This issue of Technology News and Trends highlights methods for harnessing energy from renewable resources to reduce remediation costs and minimize the environmental footprint left by remediation technologies. These methods currently are used to generate virtually no-cost electrical power for low-energy remediation systems, to "polish" remediation following aggressive baseline technologies, or to serve as baseline technologies addressing moderate contaminant concentrations. Incorporation of renewable energy resources early in remediation planning can significantly reduce long-term cleanup costs and allows site managers to evaluate environmental tradeoffs of potential remedies.

Solar Power Recirculates Contaminated Ground Water in Low-Energy Bioreactor

CLU-IN Resources

Environmentally sustainable cleanup technologies commonly include phytoremediation, bioremediation, and monitored natural attenuation but increasingly involve modifications to conventional technologies relying on passive rather than active mechanisms. Information about other no- or low-energy remediation technologies is available in the U.S. EPA's "Technology Focus" on CLU-IN (http://cluin.org/techfocus/).

A pilot-scale recirculation bioreactor has operated at "Landfill 3" on Altus Air Force Base (AFB), OK, since late 2003 to address a hotspot of volatile organic compounds (VOCs) in ground water residing in fractured clay and weathered shale. A solar-powered pump operating in the system’s extraction/collection trench recirculates ground water through the 10,000-ft3 bioreactor and into the aquifer to generate high-carbon leachate and enhance VOC biodegradation. Since startup, the system has transferred approximately 1,300 m3/yr of organic carbon-enriched leachate from the bioreactor into the aquifer. Ground water recirculation through the bioreactor has achieved a 98% reduction in trichloroethene (TCE) concentrations within the bioreactor and a 90-97% reduction in plume toxicity in hotspot wells between the bioreactor cell and the extraction trench.

Prior to project startup, TCE concentrations in the hotspot were 19 mg/L, and the plume extended nearly 1,100 yds downgradient of the landfill. The bioreactor was constructed immediately upgradient of hotspot wells in a 30- by 30-ft excavation extending 11 feet below ground surface (bgs). During excavation, landfilled materials were removed and disposed offsite as non-hazardous waste. The cell was backfilled with a 1:1 mixture of sand and organic mulch consisting of municipally-obtained woody material and cotton-gin trash, an inexpensive and locally available byproduct of the cotton industry. At the top of the cell a ground-water distribution (irrigation) system operates between two layers of geotextile fabric. The entire cell is capped with two feet of soil and a native grass cover.

The bioreactor relies on recirculation of ground water from downgradient of the hotspot, which is located in the shallow aquifer 10-18 feet bgs. Ground water collected in a 2-ft-wide by 30-ft-long trench extending 18 feet bgs is recirculated through the bioreactor by a single solar-powered pump. Contaminant degradation is monitored through a network of 18 wells.

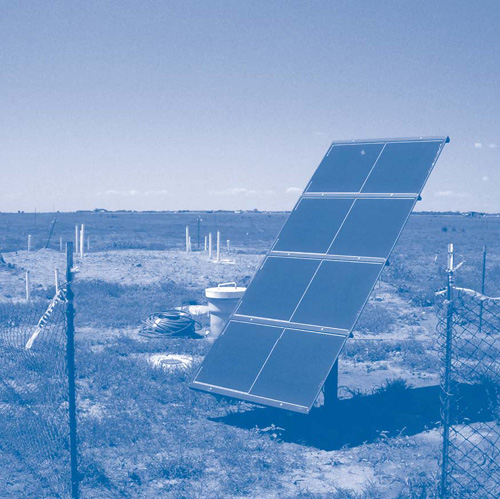

The site's remote location and average solar radiation of 4-5 kWh/m2/day prompted investigation of solar power early in the project planning process to reduce construction and energy costs associated with long-term pumping. The selected photovoltaic (PV) array comprises four single-crystal silicon panels, each capable of delivering 50 watts to the pump through a simple control box. The panels are mounted in series on a single frame oriented due south and angled for maximum sun exposure during winter months (Figure 1).

A 3-inch-diameter submersible pump, designed specifically for solar applications, is suspended in a sump installed in the extraction trench. The pump produces 2-3 gal/min during peak sunlight hours but does not operate overnight or during low sunlight, maintaining an average ground- water flow rate of 928 gal/day. Ground-water velocity between the bioreactor cell and the extraction trench likely increased from the estimated area-wide velocity of 0.1-1.2 ft/day due to hydraulic mounding in the bioreactor. In this case, downgradient water quality data suggest that some recirculated ground water may have bypassed the extraction trench, potentially due to the shallow depth and limited length of the trench and the intermittent, low-rate nature of pumping.

