This issue of Technology News and Trends highlights site remediation involving in-situ application of heat or electrical current to treat soil or ground water containing volatile organic compounds (VOCs), including non-aqueous phase liquid. These projects demonstrate significant cost and time savings gained over conventional remedies such as soil excavation or ground-water pumping with limited aboveground treatment, and suggest methods to address common difficulties such as treatment of heterogeneous contaminant sources or verification of system performance.

Innovative E-Barrier Controls Ground-Water Plume of Energetic Compounds

CLU-IN Resources

CLU-IN's "Technology Focus" (http://cluin.org/techfocus/) provides guidance, cost and performance reports, and case studies on in-situ thermal technologies such as electrical resistance heating, hot-air injections, hot-water injections, steam injections, radio-frequency heating, thermal conduction, and vitrification. Similar material is available for ex-situ technologies such as thermal desorption, hot-gas decontamination, plasma high-temperature recovery, pyrolysis, and thermal off-gas treatment.

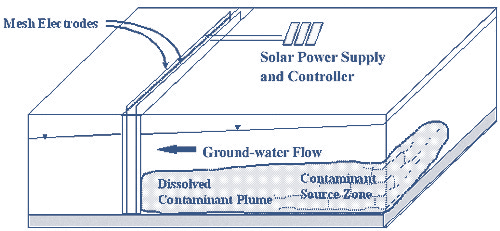

Demonstration of an emerging technology known as the electrolytic reactive barrier (e-barrier) is underway at the Pueblo Chemical Depot near Pueblo, CO. This technology combines the principles of electrochemistry with those of permeable reactive barriers to manage ground-water plumes contaminated with chlorinated solvents or energetic compounds. Under the federal Environmental Security Technology Certification Program (ESTCP), evaluation of the Depot's e-barrier focuses on its performance in treating RDX, TNT, and 2,4-DNT in ground water and on the relationships between the system's power requirements and performance. Efforts to reduce electricity costs for powering this already low-energy treatment method are enhanced by an off-grid solar photovoltaic (PV) system.

Environmental restoration at the Pueblo Chemical Depot was initiated in 1988 after closure of the base under the Base Realignment and Closure Program. The demonstration site encompasses a former munitions washout facility where unlined holding ponds leached RDX, HMX, TNT, 2,4-DNT, 1,3,5-TNB, ammonium, and nitrate into ground water. The source was partially excavated in 1997-1998 and contaminated soil was composted; however, concentrations of energetic compounds in ground water remained high. Source concentrations in the treatment zone average 35 µg/L for RDX and 5 µg/L for 2,4-DNT. Based on site-specific condtions, the State of Colorado set cleanup goals at 0.55 µg/L for RDX and 0.0885 µg/L for 2,4-DNT.

The contaminant plume resides within an alluvial sand and silt matrix with a saturated thickness of about 3 feet, underlain at 12 feet by a shale aquitard with ground-water flow rates averaging 6 in/day. The plume extends approximately two miles downgradient from the source area. To address high concentrations of RDX in off-site irrigation wells, a pump and treat system employing granular activated carbon and ion exchange has operated at the Depot since 2001.

An e-barrier consists of closely spaced mesh titanium electrodes mounted to rigid, non-conductive sheet piling. The barrier is installed vertically to intercept the contaminated plume and functions as a permeable reactive barrier (Figure 1). Low-voltage direct current is applied to the electrodes to drive electrochemical oxidation of contaminants at the anode and reduction of contaminants at the cathode. DC/DC converters allow adjustment of voltage to optimize treatment. Depending on target contaminants, the e-barrier can be operated in either a sequential oxidation–reduction mode or sequential reduction-oxidation mode. Multiple sequences may be employed to completely degrade target contaminants and any intermediate compounds.

The Depot e-barrier comprises 15 individual electrode modules mounted to commercially available vinyl sheet pile. Conventional cranes were used to load each 2-ft by 8-ft section of electrode mesh-covered sheet piling into the 4-ft e-barrier trench. Once emplaced, modules were linked to form a continuous barrier with an estimated ground-water residence time of eight hours in the vicinity of the electrodes. The trench was backfilled with clean, coarse sand obtained from a local quarry.

