This issue of Technology News and Trends (TNT) provides selected updates on pilot projects and treatability studies described in past issues. Some technologies moved toward full-scale application at the study sites, while others were supplemented or replaced by one or more technologies, such as injections of vegetable oil or sodium lactate, soil mixing with zero valent iron, air sparging, and mulch reactive barriers.

Explosives Remediation at Pueblo Chemical Depot Changes Course

Online Resources

Thirteen years since its inception, CLU-IN now receives over 132,000 visits each month. To join more than 33,000 subscribers currently receiving "Tech Direct," CLU-IN's monthly announcements about new technical, policy, and guidance resources, visit www.cluin.org/newsletters/.

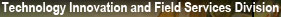

Treatment of soil and groundwater contaminated by energetic compounds has been underway since 1997 at area of interest (AOI) 3B of the Pueblo Chemical Depot (PCD) in Colorado. AOI 3B is part of the source of an explosives-contaminated groundwater plume. Initial work involved excavation and onsite composting of soil to address the contaminant source. In 2001, a pump and treat system using granular activated carbon and ion exchange began treating groundwater with high concentrations of RDX, 2,4-DNT, and nitrate near the PCD boundary. An electrolytic reactive barrier (e-barrier) subsequently was demonstrated at AOI 3B under the federal Environmental Security Technology Certification Program (ESTCP) to determine the technology’s efficacy in addressing remaining RDX and 2,4-DNT in source area groundwater. [For more information, see the September 2007 issue of TNT.]

Demonstration of the e-barrier concluded earlier this year. Samples collected after three years of operation indicated little reduction of RDX, TNT, and 2,4-DNT concentrations exiting the barrier and continued offsite migration of energetic compounds. Results suggested that e-barrier performance was limited due to wider distribution of the contaminant plume than originally estimated and its location directly above a thick shale aquitard. A complete cost and performance report will be available later this year from the ESTCP (www.estcp.org).

Remediation of the explosives plume is moving forward. PCD recently began implementing full-scale corrective measures involving enhanced in situ bioremediation (EISB) with a groundwater infiltration and recirculation system to stimulate microbial degradation of contaminants in the capillary fringe. EISB was selected based on successful application of the technology at similar sites and in PCD pilot studies.

Construction of the state-approved EISB system began with installation of two infiltration galleries within the floors of two previously excavated adjacent areas totaling 6,100 yd2. Each gallery consists of 3,100 linear feet of 1- and 2-inch perforated PVC pipe configured in a grid that will allow even distribution of amended water across the excavation area.

The EISB system includes seven injection and four downgradient extraction wells installed to depths of 10 to 20 feet (Figure 1). Well screens are positioned within the bottom two-thirds of the overall aquifer thickness. Flow rates from extraction wells are expected to range from 3 to 10 gpm.

Extracted groundwater will be amended with a solution of 0.5 to 2.0% sodium lactate and then reinjected into infiltration galleries or injection wells on a rotating schedule. In order to maintain reducing conditions in the aquifer, the solution will contain sufficient sodium lactate to maintain dissolved oxygen content below 1.0 mg/L. Pulsed injection will be conducted to allow flushing of the screen with recirculated groundwater between pulses, thereby minimizing biological growth on the screen and preventing associated biofouling.

The infiltration and injection recirculation system will be housed in a weatherproof enclosure and will consist of an influent tank, carbon substrate tank, pumps, sampling ports, and instrumentation with various fittings. The system will be built to recirculate groundwater via the injection pump or in a closed-loop mode with recirculation accomplished solely by the extraction well pump.

A nutrient solution containing carbon, nitrogen, and phosphorous in a 100:10:1 ratio also will be injected into the subsurface, either as part of the sodium lactate amendment or through separate events as warranted by groundwater nutrient conditions. The single set of extraction wells will maintain hydraulic control of sodium lactate solution as well as surface infiltration of carbon substrate solution.

Injection currently is scheduled to begin in July 2009 and continue for a minimum of 36 months. Recirculation and/or sodium lactate and nutrient addition may be extended or shortened following review of each quarterly monitoring event. Lactate recirculation will be considered complete and the system will be shut down when regulatory site-specific groundwater cleanup goals are met. During the post-recirculation stage, contaminants are expected to continue to degrade while groundwater moves under the regional gradient and additionally contacts accumulated explosives-degrading bacteria. Regulatory closure will be achieved once concentrations for contaminants of concern remain below specified cleanup levels at compliance points for three consecutive years after the remedy is complete. Cleanup requirements for RDX and 2,4-DNT are 0.825 µg/L and 0.1328 µg/L, respectively, based on risk-based groundwater cleanup levels specified by the State.

