- Mulch Dual-Wall PRB Promotes Anaerobic Degradation of Chlorinated Ethenes

- Subserface Injections of Emulsified Soybean Oil Accelearate PCE Biodegradation

- SERDP Study Identifies Subsurface Sampling Methods for Enhanced Decision-Making

- OSRTI Analyzes Trends in Superfund Cleanup Technologies

- State Coalition Reviews Remedies for Drycleaner Sites

Mulch Dual-Wall PRB Promotes Anaerobic Degradation of Chlorinated Ethenes

CLU-IN Resources

CLU-IN currently offers 18 regularly updated databases with remediation profiles compiled through past or ongoing initiatives of EPA’s Technology Innovation and Field Services Division. Database topics cover a range of remediation issues such as alternative landfill covers, in-situ thermal treatment, in-situ chemical oxidation, in-situ flushing, phytotechnology, MtBE, fractured bedrock, and pilot-scale systems. Details and search tools are available at http://clu-in.org/databases/#remed.

The Seneca Army Depot in Romulus, NY, employs a double-walled configuration for a full-scale permeable reactive barrier (PRB) to treat contaminated ground water at the Depot’s operable unit (OU) known as "Ash Landfill." Mulch was selected tentatively as the reactive medium two years ago, when rising costs for iron hindered expansion of an existing pilot-scale zero-valent iron (ZVI) PRB. The U.S. Army and EPA assisted the Depot in designing and installing the biowalls in 2006 to reduce the cost of reactive media as well as accelerate contaminant degradation and enhance contaminant plume control. Three rounds of post-installation monitoring indicate that the biowalls degrade virtually all trichloroethene (TCE), the primary ground-water contaminant of concern (COC), and demonstrate anaerobic degradation of TCE breakdown products both within and downgradient of the biowalls.

Over more than 60 years, the Depot was used for military equipment and material storage, supply, and maintenance, which commonly involved use of cleaning agents containing TCE. Cleanup of this National Priorities List site was initiated in the early 1990s under a federal facilities agreement among the Depot, EPA, and the New York State Department of Environmental Conservation. Site remediation accelerated in 1995 when the facility was designated for closure under the Base Realignment and Closure program.

The Depot encompasses 10,687 acres between Seneca Lake and Cayuga Lake in Seneca County. The Ash Landfill OU comprises five RCRA solid waste management units covering 130 acres. Of these, approximately 23 acres associated with the OU’s former multi-waste landfill are contaminated with volatile organic compounds (VOCs), semivolatile organic compounds, polycyclic aromatic hydrocarbons, and metals. The landfill is located near six designated wetlands and contains areas of potential historic and cultural significance.

Approximately 26,000 yd³ of contaminated soil serving as the source of ground-water contamination were treated in 1995 through low-temperature thermal desorption. Immediately prior to source removal, maximum COC concentrations in ground water were 960 µg/L TCE, 2,600 µg/L 1,2-dichloroethene (DCE), and 94 µg/L vinyl chloride (VC). Maximum concentrations in ground water five years later were 980 µg/L TCE, 760 µg/L DCE, and 29 µg/L VC.

The remaining ground-water plume is 1,100 ft long and 625 ft wide, and is vertically restricted to the upper till/weathered shale aquifer. Rates of ground-water flow in the treatment area range from 100 to 400 ft/yr. Chlorinated ethene concentrations above State of New York ground-water standards have not been detected in downgradient offsite monitoring wells.

In July 2005, two pilot-scale mulch biowalls were installed in the area with historically highest contaminant concentrations to demonstrate whether biowalls could degrade chlorinated ethenes and daughter products as effectively as the ZVI PRB. In addition to cost reductions, consideration of mulch as the alternate reactive media was prompted by longer-term demonstration of biowall performance and increased regulatory acceptance of biowalls at other chlorinated-ethene sites. Successful pilot-scale results over 18 months led to full-scale installation of an upgraded system last year.

