- Sequential In-Situ Chem/Ox and ERD Treatment of Groundwater Destroys CVOCs

- Vegetable Oil Emulsion Promotes Contaminant Degradation in Bedrock Groundwater

- Benzene and Xylene Degradation Accomplished through Ozone Sparge Technology

- EPA Issues New Policy and Strategy to Reduce Environmental Footprints of Cleanup

- DNAPL Guidance

This issue of Technology News and Trends highlights innovative strategies for in-situ treatment of contaminated groundwater through subsurface injection of reagents to promote chemical oxidation (chem/ox) or biodegradation through enhanced reductive chlorination of contaminants.

Sequential In-Situ Chem/Ox and ERD Treatment of Groundwater Destroys CVOCs

Online Resources

CLU-IN's online area for vendor support offers tools to help technology developers and vendors advance innovative methods for using technologies such as in-situ chemical oxidation. The tools span product development stages ranging from bench-scale testing through full commercialization, and address business planning, marketing, financing, and related technical issues (www.cluin.org/vendor).

Five chlorinated volatile organic compound (CVOC) plumes originate from sources beneath degreasing areas at the former Pall Aeropower facility in Pinellas Park, FL. Chemical oxidants in the form of Fenton's reagent and potassium permanganate (KMnO4) and emulsified soybean oil as an electron donor were sequentially injected into the saturated zone to directly destroy contaminants and biodegrade them through enhanced reductive chlorination (ERD). After five years of injections and associated groundwater conditioning, monitoring of continuing source area ERD and plume attenuation continues.

Chloroethenes used at the site from 1972 to 1998 were the most abundant and widespread contaminants. Pre-remedial sampling detected trichloroethene (TCE) concentrations as high as 470,000 µg/L and tetrachloroethene (PCE) concentrations as high as 110,000 µg/L. Based on chemical solubilities, dense non-aqueous phase liquid (DNAPL) was suspected at four locations. The PCE and TCE daughter compounds cis-1,2-dichloroethene (cDCE) and vinyl chloride and eight additional VOCs also were present.

Numerous physical and chemical challenges were considered during remedy selection and design. For example, site soil varies considerably with depth. The upper 30-foot surficial aquifer consists of fine silica sand overlying silty, fine silica sand. A two-foot layer of clay and silt separates the upper silica soils from an underlying intermediate confining unit—layers of silty sand, bioclastic sand, and silt and clay that contain decomposed limestone and shell fragments extending to 100 feet below ground surface (bgs).

Varying flow rates of groundwater, which is encountered 3-4 feet bgs, also complicated the treatment strategy. Low hydraulic conductivity limits the annual groundwater movement to 8 ft/yr at 11-16 feet bgs, 2 ft/yr at 21-26 feet bgs, 10 ft/yr at 39-44 feet bgs, and 0.25 ft/yr at 65-70 feet bgs. Another challenge was the range of pH in background groundwater, which is around 5.5 in the surficial aquifer and between 7 and 8 in the intermediate aquifer.

The majority of CVOCs were found in the lower surficial aquifer (20-28 ft bgs, with groundwater flow rate of 2 ft/yr), where low hydraulic conductivity limits the recovery of groundwater and distribution of injected reagent solutions. Smaller quantities of CVOCs in the upper surficial aquifer (over 20 ft bgs, with 8 ft/yr)) and in the upper intermediate aquifer (30-50 ft bgs, 10 ft/yr) also required treatment.

The treatment strategy focused on in-situ destruction of DNAPL and the high concentrations of dissolved-phase CVOCs, which would most cost-effectively destroy contaminant mass and decrease dissolved-phase loading to the plumes. Natural attenuation is anticipated to reduce the sizes and concentrations of the plumes over time.

Chem/ox using Fenton's reagent was the first technology implemented based on its ability to destroy large masses of CVOCs in a short period of time. Implementation involved separate injections of 50% hydrogen peroxide solution and soluble ferrous iron salts. In the course of three events, approximately 18,000 gallons of solution were injected at a rate of 0.75-1.5 gpm in permanent treatment wells and direct push locations. The highest dissolved TCE concentrations were reduced 90% or more within three months. Levels then began to rebound as CVOCs desorbed from the soil, signaling the point to implement follow-on remedial technologies.

Since KMnO4 is a longer-lived chemical oxidant than Fenton's reagent, it was administered after the majority of DNAPL and high dissolved concentrations of CVOCs were depleted and the slow desorption of parent CVOCs had begun. Emulsified soybean oil, serving as an electron donor, and proprietary bacteria were injected to enhance and augment reductive dechlorination after chem/ox was complete. Additional solutions were injected to raise groundwater pH or increase nutrient concentrations in an effort to further enhance reductive dechlorination.

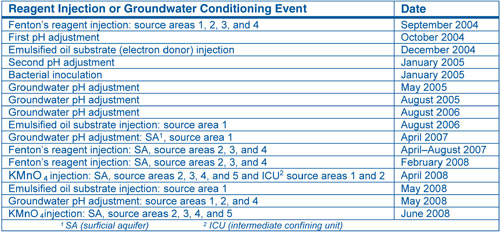

As of September 2009, 16 events involving reagent injection or groundwater conditioning had been completed (Table 1). A network of 216 permanent treatment wells screened over three depth intervals and 96 direct push locations have been employed. Potable water or very weak reagent solutions were typically injected last into each well to minimize inorganic and biological screen plugging. This technique allowed many treatment wells to be used ten times or more, although several wells were damaged beyond reuse (particularly during Fenton's treatment).