Contributed by Chris Pulskamp, PCD (christopher.pulskamp@us.army.mil or 719-549-4252), and Andrew Ellison, Shaw Group (andrew.ellison@shawgrp.com or 720-554-8167)

Five Additional Technologies Evaluated After ERH Application at Camp Lejeune

Groundwater at Site 89 of Marine Corps Base Camp Lejeune in North Carolina is contaminated with two dense non-aqueous phase liquid (DNAPL) plumes and a large dissolved plume. The Navy took a phased approach over the past six years to address each of these components. In 2003, electrical resistive heating (ERH) was evaluated in a pilot study to treat one DNAPL plume. In 2006, field-scale treatability studies were conducted to evaluate four technologies for treating the dissolved plume. In 2008, a removal action involving soil mixing with zero valent iron (ZVI) and clay was undertaken to treat the second DNAPL plume. Collective results and an upcoming feasibility study will be used to develop a record of decision by 2011.

ERH application used an array of 91 electrodes to deliver three-phase electricity in a 15,900-ft2, volatile organic compound (VOC) contaminated source area [see February 2006 TNT]. Six months of active subsurface heating at 100°C achieved a 97-99% reduction of VOC concentrations in groundwater and soil at the test area. The VOC bulk removal rate was as high as 440 lbs/day during peak performance, and a total of 48,000 pounds of VOCs was removed. At a unit cost of $137/yd3, ERH project costs totaled nearly $2.1 million for the total treatment volume of 15,311 yd3. ERH implementation at this site involved management of roughly 2,000,000 gallons of water from the interior of the treatment area, which was boiled off during the heating and collected for treatment and disposal.

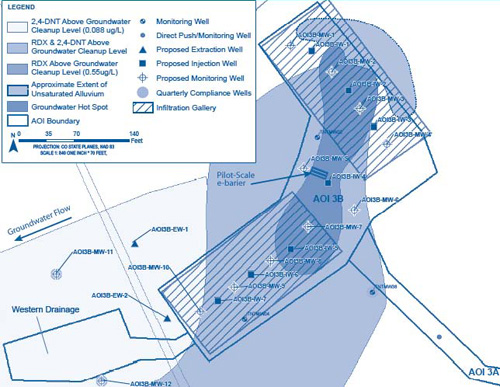

Subsequent treatability studies evaluated performance and design criteria of four additional technologies for addressing dissolved-phase contaminants: enhanced reductive dechlorination (ERD) by injecting emulsified vegetable oil (EVO) and sodium lactate, chemical reduction by way of ZVI injection using pneumatic fracturing, air sparging through a horizontal directional drilled (HDD) well, and a permeable reactive barrier (PRB) with mulch as a reactive medium. Each technology was evaluated on the basis of contaminant reductions and radius of influence (ROI). Study area selection was based on site layout, plume location, and avoidance of interaction among the four subareas. For example, the horizontal well was placed in an isolated elongated plume, and the PRB was constructed in the downgradient portion of the plume.

Field activities began with installing 11 new monitoring wells. Baseline samples were collected from new and existing wells in each subarea, and groundwater was monitored throughout the study. Highest baseline concentrations of predominant contaminants of concern in the study area were 21,000 µg/L for trichloroethene (TCE) and 14,000 µg/L for 1,1,2,2-tetrachloroethane (PCA). Results of the treatability studies for the dissolved-phase plume were as follows:

- ERD through EVO/Lactate Injection: Over one week, approximately 3,050 pounds of EVO and 3,300 pounds of sodium lactate were injected into the subsurface through four borings and chased with water (Figure 2). The injection depth interval was 10 to 25 ft below ground surface (bgs). Groundwater samples were collected from five monitoring wells one, three, and six months after the injection. Monitoring indicated a maximum 35-foot ROI surrounding each ERD injection location and an average TCE reduction from 333 to 8.7 µg/L. Analysis of field parameters, daughter products, natural attenuation indicator parameters, and microorganisms also suggested that reductive dechlorination had occurred.

- Chemical Reduction through ZVI Injection and Pneumatic Fracturing: Over one week, approximately 11,600 pounds of ZVI carried by nitrogen gas were injected into the subsurface through six borings with the aid of pneumatic fracturing. The injection interval was 12.5 feet to 25 feet bgs. Due to a high water table, pulsing was conducted to avoid daylighting of nitrogen gas to the surface near the injection point, which would significantly reduce the ROI. This approach inadequately fractured the formation and resulted in poor ZVI distribution across the target area. Sampling of five monitoring wells one, three, and six months after the injection showed no reduction in contaminant concentrations. Oxidation-reduction potential (ORP) declined over the monitoring period, indicating that subsurface conditions were slowly becoming favorable for reductive dechlorination.

