This issue of Technology News and Trends highlights assessment and remediation of sites where past use of tetrachloroethene (PCE) at drycleaners resulted in environmental contamination. Topics include commonly used technologies such as soil vapor extraction (SVE), bioremediation, and in situ chemical oxidation (ISCO); renewable energy to power these technologies; and studies on controlling contaminant vapor mitigation.

Three-Pronged Remedial Approach Used at Highly Contaminated Site in Florida

Online Resources

The State Coalition for Remediation of Drycleaners (SCRD) offers online profiles summarizing remediation systems at 177 drycleaner sites. Other SCRD searchable databases or online publications address common issues at drycleaner sites such as the variable chemistry of solvents, vapor intrusion, and suitable site characterization technologies. To learn more or subscribe to the SCRD's semi-annual newsletter, visit: www.drycleancoalition.org/.

Approximately 14% of the 314 drycleaning sites assessed by the Florida Drycleaning Solvent Cleanup Program (DSCP) to date have groundwater with PCE concentrations exceeding 15,000 µg/L (10% of the aqueous solubility of PCE). These sites are considered highly contaminated and likely contain dense non-aqueous phase liquid (DNAPL) in the saturated zone, making them the most costly and challenging to remediate. One such site is the Holiday Plaza French Cleaners in Pembroke Pines. Since 2005, the cleanup has involved excavation followed by SVE and, more recently, bioremediation. Sampling results compiled earlier this year indicate a 99% reduction in source area PCE concentrations due to the cleanup measures.

Drycleaning operations using PCE were conducted at this shopping center facility from 1982 until 1999 when it was converted to a dry drop-off operation. In early 2004, direct push technology, a mobile laboratory, and a sonic drilling rig were used to collect and analyze soil and groundwater samples. Results revealed two contaminant source areas: a stormwater drainage system within a service alley behind the drycleaning building, and soil beneath the floor slab (in the upper 30 feet of the saturated zone near the former drycleaning bay).

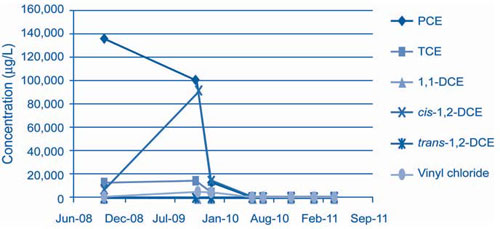

The highest contaminant concentrations detected in sediment collected from the stormwater drain were 6 mg/kg PCE, 19 mg/kg trichloroethene (TCE), 5.5 mg/kg cis-1,2-dichloroethene (DCE), and 2.5 mg/kg vinyl chloride (VC). In groundwater, the highest concentration of PCE was 135 mg/L, which suggested the presence of free-phase PCE. PCE degradation products were detected in groundwater at concentrations reaching 17.2 mg/L TCE, 90.4 mg/L cis-1,2-DCE, 4.9 mg/L trans-1,2-DCE, and 6.5 mg/L VC.

The lithology consists of medium-grained sand with limestone stringers to approximately 34 feet below ground surface (bgs). From 34 to 38 feet bgs, fossiliferous limestone overlies limestone extending to 90 feet bgs. Depth to groundwater at the site ranges from 5 to 6 feet bgs.

In August 2005, cleanup was initiated through an interim source removal involving excavation around the readily accessible storm drain. The target area covered about 18 by 56 feet to a depth of 5 feet except around the drain, where excavation extended to 10 feet bgs. Approximately 120.6 tons of contaminated soil and sediment were removed, and the stormwater system was reinstalled. After excavation, a 94% decline in total VOC concentrations in groundwater was measured in a water table monitoring well near the drain.

In May-July 2009, the SVE system was constructed to address contaminated soil under the drycleaning building and part of the service alley. Three vertical wells were installed, two beneath the building floor slab and the third in the alley. Each well was constructed of 4-inch-diameter PVC pipe screened from 1 to 4.5 feet bgs. Through use of a 15-hp rotary blower, the system operates at an average flow rate of 150 cfm with an operating vacuum of 1.3 psi. Well offgas is treated in a 140-pound granular activated carbon (GAC) vessel.