The solar unit, pump, and auxiliary equipment operated without breakdown and required little maintenance over three years of operation; the lifespan of the PV system is estimated at 20 to 30 years. Capital costs for the pump, controller, and PV array were low, totaling approximately $2,300. Energy cost savings achieved by the solar-powered system are estimated at less than $1,000/year but significantly higher savings were realized by avoiding construction of electric lines to connect to the local utility grid. Though no enhancements to the Altus PV system are required, its performance suggests that similar applications at other sites could easily increase PV capacity through use of a solar tracking device or larger PV array.

Evaluation of the bioreactor performance indicates dissolved organic carbon concentrations increased from less than 6 mg/L prior to startup to 120 mg/L in shallow wells and 30 mg/L in deeper wells. Increased concentrations of cis-1,2-dichloroethene, vinyl chloride, and ethene further indicate reductive dechlorination of TCE occurs in the bioreactor, and phospholipid fatty acid analysis shows a predominance of the anerobic bacteria required for this process. To achieve more complete reductive dechlorination of TCE, a semi-soluble carbon substrate and a bioaugmentation culture were added to the bioreactor last fall.

Results of the bioreactor's initial two-year demonstration, including details on the solar-powered pumping system, are documented in a final technical report to be released this summer from the Environmental Security Technology Certification Program (ESTCP) (http://www.estcp.org). The Air Force Center for Environmental Excellence (AFCEE) anticipates significantly increased use of solar as well as wind energy to power low-energy remediation systems such as bioreactors across the Department of Defense (DOD) complex, particularly in remote locations where utility-grid connection is cost prohibitive. Dyess AFB, an active base in Abilene, TX, recently converted the facility's entire operation to exclusive use of wind energy, and the Massachusetts Military Reservation is investigating the use of a 660-kW wind turbine to power the site's extensive ground-water cleanup program.

Contributed by Jim Gonzales, AFCEE (james.gonzales@brooks.af.mil or 210-535-4255), Roger Wilkson, Air Education and Training Command (roger.wilkson@randolph.af.mil), and Jason Bidgood, Parsons (jason.bidgood@parsons.com or 303-831-8100)

Wind Turbine Cost Study Shows Need for Redesigned Ground-Water Remediation Systems

University of Missouri-Rolla researchers recently evaluated the economic and environmental benefits of a 10-kW wind turbine powering a ground-water circulation well (GCW) at the former Nebraska Ordnance Plant (NOP) Superfund site in east-central Nebraska. The project's first phase involved retrofit installation and use of a grid inter-tie system whereby electricity is provided by the turbine during favorable weather. The local electric utility powers the turbine during unfavorable weather. Environmental benefits of the conversion included a potential reduction of greenhouse gases associated with fossil-fuel-generated electricity. When compared to utility-only operation, monthly emissions of carbon dioxide averaged 32% less during the grid inter-tie phase.

In late 2006, the second project phase converted the wind turbine system to off-grid operation powering the GCW submersible pump. Utility power was required for the remaining GCW components to meet energy demands during mid-winter low temperatures. Though estimated carbon dioxide emissions during off-grid operation were higher than those of the grid inter-tie phase due to cold weather, monthly emissions averaged 24% less than during utility-only operation.

The NOP site is located in an area with winds averaging 6.5 m/s, which the DOE considers suitable for wind turbine applications (Wind Energy Resource Atlas of the United States). The GCW submersible pump extracts contaminated water from the aquifer for above-ground air stripping to remove TCE. After treatment, ground water recharges the aquifer through a different well interval.

As part of this project, researchers evaluated the performance of the selected 10 kW-rated wind turbine as installed on a 30-meter tower. Electricity was delivered from the turbine to the GCW through a single circuit breaker, which eased the system's retrofit for power from an alternative energy source. The grid inter-tie system configuration resulted in monthly energy generation ranging from 500-1,000 kWh.

Although the same wind turbine was used for both study phases, an off-grid battery system was added for the second phase to store energy produced by the turbine. Production capacity of the grid inter-tie operating mode was rated at 7.5 kW, but was 25% lower for the off-grid mode due to reduced efficiency of the energy storage system. As a result, stored energy allowed the turbine to fully power only the 230-volt, three-phase submersible pump, which accounted for approximately one-third of the GCW's total demand. Additional modifications allowed the GCW to operate either through exclusive use of utility power or through intermittent use of the wind turbine to power the submersible pump, supplemented by utility power for remaining GCW components.