PV panels are used to power the system due to the Pueblo area's high solar-energy rating, averaging 4.5 kWh/m²/day. A single 2-kW, non-tracking PV array equipped with storage batteries provides sufficient power to operate all of the system modules. Though energy consumption varies according to applied voltage, current operation of the e-barrier at an applied potential of 5.3 V results in an energy demand of 500 W.

Treatment began in March 2006. Tests using applied voltages of 2.3, 3.3, and 4.3 V are complete, and testing of 5.3 V began in June 2007. Performance is monitored at 26 monitoring wells located up- and downgradient from the e-barrier. To date, degradation of RDX has ranged from 70% at 4.3 V to 40% at 2.3 V, with no apparent formation or accumulation of known intermediates. Similar rates of 2,4-DNT and TNT transformation to compounds more thermodynamically amenable to treatment have been observed, supporting previous experiments that found treatment efficacy directly relates to applied potential.

Results suggest that a threshold of 5 V is needed to optimize reactions within the e-barrier while avoiding undesired reactions. Extreme redox conditions (pe and pH) developing at electrode surfaces, even at low voltages, potentially cause formation of precipitates on electrode surfaces. Although this problem may not occur at sites with more favorable ground-water geochemistry, it was resolved at the Depot by reversing polarity for one hour each day using a programmable logic controller.

A remote data-acquisition system collects electrical data such as current and electrode potentials at 15-minute intervals. In addition, cellular modem connection provides real-time monitoring of the electrical system and access to its data logger.

Project costs are estimated at $24/ft² for installation and $1,200 for each e-barrier module, for which a 20-year lifespan is estimated. Project results will be detailed in a future cost and performance summary. Pending final results of the demonstration and funding availability, full-scale operations involving additional transects at the Depot may begin in 2009. Earlier demonstration of e-barrier prototypes at Warren Air Force Base (see cost and performance summary at www.estcp.org) and Canadian Forces Base Borden showed that simple reversal or shifting of electrode polarity allows the technology to treat chlorinated solvent plumes.

Contributed by David Gilbert, Ph.D.(gilbert@engr.colostate.edu or 970-491-8880) and Tom Sale, Ph.D., Colorado State University (tsale@engr.colostate.edu or 970-491-8413), and Chris Pulskamp, Pueblo Chemical Depot (Christopher.Pulskamp@us.army.mil or 719-549-4252)

Three-Phase System Improves ERH Control in Removing Source-Area VOCs

The U.S. Navy increasingly uses three-phase electrical resistance heating (ERH) to remove VOCs from contaminant source areas on Navy facilities. One site is the Naval Station (NS)-Annapolis, MD, where ERH was conducted in 2006 in a portion of the area known as "Site 1." As part of a CERCLA interim removal action, the primary objective of ERH application was 95% removal of bulk contaminants in source-area soil to reduce potential for contaminant migration to ground water. After ERH system shutdown, the volume of VOC mass removed by the system more than doubled the amount originally targeted.

Site 1 covers 39 acres along the north shore of the Severn River and directly across from the U.S. Naval Academy. From 1944 until 1973, the site was used for metal storage and salvaging operations. The Navy commissary/exchange building and parking areas currently occupy the site's northwestern portion, and the remainder is primarily wooded. The ERH treatment area is located directly behind the commissary and exchange building's loading dock.

A 1988 site investigation identified elevated concentrations of VOCs in ground water, likely resulting from past metal salvaging. Contamination consisted primarily of 1,1,2,2-tetrachloroethane (TeCA) and trichloroethene (TCE) at concentrations reaching 45,000 ug/L and 2,800 ug/L, respectively. Subsequent investigations identified a 150- by 110-foot vadose-zone source area extending in soil from a depth of 10 feet below ground surface (bgs) to 65 feet bgs. Studies showed no direct exposure to contaminated soil in the source area, which now is covered with asphalt or grass.

Remedial alternatives for subsurface soil included ERH, soil vapor extraction (SVE), and excavation. Life-cycle costs for ERH and SVE were comparable, but SVE was projected to require up to seven years of operation to remove the target VOC volume, and ERH was estimated to remove the same amount in less than one year. Soil excavation was not a viable cost option due to the depth of contamination. To optimize capital and operating costs, extensive sampling was conducted to fully delineate the treatment area and determine the minimum number of electrodes needed.