In situ biostimulation was selected as the groundwater remedy due to evidence that reductive dechlorination occurs at the site anaerobically. Indicators included low dissolved oxygen (ranging from 0.2 to 0.7 mg/L) and an oxidation-reduction potential of -201 to -101 mV (near the ideal range for reductive chlorination). The presence of ethene and ethane as PCE degradation products, along with existing microbial populations known to degrade chlorinated hydrocarbons (Dehalococcoides ethenogenes), provided additional evidence.

The carbon-rich amendment chosen to stimulate bioremediation was an emulsified oil substrate consisting of soybean oil, fast-release sodium lactate, food additives, extracts, and water. Since installation of injection wells beneath the shopping center was infeasible, a groundwater recirculation system using two 1.5-hp submersible pumps was designed to distribute the reagent across the source area. The recirculation system consisted of four 5-inch-diameter wells in two-well clusters, one for injection and one for recovery. One of the wells in each cluster was screened at a shallow depth (10-30 feet bgs) and the second was screened 20 feet deeper. The injection cluster was positioned adjacent to the former drycleaning bay with the extraction cluster approximately 100 feet away, on the opposite side of the building. The anticipated extraction rate for each well was 30 gpm, with an estimated 41 days for the solution to disperse under the building.

In July 2009, 275 gallons of substrate and 24,960 gallons of water were injected into the shallow-zone well, yielding an injection concentration of 1.09% (equivalent to a carbon application concentration of 7,903 mg/L). For the deeper zone, 275 gallons of substrate and 36,480 gallons of water were injected to achieve a concentration of 0.75% (5,426 mg/L carbon). Vitamin B12 was also injected in each well to provide additional microbial nutrition. The injection occurred at a rate of one liter of substrate per minute followed by chase water at 30 gpm.

Shortly after concurrent startup of the groundwater recirculation system, the annular seal for the shallow injection well failed. A second shallow injection well was immediately installed but its seal also failed. As a result, operations were modified to allow future injections/recovery at lower flow rates, and the shallow recovery well's 1.5-hp pump was replaced with a 0.75-hp pump. Subsequent shallow-zone recovery rates were reduced from approximately 32 gpm to 18 gpm, but injection rates in the deeper wells remained at approximately 38 gpm.

A second injection was conducted in April 2010. A total of 357.5 gallons of the same substrate and 23,500 gallons of water were injected in the shallow zone to yield a 1.5% concentration (10,867 mg/L carbon). In the deeper zone, 357.5 gallons of substrate and 61,000 gallons of water were injected for a 0.58% concentration (4,225 mg/L carbon).

Fouling occurred in the shallow recovery well four months after the second injection and in the deep recovery well 1-2 months later. As a result, recirculation was suspended. Through September 2010, the shallow recirculation system had recovered/re-injected approximately 4.5 million gallons of water and the deep recirculation system recovered/re-injected approximately 15.4 million gallons. Extracted groundwater was treated in two 2,000-pound GAC vessels operating in parallel.

Significant declines in contaminant concentrations, along with apparent conversion of PCE to daughter products, indicate that the soil and groundwater treatment successfully accelerates reductive dechlorination. As of January 2011, comparison of pre-treatment contaminant concentrations in the source area monitoring well near the storm drain (where previously excavated) showed a 99.8% reduction of PCE, 98.9% reduction of TCE, 91.3% reduction of cis-1,2-DCE, and 70.9% reduction of VC (Figure 1). Monitoring of the second source area, beneath the building floor slab, showed PCE was reduced by 99.2%, TCE by 95.6%, and cis-1,2-DCE by 71.8%, with a 323% increase in VC (from a detection limit of 620 mg/L to 2,000 mg/L).

The Florida Department of Environmental Protection (FL DEP) anticipates continued operation of the SVE system and a third injection following rehabilitation of the biofouled recovery wells later this year. Costs for the project, which is administered and funded under the State's DSCP, total approximately $750,700 to date, including site assessment ($185,800), excavation ($141,700), design and construction of the SVE and biostimulation/recirculation systems ($248,200), and operation and maintenance ($175,500).