- Air Sparging in HDD: Air was delivered through a 600-foot HDD sparge well with a 240-foot-long screen approximately 40 feet bgs near an existing building. The system was activated in December 2006 and operated continuously for approximately six months with an air compressor "up time" of 89%. After three months of air sparging, pneumatic fracturing was conducted in four borings spaced 50 feet apart along the axis of the horizontal well screen, at 3-foot intervals from 12.5 to 25 feet bgs. Monthly monitoring was conducted at eight groundwater monitoring wells and three soil vapor wells. Results indicated a 60-foot ROI from the sparge well, with little ROI enhancement from pneumatic fracturing. Average TCE concentrations decreased from 875 to 58 µg/L. Soil vapor concentrations increased during active sparging, but site-specific screening criteria (based on industrial exposure) were not exceeded.

- PRB with Mulch: A one-pass continuous trencher was used to construct a 210- by 2-foot trench to a depth of 25 feet, which intercepted groundwater flowing to an onsite creek at a rate of 0.14 ft/day. Approximately 200 yd3 of mulch from the base's recycling area and 480 yd3 of sand were placed in the trench to achieve a ratio of 40% mulch as a reactive medium and 60% sand as an aggregate. Groundwater monitoring included sampling at 11 monitoring wells one, three, and six months after PRB construction. Average TCE groundwater concentrations in the wall decreased from 13,573 to 442 µg/L. Study results indicated favorable conditions for contaminant degradation (low ORP, high total organic carbon, and low dissolved oxygen) but determination of PRB effectiveness over the six-month study was limited by slow groundwater flow.

Overall effectiveness of each technology was evaluated during the treatability study in terms of reducing concentrations of chlorinated VOCs within the surficial aquifer while balancing the technology's cost and implementation ease (Figure 3).

Soil mixing with ZVI and clay was used last year to treat the second DNAPL area. In this process, ZVI reacts with contaminants to destroy them, while the bentonite clay promotes uniform ZVI distribution during mixing and reduces hydraulic conductivity and associated contaminant migration. Source area contamination extends to approximately 25 feet bgs and encompasses 30,000 yd3 of soil containing an estimated 62,000 pounds of solvents. A total of 900 tons of ZVI and 1,082 tons of bentonite were mixed into 515 overlapping columns, while off-gas was collected and treated with activated carbon. Treatability tests indicated an optimum mix of 2% ZVI and 3% clay. The first round of quarterly monitoring indicated favorable results, with a 99.7% reduction of total VOCs in soil and 92% reduction of total VOCs in groundwater; both TCE and PCA concentrations decreased more than 99%. The unit cost for soil mixing was approximately $94/yd3, for a total treatment cost of $2.82 million.

The Navy anticipates moving forward with a site-wide feasibility study (FS) next year to focus on the dissolved groundwater plume. The FS will evaluate air sparging and ERD combined with monitored natural attenuation (MNA) and land use controls. Based on the treatability study results, air sparging with a horizontal well may be expanded to treat elevated VOC concentrations across the entire site. MNA will be relied upon to treat portions of the site where contaminant degradation is documented.

Contributed by David Cleland, NAVFAC Mid-Atlantic (david.t.cleland@navy.mil or 757-322-4851), Gena Townsend, EPA Region 4 (townsend.gena@epa.gov or 404-562-8638), and Chris Bozzini, CH2M Hill (chris.bozzini@ch2m.com or 704-544-5163)

Pilot Tests Lead to Full-Scale ISCO Using Sodium Permanganate in Fractured Bedrock

Two-phase pilot testing of in-situ chemical oxidation (ISCO) using sodium permanganate (NaMnO4) was conducted in 2000-2001 at the Tenneco Automotive site in Hartwell, GA, to evaluate feasibility of using ISCO to remediate a dissolved-phase trichloroethene (TCE) plume in a fractured bedrock aquifer [see May 2004 TNT]. The ISCO pilot was initiated to develop an alternate remedy for the off-facility plume; pump and treat technology was initially considered. Difficulties in groundwater remediation were compounded by offsite plume migration through connective fractures to 52 adjacent residential and commercial properties. Pilot test results demonstrated that ISCO could effectively remediate chlorinated volatile organic compounds (CVOCs), which led to full-scale ISCO implementation in 2003. The pilot test also highlighted the need for developing an effective hydrogeologic conceptual model in this type of complex geologic regime, namely fractured bedrock.

