phase of designing a major six-lane highway and surface street enhancements that will completely transect the site. Additionally, Clackamas County, the current owner of half the site, has leased a large parcel to a steel fabrication and manufacturing facility for storage use and street car testing.

The NWPC site is located in an industrial area approximately 20 miles southeast of Portland. It encompasses approximately 53 acres divided into two parcels. One 32-acre parcel is the main area of concern due to high concentrations of VOCs in soil and groundwater that corresponded with past use of cleaning solvents in pipe-coating operations. A remedial investigation completed in 2004 detected TCE in 53 out of 78 groundwater samples, at concentrations ranging from 0.2 to 1,900 µg/L. Cis-1,2-dichloroethene (DCE) was detected in 59 out of 78 samples at levels of 0.4 to 3,000 µg/L. Vinyl chloride detections in 44 out of 84 samples, at concentrations ranging from 0.6 to 340 µg/L, suggested that biological reductive chlorination of TCE and DCE was occurring gradually. Dense non-aqueous phase liquid (DNAPL) was not observed during the remedial investigation.

Soil remediation primarily involved excavation and capping in 2001-2003. Construction of the groundwater remedy, completed in 2004, involved use of an in-well air stripping system consisting of 15 groundwater circulation wells connected to six extraction sheds, each of which housed a blower, vapor extraction equipment, and GAC treatment canisters. Within a year of startup, monitoring indicated that the system did not function as designed. Follow-up field studies suggested that the groundwater circulation system primarily recirculated treated water and recovered very little contaminated water from the aquifer. In the following year, eight wells were shut down and their down-hole equipment was removed.

An optimization review was conducted in 2007 to evaluate current performance of the remedy, determine the need to shut down remaining wells, and identify potential remedy alternatives. The optimization review report made three primary recommendations: (1) better define the upgradient boundary of the plume to facilitate future remedy decisions; (2) shut down the remainder of the groundwater treatment system, and (3) consider integrating alternate approaches such as in situ bioremediation or chemical oxidation to aggressively treat areas with the highest VOC concentrations. As a result, EPA completed a focused field investigation that involved collecting additional soil and groundwater samples using rotosonic drilling at 29 locations. The samples were collected over six weeks and analyzed at offsite laboratories for a cost of approximately $160,000.

Analytical results showed that a significant source of soil contamination was upgradient and aligned with the centerline of the main contaminant plume. More specifically, soil data indicated three coal tar body (DNAPL) sources. Results from depth-discrete groundwater sampling indicated high concentrations of chlorinated VOCs (CVOCs) and naphthalene encompassing or extending from those DNAPL bodies along the direction of groundwater flow. Concentrations of chemicals of concern in the three water-bearing zones (WBZs) also corresponded to the discovery of DNAPL. PCE, TCE, cis-1,2-DCE, and naphthalene concentrations greater than 1,000 µg/L were observed within or downgradient of the DNAPL bodies in the shallow and intermediate WBZs. In the deep WBZ, groundwater samples showed lower CVOCs, naphthalene, and BTEX concentrations. A limited number of deep WBZ samples indicated PCE and naphthalene concentrations exceeding 1,000 µg/L.

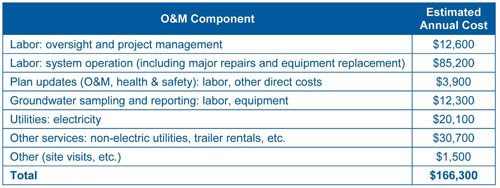

EPA terminated the groundwater treatment system shortly after the optimization review, approximately five years sooner than originally anticipated. The shutdown saved an estimated $166,300 each year in O&M costs (Table 2). Well decommissioning was postponed until 2015 to assure that wells or ancillary equipment are not needed for other remediation activities. Decommissioning costs for the entire groundwater treatment system are estimated at $350,000.

EPA completed a time-critical removal action in October 2009 through June 2010 to remove the coal tar bodies. The majority of excavation occurred near groundwater with the highest PCE concentrations, in an area approximately 80 feet long, 24 feet wide, and 25 feet deep. To address a nearby but relatively isolated source area, an interceptor trench was excavated perpendicular to the direction of groundwater flow and tied in to the larger excavation area at its downgradient edge. The excavated soil was dewatered and transported to an offsite Subtitle D disposal facility; prior to disposal, laboratory analysis of five-point composite samples of the dewatered material showed concentrations below the disposal thresholds.

Excavated areas were backfilled with sand, gravel, and existing overburden and cap material, where appropriate. To address residual soil contaminants entering the groundwater from (or downgradient of) the excavated areas, EPA implemented in situ bioremediation that would promote reducing groundwater conditions and provide a source of organic carbon for indigenous microorganisms. In the majority of excavation bays, a zerovalent, iron-organic carbon soil amendment was dug into the base and dosed into the backfill at either 0.6% or 1% concentrations, depending on the prevailing contaminant concentrations in groundwater. The walls of remaining seven bays were dosed with an amendment made from the chitin of crab shells.

Monitoring over the past two years indicates significantly decreased residual VOC concentrations in the immediate vicinity of the soil removal areas. For example, PCE concentrations in aqueous fractions of one representative well decreased from 2,570 µg/L to a non-detect level. Dechlorination and biological indicators observed over a longer period (since 2008) indicate that microbiological activity and resultant dechlorination increased significantly in the same areas after introduction of the soil amendments. The indicators included increasing concentrations of dissolved iron and methane and decreasing redox potential and sulfate concentrations. Late 2011 monitoring results showed reversed trends, which indicated that microbial activity had begun declining.

Other optimization review recommend-ations involved technical changes to the sequencing of data collection on site-wide water levels. Historically, this process was performed over a two-day period in which data were first collected for all shallow wells, then for intermediate wells, and lastly for deeper wells. Since 2007, all wells in the same vicinity have been sampled at the same time (regardless of depth) on a single day. This sequencing yields more accurate information regarding vertical head differences and horizontal water levels using several wells with multiple screen depths. Due to no change in the total number of labor hours, this improvement occurred without additional costs; site-wide water level data is typically collected every six months, at a cost of less than $5,000.

FRTR Discussions on Optimization

At its November 2011 meeting, the Federal Remediation Technologies Roundtable (FRTR) discussed aspects of federal efforts to optimize site cleanup remedies. Topics included performance-based contracting, environmental footprint reductions, and exit strategies. To access the meeting presentations, visit the FRTR online at: www.frtr.gov/meetings1.htm.

EPA's Region 10 office is currently conducting a focused feasibility study to augment the existing groundwater remedy. Technology alternatives include in situ bioremediation, as recommended in the optimization review report, combined with natural attenuation or an ex situ pump-and-treat system to treat the contaminant plume more aggressively.

Contributed by Mark Ader (ader.mark@epa.gov or 206-553-1849) and Bernie Zavala (zavala.bernie@epa.gov or 206-553-1849), EPA Region 10