Contributed by Bill Linn, FL DEP (william.linn@dep.state.fl.us or 850-245-8939) and Guy Frearson, AECOM USA, Inc. (guy.frearson@aecom.com or 954-745-7211)

Renewable Energy for Drycleaner Cleanups

Site remediation at Busy Bee Laundry in Rolla, MO, illustrates how renewable energy can be used to power the cleanup equipment needed at many drycleaner facilities, including those where ongoing operations prevent use of obtrusive technologies. Solar energy is captured at the facility by a 540-watt photovoltaic (PV) array that directly powers a 400-watt piston pump extracting PCE-contaminated groundwater. The system extracts approximately 0.25 gallons of groundwater per minute from a depth of 35 feet bgs and transfers it to reactivated GAC vessels inside the laundry facility. Since January 2011 start-up, the system has removed nearly 1.7 kg of PCE. Latest results of the demonstration also suggest that use of a comparable low-cost PV array could provide significant benefits at other hazardous waste sites, including abandoned sites in remote locations or where continuous long-term dewatering is optimal.

To maximize capture of solar energy, the PV system includes a passive tracking mechanism (Figure 2). Selection of a pump that could operate on direct rather than alternating current eliminated the need for an inverter. The system also includes a timer that temporarily suspends pumping when the rate of groundwater flow drops below a pre-determined level, to allow well recovery. Supplemental recovery time as well as additional energy and cost efficiencies were gained by designing a low-flow system that could effectively treat the groundwater while accommodating unavailability of power during periods of low solar radiation.

During the first six months of operation, the system extracted and treated 32,112 gallons of groundwater at an average rate of 200 gallons per day. Performance analysis also indicated approximately 800 kWh of grid-supplied electricity were avoided through use of onsite solar energy. Based on the local electricity provider's fuel mix, this avoidance corresponds to an air emission reduction of 3,500 pounds of carbon dioxide, 11 pounds of sulfur dioxide, and 4 pounds of nitrogen oxides each year.

Capital costs for the PV system totaled approximately $3,600, including four PV panels, the passive tracker, and a linear current booster. Project costs were covered under the Missouri Drycleaning Environmental Response Trust (DERT) Fund with cooperative funding from Missouri University of Science & Technology (MO S&T).

Monitoring and maintenance of the PV system is conducted by the university's faculty and graduate students. More information about the project and other cleanups administered under the Missouri Drycleaning Environmental Response Trust Fund is available from the Missouri Department of Natural Resources (MO DNR).

Contributed by Vicky Kugler, MO DNR (vicky.kugler@dnr.mo.gov or 573-522-2093) and Curt Elmore, Ph.D., MO S&T (elmoreac@mst.edu or 573-341-6784)

Gravity-Feed as an Alternative to Pressurized Injections for ISCO

The Illinois Drycleaner Environmental Response Trust Fund (IDERTF) recently applied ISCO to treat heavily contaminated soil and groundwater at the Norgetown on Rand drycleaner in Arlington Heights, IL. Since the majority of contamination existed below the active drycleaner facility, a gravity-feed process offered a viable alternative to traditional oxidant delivery methods involving pressurized injections. Use of the gravity-feed system was expected to eliminate oxidant backflow (daylighting) and avoid creation of preferential pathways, which resulted during an earlier pilot study in which chemical oxidant was injected at pressures as low as 120 psi. In contrast, the maximum pressure of the gravity-feed system was equivalent to approximately 6 psi. Limited success of the pressurized injection pilot study was attributed to contaminant location in the soil above the water table.

A total of 21 groundwater monitoring wells were installed during the site investigation. Pre-treatment PCE levels in soil and groundwater were measured as high 24,000 mg/kg and 979 mg/L, respectively. PCE biodegradation products such as TCE, DCE, and VC were detected in samples but in much lower concentrations; the highest concentrations in soil and groundwater were 13.74 mg/kg and 15.42 mg/L for TCE, 7.30 mg/kg and 17.98 mg/L for DCE, and 0.47 mg/kg and 4.18 mg/L for VC.

The water table at the site is approximately 5.3 to 6.9 feet bgs. Soil in the target zone primarily consists of a sandy clay layer extending 12-16 feet bgs that overlies a clay layer at 16 feet bgs, although isolated areas contain significant sand content at 6 to 12 ft bgs. Shallow soil (0-20 feet bgs) exhibits a hydraulic conductivity averaging 2.71 cm/day (32.4 ft/yr) and hydraulic gradient of 0.018. The estimated porosity of soil is 0.20.

The selected oxidant sodium permanganate (NaMnO4) was delivered through 22 injection wells screened at 5-10 and 10-20 feet bgs. In addition, 10 of the monitoring wells (screened at 5-15 feet and 10-20 feet bgs) were retrofitted for oxidant delivery. The 32 injection points were intended to deliver oxidant throughout an approximate 1,000-ft2 area. Field observations during the initial stage of gravity feeding suggested a radius of influence (ROI) ranging from 2.5 to 6 feet. Prior to beginning the injections, the estimated ROI at each injection point was used to determine a suitable volume of oxidant for each point.