ERH technology promotes contaminant volatilization through a combination of steam stripping and in-situ degradation that removes dissolved-phase contaminants. Its performance relies on critical spacing of electrodes for heating the subsurface while targeting contaminant depths and concentrations. At NS-Annapolis, electrodes were placed in vadose- and saturated-zone VOC recovery wells. Each electrode boring included a co-located vapor recovery well. Instead of using sand to backfill around the electrodes, as in conventional well installations, an electrically conductive material (graphite) was emplaced in the wells at target depths. Unnecessary heat conductance and associated electricity costs at the periphery, where contamination was shallow, were minimized through use of shorter spans of graphite. Five temperature-monitoring points were used to measure temperatures at 5-ft intervals from 5 ft to 75 ft bgs.

Two drilling methods were needed to install wells to a target depth of 72 feet. An air rotary rig drilled through sand, silt, clay, and a 10-foot iron layer to reach the saturated zone located 60 feet bgs. A hollow-stem auger was used to preserve integrity of the well walls during drilling of the remaining 12 feet and for electrode placement.

The system includes 24 steel electrodes, a conventional-electricity power control unit (PCU), a steam condenser, granular activated carbon (GAC) filters, and an SVE blower. Electrodes were installed in a triangular grid for three-phase, instead of more common six-phase, heating to achieve more uniform heating of the subsurface. All portions of the electrodes were installed underground to avoid interference with ongoing site activities.

Soil vapors and contaminant-laden steam were transported through the combined electrode/recovery wells to the system's aboveground condenser, where soil vapors and VOCs were separated from steam. Resulting condensate was recycled in the condenser system as supplemental cooling water. Air and VOC vapors passed from the condenser through GAC filters to the SVE blower for atmospheric discharge. Emission tests during the heating process showed no VOC concentrations exceeding air standards.

The selected PCU allowed manual and fully remote computer-based control of the ERH system, which required 100-amp, 13.8 kV power to apply 2,000 kW of electricity to the source area. Current was applied to the subsurface for 116 days in February-May 2006. Subsurface temperatures averaged 99°C throughout the heating process, reaching a maximum of 107°C. Pre-treatment tests suggested a target temperature of 100°C.

Operations were suspended only once early in the project to address blower noise affecting a nearby residential neighborhood. Addition of a muffler to the inlet and outlet lines of the blower achieved a 75% reduction in noise, and operations resumed four days later.

Daily measurement of VOC concentrations in vapor streams of the condenser's outlet indicated a total VOC volume of 1,800 pounds was removed from soil over the course of treatment. This volume significantly exceeded a pretreatment estimate of approximately 850 lbs, showing higher than anticipated ERH performance as well as under-estimate of the original volume.

Call for Abstracts

The U.S. EPA Office of Superfund Remediation and Technology Innovation and the Environmental Institute/University of Massachusetts Amherst are co-sponsoring a conference on Triad Investigations: New Approaches and Innovative Strategies on June 10-13, 2008, in Amherst, MA. Abstracts for platform or poster presentations must be submitted by November 1, 2007. Visit http://www.umass.edu/tei/ conferences/triad.html for more information.

Ground-water sampling was conducted before system operation, immediately after system shutdown, and at three- and six-month intervals after shutdown. At the three-month interval, some contaminant rebound was observed in the treatment area, and TCE concentrations in downgradient wells exceeded pretreatment measurements. These concentrations decreased significantly by the next round of sampling. Six-month sampling indicated total VOC concentrations in the well closest to the treatment area decreased at least one order of magnitude, with TeCA and TCE concentrations falling to levels below 10 µg/L and 1,500 µg/L, respectively.

Over the course of active heating, the system's electricity consumption totaled 1,710,726 kW-hrs. Electricity costs comprised 19% of the $1.7M total project cost, including installation and operation. Soil sampling to verify ERH results will occur next year following complete cooling of the subsurface.

Contributed by Jennifer Melton, U.S. Navy (jennifer.melton@navy.mil or 202-685-3275)

Steam Injections Combined with SVE Accelerate Cleanup of Brownfield

The Port of Ridgefield in Washington is conducting steam-enhanced remediation (SER) as an interim/emergency action to remove a ground-water contaminant source and control migration of a free-phase plume into the Ridgefield National Wildlife Refuge of the Columbia River basin. The treatment area comprises four acres of the Port's 41-acre Lake River Industrial Park, a brownfield requiring restoration before mixed-use redevelopment. In cooperation with the State of Washington Department of Ecology, the Port estimated that cleanup using conventional ground-water pumping and aboveground treatment (P&T) would take up to 90 years. Early results of SER/SVE treatment confirmed that significant reductions in cleanup duration could be achieved through technologies other than P&T. During the initial year of its application, alone, SER/SVE technology removed the same volume of subsurface contaminants expected to be removed by P&T in 6.5 years.