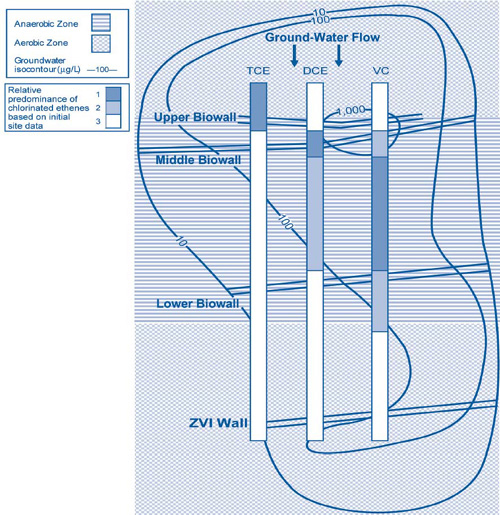

Mulch selected for this PRB system consists of coarsely shredded trees and brush from seasonal landscaping work in the Romulus area. A total of 2,800 yd³ of mulch, coated with 9,700 gallons of food-grade soybean oil, was mixed onsite with 2,000 yd³ of coarse sand. The mixture was emplaced in six trenches approximately 3 ft thick and 7-18 ft deep, forming a PRB consisting of three dual walls positioned perpendicular to ground-water flow from the source area (Figure 1). Parallel and partially pivoted alignment of dual walls with different lengths (370, 720, and 575 ft, sequentially downgradient) and different spacing (40 and 320 ft apart) allows the multiple treatment series to conform to the direction and breadth of ground-water flow. Design of the system allowed for continued use of the two pilot-scale walls, which were lengthened to serve as the "middle" dual walls.

Each dual wall consists of two parallel, filled trenches spaced 15 ft apart. This configuration allows the upper biowall in each pair to reduce concentrations of TCE and native electron acceptors such as sulfate, and the lower biowall to reduce TCE-degradation products such as DCE with less competition from alternate electron acceptors. In addition, the dual-wall construction method provides added reinforcement in areas of higher, localized, ground-water velocities. Driven by the natural hydraulic gradient, contaminated ground water passing through the biowall contacts the slowly soluble organic matter. This process provides a treatment zone extending between each pair of biowalls and as far as 200 ft downgradient from the entire system. A 12-in soil cover above the entire length of the biowalls impedes surface water infiltration. Before exiting the site, the plume is treated additionally by the earlier-installed ZVI wall, which still shows reactive capability.

Samples from 14 monitoring wells analyzed this past June show that total molar concentrations of chlorinated ethenes in ground water passing through the treatment zone decrease 86-99%. TCE concentrations in ground water decrease from 2,000 µg/L upgradient of the biowalls to 6 µg/L immediately downgradient of the lower pair of biowalls, and to 1 µg/L in a monitoring well immediately outside the site perimeter.

Concentrations of total organic compounds, reflecting the amount of carbon available for anaerobic degradation of contaminants, have increased from approximately 10 mg/L upgradient of the biowalls to 309 mg/L in the middle pair of biowalls. Concentrations of VC increase from an average of 3.3 µg/L upgradient of the upper biowalls to 81 µg/L approximately 42 ft downgradient of the middle biowalls. Additional evidence of ethene biodegradation in the treatment zone is provided by depleted concentrations of dissolved oxygen and sulfate, elevated concentrations of methane, and reduced oxidation/reduction potential.

Review of the project's engineering methods suggests that use of a continuous trencher rather than a conventional backhoe would have avoided sloughing of sidewalls during PRB construction. To date, no detrimental changes in hydrologic or geochemical conditions of the aquifer as a result of treatment have been observed. Degradation of the aquifier's remaining VC is expected to occur most readily in aerobic zones located upgradient and downgradient of the biowall system.

Project costs totaled approximately $288,000. Recharging of the biowall system through installation of injection points and injection of soybean oil into the mulch/sand mixture, at the relatively low cost of $75,000, is anticipated after 3-5 years of operation. Continued ground-water monitoring is conducted to confirm concentrations of TCE and VC meet state water-quality standards.

Contributed by Julio Vazquez, U.S. EPA Region 2 (vazquez.julio@epa.gov or 212-637-4323), Stephen Absolom, Seneca Army Depot (stephen.m.absolom@us.army.mil or 607-869-1309), and Todd Heino, Parsons (todd.heino@parsons.com or 617-449-1405)

Subsurface Injections of Emulsified Soybean Oil Accelerate PCE Biodegradation

The U.S. Air Force Center for Engineering and the Environment (AFCEE) recently completed a full-scale demonstration of enhanced in-situ anaerobic bioremediation at Former Newark Air Force Base (AFB) near Columbus, OH. An emulsion of vegetable oil and water was injected into the subsurface in two phases to stimulate anaerobic biodegradation of chlorinated ethene and ethane contamination in ground water. Within 24 months after the final injections, contaminant concentrations decreased to levels below cleanup goals at all but one monitoring location.