The injection process used six 65-gallon storage drums filled with NaMnO4 solution and positioned on 3-foot-high platforms inside the drycleaner building, near the drycleaning machine. Each drum was connected to an injection point by a single gravity feed line (Figure 3). Once an injection point was fed with the desired amount of oxidant, the next injection point was connected to the feed line until the process covered all 32 injection points.

Flow rates varied significantly from injection point to injection point, ranging from 0.07 gal/hr to about 80 gal/hr. Equipment failure due to fitting corrosion and feed-line air bubbles was experienced during the initial stage of gravity feeding but was easily corrected by replacing the fittings and rearranging the feed lines.

The first stage of treatment was completed over 59 days in March through May 2010, during which time a total of 360 gallons of 10% and 2,487 gal of 20% NaMnO4 solution was injected via 27 injection points. A confirmatory site investigation in August 2010 showed that although both the contaminant concentrations and plume size had significantly decreased, residual contamination levels in soil and groundwater at five sampling points were higher than the remedial objectives. As a result, an additional round of gravity-feed injections was conducted over 55 days in September through October 2010 at 10 injection points. A total of 2,300 gal of 3.3% NaMnO4 solution was fed to the remaining hotspot area during this follow-up injection.

No daylighting was observed, suggesting that the majority of oxidant had reached the target zone with minimal development of preferential pathways. Based on the oxidant feed rate and water table changes in nearby monitoring wells, contact time between the NaMnO4 and PCE was estimated at 3-5 days in the vadose zone and at least 25 days in the saturated zone. In contrast, the earlier pilot project involving pressurized injections showed no change in the water table, which suggested a significantly shorter contact time (less than one day) in the vadose zone.

Sampling conducted approximately 60 days after gravity feeding ended indicated a 99% reduction in PCE concentrations in soil (from 24,000 mg/kg to 160 mg/kg) and groundwater (from 978 mg/L to 6.6 mg/L and from 500.5 mg/L to 19 mg/L). A final confirmatory site investigation was conducted shortly thereafter with nine soil borings and groundwater samples from 12 monitoring wells. Only one soil boring showed residual TCE, at a concentration of 3.4 mg/kg, without residual DCE or VC. Groundwater sampling detected PCE degradation byproducts in only one monitoring well, where concentrations increased to 3.5 mg/L from 2.73 mg/L for TCE, to 33 mg/L from 2.6 mg/L for DCE, and to 0.65 mg/L from 0.045 mg/L for VC. These results suggest that indigenous PCE-reducing bacteria remain active.

The cost to implement gravity-feed ISCO was approximately $195,000, including $24,000 for confirmatory site investigations and $17,000 for well abandonment. System maintenance also accounted for a significant portion of the project cost due to the need for two to three site visits each week and the additional safety precautions required for storing large volumes of the chemical oxidant over several months.

Contributed by Juho So, Ph.D., IL DERTF Administrator, Williams & Co. Consulting (jso@willconsult.com or 800-266-0663) and Greg Dunn, IL EPA (greg.dunn@illinois.gov or 217-785-2359)

Evaluating the Effects of Vapor Migration Control Systems

Vapor mitigation studies at the Sharon Cleaners facility in Saratoga Springs, NY, and the Blue Ribbon Cleaners facility in Tallahassee, FL, revealed that vapor mitigation systems can induce unexpected effects on subsurface vapor migration. The study at Sharon Cleaners found that an active system installed at the facility helped limit vapor migration toward offsite buildings. At Blue Ribbon Cleaners, an evaluation of the lingering asymptotic soil vapor concentrations found the cause to be the soil vapor extraction (SVE) system drawing PCE into the subsurface from the facility, which was using PCE for drycleaning operations.

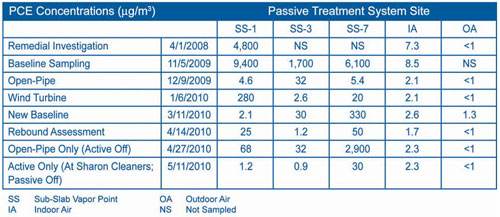

The initial objective of the New York State Department of Environmental Conservation (NYSDEC) six-month study of vapor intrusion mitigation at Sharon Cleaners was to compare the effectiveness of a passive open-pipe system and a passive wind-powered system with that of an active electrical vacuum system. An active sub-slab suction system driven by a 91- to 129-watt electric fan was installed at the drycleaner and at a residential building located 40 feet to the south. The two passive mitigation approaches were incorporated at a second residential building located 15 feet to the east of the drycleaner.