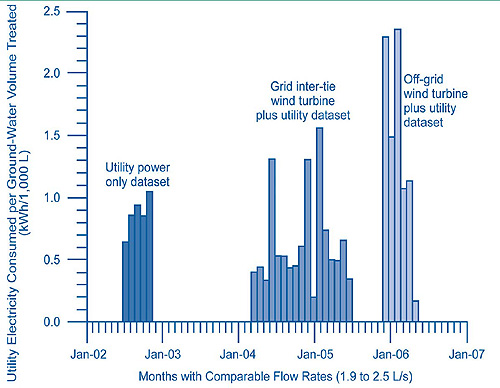

Economic benefits of the wind turbine were evaluated through several measures. Statistical comparisons were conducted on comparable data collected when the GCW relied on: (1) exclusively utility power, (2) combined utility and grid inter-tie wind power, or (3) combined utility power plus off-grid wind power or utility power alone (Figure 2). Results indicated that average daily energy consumption from utilities decreased 26% during the 17 months when the turbine operated in grid inter-tie mode. During two cold periods of the 6-month off-grid operation, the cost of heating the GCW to prevent freezing and associated decreases in submersible pump efficiency contributed to significantly higher demand for utility power.

Capital recovery was analyzed to evaluate whether NOP utility-cost reductions could offset wind turbine costs. Net capital costs were estimated at $41,000 for the inter-tie turbine system and $39,000 for the off-grid system, including turbine installation and utility connection. Based on a GCW rate of 5.7 million liters of ground water treated each month, the annual energy saved by the turbine in grid inter-tie mode was estimated at $1,100. Results suggested that less than 50% of the grid inter-tie system cost would be recovered over 20 years.

Net cost of the off-grid system, however, would be recovered in 14 years if the GCW were significantly modified to function without incurring any utility costs. System modifications would focus on freeze-proofing the GCW by automatically draining the system to accommodate intermittent operation during winter. Additional savings for an off-grid system would be achieved by using an alternate, low-energy treatment technology such as bioremediation.

A total TCE mass of 50.6 kg, averaging 2.99 kg/month, was removed through air stripping during the 17-month grid inter-tie operational phase. The average TCE mass removed during the six-month off-grid phase was 2.53 kg/month. Over both phases, a combined total of 90.2 million liters of ground water were treated without any net loss of ground water to the aquifer. The average reduction in carbon dioxide emissions during treatment was estimated at 437 kg/month during the grid inter-tie phase and 317 kg/month during the off-grid phase, as compared to a potential emission of 1,600 kg/month during utility-only operations.

Final results suggest that wind turbines can be used to reduce operation and maintenance (O&M) costs for long-term ground-water remediation systems such as pump-and-treat (P&T) while significantly reducing carbon dioxide emissions. Although the study indicates that retrofit of existing GCWs with a wind turbine system is not cost effective, it shows that an off-grid system may be cost-competitive for a new GCW specifically designed to operate without utility power. Results also illustrate the need for wind-turbine GCW designs to accommodate cold weather conditions.

Contributed by Curt Elmore, Ph.D., University of Missouri-Rolla (elmoreac@umr.edu or 573-341-6784) and Dave Drake, U.S. EPA Region 7 (drake.dave@epa.gov or 913-551-7626)

DOE Uses No/Low-Energy Approaches for Long-Term Remediation

The U.S. Department of Energy (DOE) increasingly uses passive soil vapor extraction (PSVE) and DOE laboratory developments, such as the MicroBlowerTM and "GeoSiphon™," to address sites requiring long-term treatment. Use of these no/low-energy technologies at the Savannah River Site (SRS) significantly reduced electricity and fossil-fuel energy consumption/costs and demonstrates their ability to reduce the footprints of remediation strategies on the environment.

PSVE, also known as barometric pumping, uses natural venting cycles between the atmosphere and subsurface to extract contaminants from soil. When atmospheric pressure at the ground surface is higher than subsurface soil gas pressure, air flows downward through wells into the subsurface. When pressure at the surface is lower than subsurface, air flows from the wells to the atmosphere. As a result, a vadose-zone well crossing these pressure differentials can remove gaseous-phase VOCs from the subsurface without use of a mechanical pump and associated power sources. Prior to atmospheric discharge, extracted vapors may require relatively low-cost treatment such as carbon adsorption. PSVE commonly is used to inject air into soil to stimulate bioremediation.