Pacific Wood Treating Corporation treated wood for approximately 30 years on this Port-owned property located approximately 10 miles north of Vancouver. Chemicals used during wood-treating included creosote, pentachlorophenol, and water-borne solutions containing copper, chromium, and arsenic. These chemicals were released to the soil and ground water and eventually threatened to migrate to Carty Lake, now part of the wildlife refuge. Investigations indicate that the site’s shallow (20 ft bgs) ground water contains a plume with more than 100,000 gallons of free-phase chemicals. Soil in this area consists of a 50-ft layer of fine to course sand and cobbles overlaying a cemented gravel aquitard.

SER implementation began in 2004 with an initial phase to start hydraulic control of the plume containing semivolatile organic compounds, begin mass removal, optimize the SER system, and fine-tune a design for expanded operation. Treatment targeted a one-acre area with initially one injection well; later during this initial phase, five more injection wells were added. Each well received continuous steam injection over an average of 180 days, at an average rate of 2,000 lbs/hr. Performance information helped adjust well spacing during subsequent full-scale installation and determine an energy consumption goal of 500 kW-hr/m³ for each cubic meter of soil treated. Approximately 4,700 gallons of nonaqueous-phase liquid (NAPL) were removed during the initial phase.

In 2006, the full-scale SER system was installed and operations began to treat four areas sequentially. Current objectives are to remove NAPL, the contaminant source, and mobile contaminants from both soil and ground water. Based on first-phase results, the expanded system generally maintains a 2:1 ratio between the amount of ground water extracted and the amount of cold-water equivalent of steam injected. Each injection is designed to apply approximately four pore volumes of steam.

The system employs 51 injection wells (spaced 86 ft apart) and 40 vapor/ground-water extraction wells (spaced 50 ft apart) in addition to the pilot project's 17 combined ground-water and vapor extraction wells. The 4-inch-diameter steel injection and extraction wells have 10-ft and 35-ft screens, respectively. Each well is grouted in place with a mixture of silica flour and Portland cement to provide a good well seal and prevent steam escape at the surface.

The system includes a 100-gpm liquid treatment system and 1,500-scf vapor treatment system housed in a 100- by 100-ft aboveground facility. Treatment of extracted liquid involves sequential use of two parallel heat exchangers, two parallel bulk oil/water separators, coagulation/flocculation units, an inclined plate clarifier, two parallel mixed media filtration skids, and three GAC beds. Extracted vapors are treated in a separate treatment train using a "fin-fan" heat exchanger, air/liquid separators such as knockout pots, air dryers, and two steam-regenenerated GAC systems. Treated liquids are discharged into Lake River, an adjacent tributary of the Columbia River under an NPDES permit.

Full-scale enhancements included use of hammerhead airlift pumps rather than progressive cavity pumps for better maintenance of hydraulic control during extraction and ease of in-field repair; other pumping methods failed due to heat build-up and associated chemical reactions. To increase the rate of removing light NAPL, a second vacuum system was added, whereby 1-inch flexible "slurping" tubing is used to draw liquids off the ground-water surface.

Full-scale operations began in January 2006 to address the 4-acre treatment zone in 1-acre increments, each employing 8-10 injection wells supported by 20-30 extraction wells. Each well received continuous steam injection over an average period of 180 days, at an average rate of 2,000 lbs/hr. Approximately 60,000 gallons of contaminated liquid, averaging about 120°F upon extraction, were treated at the water treatment plant each day. Automated systems allow simultaneous monitoring by the Port and WA Department of Ecology, which oversees the cleanup. In contrast to earlier steam-injection projects based on NAPL removal from an aquifer, performance monitoring indicated that the majority of NAPL floats on top of the water table.

Treatment in the first 1-acre area was suspended in June, when approximately 16,600 gallons of NAPL had been cumulatively removed. The material was placed in onsite storage tanks pending offsite incineration. Work focus was turned to the next 1-acre area in order to maximize treatment returns on the NAPL recovery, and begin monitoring of "polishing" technologies such as hydropyrolysis/oxidation and natural bioremediation.