The demonstration took place at the "Former Facility 87" site (FF-87) located in the southeast corner of the 70-acre former AFB property surrounded by industrial, farming, and residential properties. FF-87 consisted of a semi-enclosed building that was used to store drums of used solvents and spent Freon 113 coolant. Chemical spills inside the building were controlled by drainage ditches and berms surrounding the building. Later site investigations, however, determined that spills on the building's asphalt floor migrated vertically downward to impact vadose-zone soils and ultimately the underlying ground water. The building was demolished and the building floor as well as contaminated subsurface soil were excavated and disposed offsite. The base's main production building, located cross-gradient from FF-87, is now zoned for industrial use and hosts the manufacture of aircraft equipment.

Cleanup goals were set at site-specific, risk-based standards of 5 µg/L tetrachloroethene (PCE), 5 µg/L TCE, 20 µg/L cis-1,2-DCE, 68 µg/L 1,1,1-trichloroethane (1,1,1-TCA), and 43 µg/L 1,1-dichloroethane (1,1-DCA). Prior to the demonstration, maximum concentrations were 1,300 µg/L PCE, 13 µg/L TCE, 46 µg/L cis-1,2-DCE, 150 µg/L 1,1,1-TCA, and 31 µg/L 1,1-DCA. Soil in the treatment area comprises approximately 8 feet of silty clay underlain by a silty to gravelly sand water-bearing unit. The sand water-bearing unit is in turn underlain by a second, lower permeability silt unit and finally by a low permeability clay aquitard. Ground water is encountered at approximately 9-14 ft below ground surface (bgs) and migrates at approximately 1,000 ft/yr within the sand unit. No evidence of dense non-aqueous phase liquid (DNAPL) was observed during pre-injection site investigations.

Food-grade vegetable oil was selected as the injectant substrate due to its low cost and ability to slowly release organic carbon over a long period of time (typically 2-5 years). Use of the organic carbon by native microoranisms depletes the aquifer's dissolved oxygen (DO) and lowers its oxidation-reduction potential, creating conditions conducive for anaerobic degradation of chlorinated VOCs. Once DO is consumed and reducing geochemical conditions are established, a portion of the vegetable oil-derived organic carbon is used for contaminant mass destruction through biologically mediated reductive dechlorination.

The initial injection in September 2001 employed a vegetable oil emulsion consisting of 25% partially hydrogenated lecithin-enhanced soybean oil and 75% native ground water extracted from an upgradient monitoring well showing COC concentrations below maximum contaminant levels. Pre-injection field preparations involved installing a network of six injection wells, nine ground-water monitoring points, and two soil-vapor monitoring points. Approximately 3,200 gallons of vegetable oil-in-water emulsion containing 600 gallons (5,120 pounds) of oil were injected into each of three shallow injection wells screened in the sand at a depth of 17-20 ft, and 230 gallons of the emulsion were injected into three deeper injection wells screened in the lower silt at 21.5-25 ft. Following emulsion injection, 50-150 gallons of additional native ground water were injected into each shallow/deep injection point to improve substrate distribution. The injections were completed over three days at rates of 4 gallons per minute (gpm) in deep wells and 7 gpm in shallow wells.

Cleanup goals were met within six months for all but one monitoring location directly downgrade of the asphalt-floored building. Additional substrate was injected in October 2003 to address the single shallow monitoring well exhibiting no changes in contaminant concentrations. Approximately 55 gallons of the same substrate were emulsified with 550 gallons of native ground water (a more dilute 1:9 ratio) and injected into each of four new shallow, direct-push injection points. Emulsion injections were conducted at a rate averaging 6 gpm with pressures of 13-18 psi, reaching a depth of 15-17 ft bgs. Each was followed by injection of 25 gallons of additional uncontaminated native ground water to improve substrate distribution.

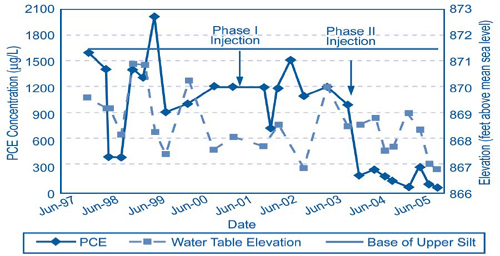

Within three months of the second round of injections, concentrations of PCE at the target well decreased approximately 80% and concentrations of cis-1,2-DCE, VC, and ethene increased substantially. Subsequent ground-water monitoring has shown temporal increases in PCE concentration, followed by temporal increases in TCE, cis-1,2-DCE, and VC. Monitoring also shows that the increases in contaminant concentrations are preceded by increases in ground-water elevation (Figure 2). These results indicate that more PCE mass has been degraded than originally estimated to exist in the saturated treatment zone, and that an unrecognized source of sorbed contaminant mass likely continues to release PCE to the aqueous phase during times of high water-table elevations.