The SRS and Hanford Site currently use PSVE as a polishing technology to remove VOCs from permeable soil. At SRS, for example, 52 PSVE wells across three separate areas have operated over the past 10 years. Combined, these systems have removed nearly 1,000 lbs of tetrachloroethene (PCE) and 400 lbs of TCE. In addition, vapor concentrations and gas-plume footprints have decreased significantly. Although rates of contaminant mass removal are declining due to reduced concentrations of contaminants, the PSVE systems are expected to continue operating until soil cleanup targets are met. Results at both SRS and Hanford confirm that PSVE is best applied where target contaminants are in the unsaturated zone, and is most effective in coarse soil with high permeability or in soil layers separated from the atmosphere by a confining unit or by depth.

Savannah River National Laboratory (SRNL) researchers are investigating PSVE enhancements such as wind turbine-powered vacuum pumps to increase system efficiency and further reduce cleanup costs and environmental impacts of remediation. One of the simplest methods for increasing efficiency involves integration of a simple one-way check valve capable of interrupting airflow into PSVE wells when atmospheric pressures reverse. Direct attachment of a control valve such as the BaroBall™ to the well casing at ground surface permits extraction of contaminants during reduced barometric pressure, while eliminating undesirable dilution caused by reinjection of clean air during periods of high barometric pressure. This type of valve may be used in other applications to inject air and/or nutrients into the subsurface for enhanced bioremediation, to control or confine movement of a subsurface gas-phase plume in the vadose zone, or to passively transfer solar-heated, water-saturated air into the subsurface for enhanced volatilization.

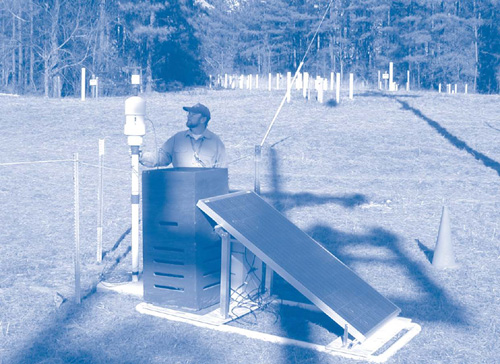

The MicroBlower™ is another no/low-energy technology used to remove VOCs from the subsurface. This system consists of a small 12- or 24-V DC vacuum blower connected directly to a wellhead for extracting or injecting gases into the vadose zone. PV panels or small wind generators typically supply electricity to power the system, enhancing its potential for use in remote locations. A battery bank can be used for reserve power when sun or wind is inadequate. Deployment is made easier by the system's small pump, approximately 4 inches high by 3 inches wide (Figure 3).

Ten MicroBlower systems currently operate at SRS, each removing 0.1 to several pounds of solvent from the subsurface each week. The cost of materials is estimated at $1,500 per system, with minimal installation and O&M expenses. Performance results indicate that reliability of a MicroBlower system depends on a pump lifespan of approximately one year.

Additional tests were conducted at SRS to evaluate the feasibility of GeoSiphon, a passive technology employing a siphon made of HDPE tubing to induce ground-water flow from the target portion of an aquifer toward a treatment cell. Once primed, the upward arm of the siphon draws water from the treatment cell, inducing ground-water flow towards the cell. The treatment cell consists of an 8-ft diameter well containing approximately 25 tons of granular cast iron that abiotically reduces chlorinated VOCs (CVOCs) to ethene, ethane, methane, and chloride ions. The downward arm discharges treated water to the Savannah River.

Three siphon configurations were tested using ½- to 2-inch HDPE tubing on engineered and non-engineered grades extending 223 to 1,032 feet on different slopes of the test site. All configurations on engineered grades maintained continuous, consistent siphon flow. When needed, an automatic, solar-powered vacuum pump was used for passively recharging the system's air chamber to remove gas bubbles.

The GeoSiphon shows potential for significantly improving implementation of permeable reactive barriers (PRBs) due to its ability to increase and direct the flow of water, resulting in less intrusive, less costly, and more efficient deployment compared to funnel-and-gate or continuous PRBs.