Cleanup costs are anticipated to total $48M. Use of the Port's existing steam generator reduced construction costs, and operation of the system by in-house Port personnel significantly reduces operating costs. Approximately $6M and three years of system operation also were saved by installing the complete well field at one time rather than through four rounds of field mobilization.

Steam injection in the second 1-acre treatment area began this past July, with expected completion in 6-9 months. SER across the entire four acres is anticipated to be complete by 2013-15. The Port has begun assessing risk associated with residual (primarily non-mobile) contamination in the treatment area as part of a current remedial investigation/feasibility study.

Contributed by Brent Grening, Port of Ridgefield (bgrening@portridgefield.org or 360-887-3873), Dan Alexanian, WA Department of Ecology (dale461@ecy.wa.gov or 360-407-6249), and Steven Taylor, Maul Foster & Alongi, Inc. (staylor@mfainc.org or 360-694-2691)

ERH Removes VOC Contaminants Under Cold and Low-Permeability Conditions

The U.S. EPA's Region 8 recently remediated soil and ground water at a VOC-contaminated site in West Fargo, ND, using thermally enhanced vapor extraction relying on ERH technology. Though the treatment area encompassed only 10,300 ft² of a former dry-cleaner site, an extensive heating system was required to reach cleanup goals in the region's cold climate. Remediation was further challenged by the presence of dense NAPL, an extremely low-permeability subsurface, and the site's location next to residential and commercial properties. Acceleration of this Superfund removal action was needed to protect the small city's drinking water source, a municipal well only one-quarter mile from the site.

Treatment was designed to target five depths ranging from 0 to 56 ft bgs to treat a total soil volume of approximately 13,800 yd³. Concentrations of PCE, the primary contaminant of concern, reached 2,200 mg/kg in soil consisting primarily of clay with goethite infilling between joints and fractures. The highest PCE concentration in ground water, encountered at 3-7 ft bgs, was 89 mg/L. In contrast to a typical conductivity of 200-1,000 µS/cm, ground water at this site exhibits a natural conductivity ranging from 8,000 to 12,000 µS/cm. This condition required application of extremely high-current, low-voltage electricity to heat the subsurface. Based on site-specific conditions and the technical practicability of the thermal technology, cleanup goals were set at 3 mg/kg PCE in soil and 1 mg/L total VOCs in ground water.

The ERH system included 56 multi-zone electrode/vent assemblies and an array of horizontal vapor extraction wells. An additional 74 dual vacuum extraction (DVE) wells were added midway through the project to augment contaminant extraction in the low-permeability clay. Subsurface temperatures were monitored with 10 temperature-monitoring piezometers, and nine multi-level perimeter monitoring wells were installed on the site perimeter to evaluate pre-treatment conditions and monitor any contaminant migration. Extracted vapor and condensate were treated with activated carbon. A temporary building was constructed to cover the entire area, avoiding the need to winterize individual components of the treatment system.

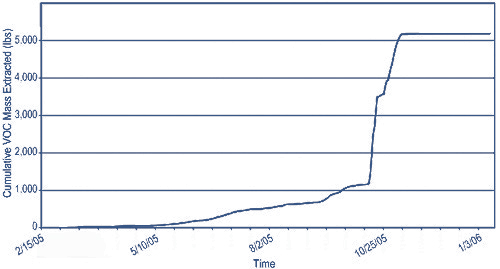

Site construction began in June 2004. Active subsurface heating began the following March, when average daily temperatures rose to a high above 32°F and average monthly snowfall dropped to below nine inches. Three 36,000-amp power supply units converted conventional electricity to 750 kW of power at voltages ranging from 70 to 950 V. The target subsurface steam temperature of 100°C was achieved within three months (in May), and the system operated for an additional six months (until November) (Figure 2). The DVE system continued to operate for three more months while the subsurface cooled.

A total of 5,188 pounds of VOC mass was removed within one year after treatment startup. Soil and ground-water sampling upon ERH shutdown confirmed target concentrations were reached at all locations of the treatment area, except one on the periphery where contamination was not fully defined. Some subsidence of clay was observed during the treatment process.

Over the course of treatment, a total of 2.8 mW-hrs of energy was consumed. Cleanup costs, including site restoration, totaled approximately $3M.

Contributed by Joyce Ackerman, EPA Region 8 (ackerman.joyce@epa.gov or 303-312-6822)