Capital costs for the initial injections totaled $79,600, including $2,400 for vegetable oil substrate, and operating costs for both rounds of injections totaled $228,800. Due to the significantly high cost of continued ground-water monitoring in the area still exhibiting PCE concentrations above the state standard (5 µg/L), approximately 3,000 cubic yards of soil will be excavated and disposed offsite in 2008. Demonstration findings suggest that more complete site characterization would have resulted in more successful and rapid remediation of the entire site.

Contributed by Javier Santillan, AFCEE (Javier/santillan@brooks.af.mil or 210-536-4366), Donald Buelter, Former Newark AFB (don.buelter@afrpa.pentagon.af.mil or 210-925-3100), and Dan Griffiths (daniel.r.griffiths@parsons.com or 303-764-1940)

SERDP Study Identifies Subsurface Sampling Methods for Enhanced Decision-Making

The Colorado School of Mines (CSM) is conducting laboratory studies and mathematical modeling to develop improved methods for data collection from ground-water wells and soil cores used in remediation. Current work under this Strategic Environmental Research and Development Program (SERDP) project targets sites contaminated with chlorinated solvents, including those with DNAPL source zones. One element of this project quantifies measurement errors associated with methods for collecting soil-core samples used in analyses of organic contaminants. Early findings indicate that different methods for obtaining soil-core samples can lead to DNAPL concentrations varying by several orders of magnitude. Depending on the type of DNAPL organics and subsurface properties, these method differences may carry negative bias up to nearly 100%.

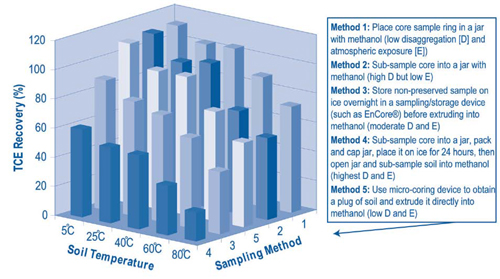

An informal survey of 18 remediation professionals provided insight into field practices, revealing that the most common method for subsurface soil sampling is to: scoop soil from a core into an empty sample jar, pack the contained sample to minimize headspace, cap it, store it at low temperature, and send it to an offsite laboratory for analysis. Results of the survey were used to design laboratory studies focused on five soil-sampling methods with different levels of media disaggregation and atmospheric exposure (MDE) and different susceptibilities to measurement error and uncertainty (Figure 3 inset).

These sampling methods were tested during collection of soil samples from water-saturated sand cores at soil temperatures ranging from those typical of ambient conditions across the U.S. to those following thermal remediation. The cores were spiked with TCE, PCE, or 1,1,1-TCA at varied concentrations.

Measured TCE concentrations in cores ranged from 20% to 112% of the known (48 mg/kg) concentration (Figure 3). Comparison of concentrations measured in samples collected using each of the five methods indicated significant differences and distinct trends based on soil temperatures as well as (simulated) field methods. The most accurate data were obtained at soil temperatures at or below 40°C using a sample collection method with low MDE. Analysis of PCE and TCA datasets revealed similar trends.

Preliminary study results indicate that use of low-MDE methods employing an extraction solvent in the field (Methods 1, 2, and 5) yields the most accurate and unbiased estimates of subsurface concentrations of chlorinated solvents. Though easy and historically most common, sample collection relying on cooled storage and next-day placement into methanol (Method 4) yields poor-quality data with high negative bias.

Soil samples yielding negatively biased data can result in underestimates of site-wide concentrations before and during remediation, potentially leading to errors regarding treatment efficacy. This potential can be amplified at sites where remediation causes a change in subsurface properties that in turn impact contaminant behavior such as changes in organic content or elevated temperatures. As shown in early site-specific studies, negatively biased data can lead to poor design of a remediation system as well as increased duration and cost of treatment.

Final results from these tests and follow-up investigation of additional DNAPL contaminants and concentrations, soil types and temperatures, and sampling methods, along with associated cost/benefit analyses, will be available from SERDP in 2008 (online at http://www.serdp.org).