DOD has documented designs, costs, and/or performance results of natural pressure-driven passive bioventing at these DOE sites as well as DOD sites under the ESTCP (http://www.estcp.org). Both agencies anticipate additional remediation studies to investigate innovative methods for harnessing renewable energy from other natural resources such as ocean tide and geothermal forces.

Contributed by Brian Riha, SRNL (brian.riha@srnl.doe.gov or 803-725-5948) and Brian Looney, Ph.D., SRNL (brian02.looney@srnl.doe.gov or 803-725-3692)

Sustainability Metrics Used to Evaluate Remedial Actions

Savannah River National Laboratory (SRNL) researchers are developing tools to evaluate the need to power new or existing remediation systems with renewable energy sources. The tools employ sustainability metrics for assessing energy demand and storage along with characteristics of the site and contaminants. Early evaluation of these parameters can reduce the footprints of many aggressive cleanup technologies, which are now recognized increasingly as secondary impacts of environmental contamination. It can also help identify risk transfer across environmental media and associated regulatory programs.

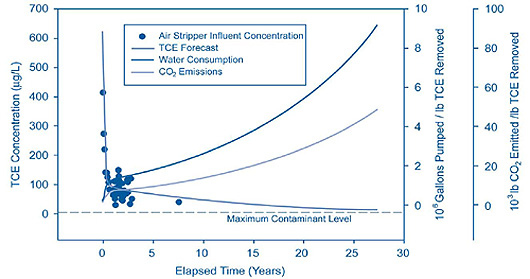

This strategy was demonstrated last year for a Savannah River Site (SRS) P&T system operating since 1996 to treat TCE-contaminated ground water. Following extraction, ground water is treated by a 70-gpm air stripping system and ultimately discharged to the Savannah River. Average TCE concentrations in treatment influent decreased from 600 µg/L to 40 µg/L after eight years of P&T operation. These dissolved CVOC concentrations (<50 µg/L or <0.0045 % solubility) mark the point at which media-specific benefits of baseline technologies such as P&T and in-situ chemical oxidation typically begin to be outweighed by increased burdens transferred to other environmental media, otherwise known as the onset of collateral environmental damage.

Common ground-water remediation goals such as hydraulic containment of contaminants, attainment of maximum contaminant levels, contaminant mass removal, risk reduction, and contaminant flux reduction do not reflect environmental burdens posed by cleanup technologies. Typical goals also do not reflect the value of in-situ environmental resource services such as drought buffering, prevention of land surface subsidence, protection against salt-water intrusion, and maintenance of ecological diversity. Accordingly, the SRNL study evaluated sustainability goals considered only minimally at the time of remedy selection:

- Resource conservation measured by "water intensity," or the amount of water necessary to remove one pound of contaminant,

- Energy efficiency measured by the amount of energy needed to remove one pound of contaminant, and

- "Carbon intensity" estimating the amount of CO2 emitted for each pound of contaminant treated, based on power industry standards.

During the first six months of air stripping operations, 100,000-500,000 gallons of ground water were removed for every pound of TCE removed. Influent contaminant concentrations over the following seven years were more moderate, decreasing from 100 µg/L to 40 µg/L. Water intensity during that period increased to 3,000,000 gallons per pound of contaminant removed. As of early 2006, TCE concentrations persisted at levels eight-fold higher than the 5 µg/L cleanup target.

Forecasts estimate that influent concentrations of TCE after 20 more years of P&T operation would still be 15 µg/L (three times the cleanup goal) and water intensity would increase to 9,000,000 gal/lb. The remediation system's carbon intensity also would increase exponentially to an estimated 50,000 lbs of CO2 for each pound of contaminant removed, significantly increasing the rate of risk transfer from ground water to the atmosphere (Figure 4).

Recent studies by the Interstate Technology and Regulatory Council, the National Research Council, and other government organizations recommend addressing the diminishing environmental returns of aggressive remediation technologies by:

- Evaluating collateral damages such as energy use and loss of environmental resources early in remediation planning,

- Establishing alternative metrics for tracking collateral impacts during active remediation, and

- Developing new economic models using sustainability metrics to balance natural resource damages with resource restoration.

SRNL will continue developing innovative strategies for minimizing collateral damage during remediation polishing. Potential methods involve harnessing new forms of renewable energy and leveraging prevalent site conditions with natural processes.

Contributed by Ralph Nichols, SRNL (ralph.nichols@srnl.doe.gov or 803-725-5228)