Data from sub-slab samples collected between November 2009 and May 2010 and during the remedial investigation in April 2008 show that a more significant reduction in PCE can be achieved through an active system. At both active systems, PCE concentrations declined from 3,000-23,000 µg/m3 to below 5 µg/m3. At the passive system, PCE concentrations decreased from 1,600-9,400 µg/m3 to 2.1-330 µg/m3 between November and March.

Because the passive and active systems were close to each other, NYSDEC evaluated whether the active system was influencing the results of the passive system. To do so, all systems were temporarily shut down in March 2010 and were reactivated and operated separately over a 2-month period. PCE concentrations at the passive system during this period ranged from 32 µg/m3 to 2,900 µg/m3 during passive treatment alone and between 0.9 µg/m3 and 30 µg/m3 during sole operation of the active system at the drycleaning facility (see Table 1). Based on these findings, NYSDEC concluded that the active system was altering vapor flow patterns and contributing to the PCE removal at the residential building with passive mitigation. NYSDEC anticipates continued operation of the passive and active systems at the drycleaner and both residential buildings until PCE concentrations within the indoor air and sub-slab soil vapor reach levels set by the New York State Department of Health.

At Blue Ribbon Cleaners, FL DEP conducted an 18-day study in April 2011 in response to consistent detection of low-level asymptotic PCE concentrations in the extracted soil vapors. Initial PCE concentrations in the extracted soil vapors were 11,000 µg/m3 when the SVE system began operating in September 2009. Within one month following SVE startup, PCE concentrations decreased to below 1,000 µg/m3 and remained asymptotic throughout the next year of active remediation. The objective of the study was to determine whether this observation was a result of volatilization of PCE from vadose zone soil or, possibly, mass flux migration from the drycleaner to the vadose zone.

The SVE system consisted of seven vapor extraction wells, four of which were installed in the sub-slab directly beneath the drycleaner. The estimated ROI of each vapor recovery well was approximately 30 feet. A 15-hp blower provided a vacuum beneath the drycleaning building. The study examined PCE concentrations in vapor at three locations: inside the drycleaner, in a vapor extraction well located beneath the drycleaner, and in the extracted soil vapors. Photoionization detectors were used to evaluate continuous PCE concentrations at each of the three vapor monitoring locations.

Samples indicated that PCE concentrations ranged from 39,340 µg/m3 to 79,350 µg/m3 inside the drycleaning building, with the higher value observed during the day when business was open, and the lower value when business was closed. Samples collected from the vadose zone indicated a similar trend.

The opposite trend was observed in samples collected from extracted soil vapor. PCE concentrations, which ranged from 350 µg/m3 to 980 µg/m3, were higher when the drycleaner was closed and lower when the facility was open and operating. PCE concentrations in extracted soil vapors fluctuated in a cyclic (nocturnal) pattern with a 4-hour time lag in the PCE mass flux from the active drycleaner through the concrete slab, increasing four hours after the drycleaner closed and decreasing four hours after the drycleaner was open and operating. The average PCE mass inside the drycleaner during operational hours was estimated to equal to the mass recovered by the SVE system when the drycleaner was closed (about 80 g), suggesting that the concrete slab provides little attenuation for vapor migration.

State Drycleaner Programs

Thirteen states currently operate programs dedicated to voluntary cleanup of contaminated drycleaner sites. Each program administers a legislatively-funded trust to help prioritize, finance, and implement these efforts. More information about the program and process in each state is available through: www.drycleancoalition.org/state.cfm.

FL DEP concluded that the distinct cyclical trends in PCE concentrations observed during the study indicated that PCE can migrate from an active drycleaner and be captured by an SVE system. Based on these findings, FL DEP shut down the SVE system immediately following the study. The site is currently being monitored for natural attenuation as specified in the site's remedial action plan.

Contributed by Aaron Cohen, FL DEP (aaron.cohen@dep.state.fl.us or 850-245-8962) and Brian Jankauskas, NYSDEC (bfjankau@gw.dec.state.ny.us or 518-402-9620)