Contributed by Robert L. Siegrist, Ph.D., CSM (siegrist@mines.edu or 303-384-2158), Ryan Oesterreich, CSM (roesterr@mines.edu), and Andrea Leeson, Ph.D., SERDP (andrea.leeson@osd.mil or 703-696-2118)

OSRTI Analyzes Trends in Superfund Cleanup Technologies

EPA's Office of Superfund Remediation and Technology Innovation (OSRTI) recently published the 12th edition of Treatment Technologies for Site Cleanup: Annual Status Report (ASR), which summarizes information from approximately 3,000 records of decision signed since 1982 for 1,536 National Priorities List (NPL) sites. This edition documents technology applications for more than 1,900 soil and ground-water cleanups, including 192 projects initiated in 2002-2005. To address increased use of containment remedies such as final cover systems (caps), the ASR now describes the state of this practice based on 112 cover systems at 89 NPL sites and 57 vertically engineered barriers at 55 NPL sites. The online version (at http://clu-in.org/asr/) also provides links to new downloadable spreadsheets containing key data used in the report.

State Coalition Reviews Remedies for Drycleaner Sites

The State Coalition for Remediation of Drycleaners (SCRD) reviewed data from drycleaning sites located across the U.S. to identify trends in remedial technologies used to treat soil and ground water. The SCRD is made up of the 13 states having programs devoted to remediation of contaminated drycleaning sites. With assistance from EPA’s Technology Innovation and Field Services Division, SCRD compiled a database of 116 drycleaning remediation projects within 15 states, of which 12 are member states. The database includes application-specific information such as site settings and history, geology and hydrogeology, soil and ground-water contaminant concentrations and distributions, remediation technologies, cleanup closures, and cleanup costs.

Of the 116 sites reviewed, 97 are drycleaning facilities that exclusively used PCE as a solvent, while 4 used petroleum-based solvents and 15 used both. Forty-four of the sites are located in Florida, and 55 were active facilities at the time of the study. SCRD identified several trends in the contamination found and the remedial actions conducted at the study sites:

- Soil Contamination and Remediation: Soil contaminants were detected at 106 sites, with PCE and its degradation products (e.g., TCE and DCE) found at 64 of these sites. Petroleum-related contaminants were the most common non-PCE-related compounds detected. Although petroleum solvents were used exclusively at 4 sites, spotting agents, detergents, fuel oil, and gasoline were potential sources of these contaminants at these and other sites.

Remediation was conducted in unsaturated soil at 100 sites using excavation/removal (44 sites); soil vapor extraction/passive venting, including multi-phase extraction (63); biostimulation (6); in-situ chemical oxidation (6); ZVI soil mixing (1); and a mobile-injection treatment unit (1). - Ground-Water Contamination and Remediation: Drycleaning-related contaminants were detected in ground water at all of the study sites. PCE was detected in ground water at 114 of the 116 study sites, including those using only petroleum solvents–likely the result of using PCE in spotting agents. PCE degradation products were detected at 107 sites. Presumptive evidence of PCE DNAPL, inferred by a PCE concentration of 1.5 mg/L or more in ground water, was found at 70 of the sites.

Ground-water remediation was conducted at 87 of the study sites. Of these, conventional pump and treat, air sparging, and multi-phase extraction were used at less than half, while innovative technologies were used at 63 sites: chemical oxidation (27 sites), bioremediation (26), recirculating wells (in-well sparging) (6), cosolvent/surfactant flushing (2), co-oxidation (1), and a ZVI PRB (1).

Together, chemical oxidation and bioremediation account for over 60% of the ground-water treatment systems and 73% (27 of 37) of the closed ground-water sites in the study. Only 1 of the 37 closed sites had employed pump and treat, and none employed multi-phase extraction, the second most common conventional ground-water system.

Of the 37 cleanup-closure sites, 23 were closed solely through soil remediation, and 13 required engineering and/or institutional controls. Total costs for cleanup, including assessment, remedial design/installation, monitoring and operation/maintenance, were available for 28 of the 116 study sites. The total project cost ranged from $46,200 to $1,662,000, and averaged $216,900. Study findings recognize that these estimates represent low-end costs for sites with limited contamination or low difficulty in remediating. SCRD recently published the results of the study in Comparison of Remedial Systems Employed at Drycleaners (http://www.drycleancoalition.org/download/site_profile_paper.pdf).

Contributed by Eric Cathcart, South Carolina Department of Health & Environmental Control (cathcaef@dhec.sc.gov or 803-896-6847), Bob Jurgens, Kansas Department of Health & Environment (bjurgens@kdhe.state.ks.us or 785-291-3250), and Bill Linn, Florida Department of Environmental Protection (william.linn@dep.state.fl.us or 850-245-8939)