Prior to pilot testing, TCE was present in groundwater at concentrations reaching 12,000 µg/L in an onsite well and 330 µg/L in an offsite commercial well in the north plume area. The site is situated in Piedmont metamorphic and granite rocks that have weathered into a 20- to 50-ft layer of residual soil (saprolite) near ground surface. Hydraulic conductivity of the saprolite is approximately 1x10-4 cm/s. A more permeable zone of partially weathered rock (PWR) exists beneath the saprolite and above unweathered bedrock, at a typical depth of 50-60 ft bgs. Impacted groundwater exists primarily in the PWR, which has an average hydraulic conductivity of 1x10-2 cm/s (30 ft/day) and an average groundwater flow rate of 100 ft/yr in the offsite plume area. A bifurcated TCE plume in the unconfined PWR aquifer extends approximately 1,800 feet west beneath the facility and nearly 1,700 feet northeast into adjacent offsite properties (Figure 4).

The Phase I pilot test was conducted using an existing recovery well and a single monitoring well located approximately 30 feet from the recovery well. The initial field injection employed one gallon of a 40% NaMnO4 solution mixed with the monitoring well water to produce a 2.5% solution that was injected into the subsurface through the well. Post-injection testing of water quality parameters such as pH, temperature, dissolved oxygen, and ORP indicated that oxidation of TCE by NaMnO4 had occurred. Direct correlations between the lowest TCE concentration and an increased chloride concentration (3:1 ratio) and the highest ORP measurement provided additional evidence of TCE oxidation.

Phase II pilot testing was conducted using an existing offsite monitoring well screened in the PWR and located on commercial property with the highest offsite TCE concentration in groundwater (330 µg/L). Four additional PWR monitoring wells were installed upgradient of the existing monitoring well at 20-ft intervals. A total of 7,780 gallons with an average NaMnO4 concentration of 210 mg/L was injected into a single well during four events in May 2001. Over the next three months, four additional 500-gallon injections were completed with NaMnO4 concentrations of 5,600 mg/L. Phase II results indicated that TCE concentrations in each of the monitoring wells decreased significantly after the NaMnO4 injections.

Overall pilot results indicated that no daughter products had formed, oxidant demand was minimal (less than 10 mg/L), and TCE concentrations were reduced to below the maximum contaminant level (5 µg/L) in three of the five wells. In addition, NaMnO4 was highly persistent in the aquifer (more than one year), no screen fouling was observed, and metal mobilization did not occur. The results of pilot-scale ISCO prompted refinement of the site conceptual model to include a better understanding of fracture porosity in the PWR.

Current full-scale ISCO implementation has built upon lessons learned during the two pilot tests, the most important of which was the need to use relatively small injection volumes (only a fraction of estimated pore volume) in order to minimize displacement of treated groundwater. Full–scale operations began with the installation of 12 new wells, (8 injection and 4 monitoring wells) in the north off-facility portion of the plume. The first series of semi-annual injections was conducted in February 2003. Single injections ranging from 250 to 500 gallons in volume were accomplished through gravity feed of a 2% NaMnO4 solution to the screened zone of eight wells. Similar injection events have been conducted semi-annually since October 2003 and are scheduled to continue at least through the end of 2011. The extended treatment duration is needed mainly because of owner restrictions regarding the quantity and location of injection wells on private property in the north plume area.

Spring 2008 sampling results indicate that the areal extent of the northeast plume has decreased approximately 30% since full-scale ISCO began (Figure 4). The maximum TCE concentration has declined to 120 µg/L, and two of the ISCO monitoring wells now meet the TCE target of 5 µg/L. Mann-Kendall statistical analysis of TCE concentrations in five wells within the treatment area shows a statistically-significant decreasing trend in three wells and no significant trend in the other two. Reduction of TCE concentrations within the plume also is suggested by decreased TCE concentrations measured in the nearby Jail House Branch and its tributaries (Creeks A and B, Figure 4). Continued plume reductions beneath impacted properties are expected to lead to several property delistings from the mandated remediation program as early as 2010. ISCO project costs at Tenneco Automotive total approximately $525,000, to date, including $85,000 for the two-phase pilot testing, $170,000 in capital costs, and $45,000 for annual O&M that includes periodic injections. Development of the site conceptual model, which included adjacent onsite and offsite areas addressed by other remedies, incurred an additional $1 million.

Contributed by Charlie Spiers, GeoSyntec Consultants (cspiers@geosyntec.com or 678-202-9500), Jason Metzger (jmetzger@gaepd.org), and Carrie Williams (cwilliams@gaepd.org), State of Georgia/Environmental Protection Division (404-657-8600)