The Fenton's reagent produced a significant volume of reaction gases, particularly in lower portions of the surficial aquifer where groundwater flow rates are low and reagent doses were highest. The low soil permeability limited the spread of reaction gases and allowed pressure to build, forcing groundwater and reagent solutions upward along treatment well casings or injection tooling. Depending on the competence of building floors or pavement, liquids remained below grade or flowed onto the surface. Daylighted liquid was neutralized with a reducing solution.

Chem/ox also depressed pH of the groundwater to a sub-optimal level for reductive dechlorination. Groundwater pH was further reduced, in some cases to below 5.0, during reductive dechlorination due to the low buffering capacity of the surficial aquifer. As a result, approximately 3,000 pounds of potassium hydroxide and potassium bicarbonate (in solution) have been injected to raise the pH.

Naturally high aquifer temperatures averaging 75°F provided excellent conditions for ERD following chem/ox. Edible oil substrate (EOS) was injected in the form of soybean oil. One month after the initial EOS delivery, an anaerobic bacterial blend containing Dehalococcoides ethenogenes (DHE) was inoculated. Augmentation of the existing population of DHE, the only bacteria found to completely dechlorinate PCE to ethane, provided a low-cost method for significantly accelerating biodegradation. Over three events, approximately 65,000 pounds of EOS were injected.

During a June 2009 sampling event, 134 monitoring wells were sampled for 11 VOCs. Results indicated that the highest pre-treatment TCE concentration (470,000 µg/L) had decreased 99.9%, to 240 µg/L. PCE and cDCE in the same well had decreased 99.3% and 23%, respectively, while vinyl chloride concentrations increased 1,800%. Vinyl chloride concentrations in a monitoring well 120 feet downgradient were found to decrease from a post-treatment high of 1,200 to 310 µg/L, documenting shrinkage of the plume. Although concentrations of daughter compounds (which are more soluble than their parents) had risen for three to six months in some monitoring wells during the course of treatment, June analytical results indicated that total moles of PCE, TCE, cDCE, and vinyl chloride in most wells continues to decrease.

Review of the project to date shows that chem/ox was able to destroy DNAPL and reduce dissolved PCE and TCE concentrations to a greater degree than reductive dechlorination in the short term; however, desorption of soil-adsorbed CVOCs typically caused a rebound in contaminant concentrations after oxidants were consumed or dissipated. In contrast, ERD has continued to destroy contaminants one to two years after each EOS injection. Additional remedial technologies will be evaluated for achieving the final cleanup goals, due to the extended cleanup duration caused by production and subsequent degradation of less chlorinated daughter products during ERD.

Contributed by Simone Core, FL Department of Environmental Protection (Simone.Core@dep.state.fl.us or 813-632-7600), Farsad Fotouhi, Pall Corporation (Farsad_Fotouhi@pall.com or 734-913-6130), and Jerry B. Lisiecki, Ph.D., Fishbeck, Thompson, Carr & Huber, Inc. (jblisiecki@ftch.com or 616-464-3751)

Vegetable Oil Emulsion Promotes Contaminant Degradation in Bedrock Groundwater

ERD of CVOCs was implemented in 2007 within a fractured bedrock aquifer at Solid Waste Management Unit 87 (SWMU 87) of the former Naval Surface Warfare Center (NSWC) in White Oak, MD. Work focused on bioremediation of contaminant hot spots through injection of an emulsified oil substrate (EOS) containing commercial-grade vegetable oil directly into the bedrock aquifer, which required pneumatic fracturing to enhance distribution of the emulsion. The project was initiated on a field-scale test basis, and one year of quarterly monitoring showed successful results.

SWMU 87 is one of 120 remedial areas of concern that were identified after closure of NSWC White Oak in the early 1990s. The area encompasses three acres located 50 feet from a large creek within a steep valley. Site geology consists of coastal plain deposits over fractured metamorphic and igneous bedrock. Groundwater depth ranges from 15 feet bgs in low-lying areas along the creek to more than 25 feet bgs at higher elevations. The upper five feet of the fractured bedrock has been weathered to saprolite through which groundwater flows at a rate of 0.4 ft/day. Contaminants existed primarily in the saprolite surficial aquifer but some were detected in the bedrock aquifer. The primary contaminant of concern was PCE, which was detected in concentrations ranging from 9 to 120 µg/L, exceeding the 5 µg/L maximum contaminant level (MCL). TCE and cDCE also were detected at concentrations exceeding the site’s risk-based media cleanup goals, which were set at the 5 µg/L MCL for TCE and 70 µg/L MCL for cDCE.

Several rounds of vegetable-oil emulsion injections were previously performed successfully for bioremediation at NSWC; however, pneumatic fracturing was added to the injection process at SWMU 87 due to limited permeability of the saprolite. Based on information from the site investigations, remedial work targeted a 14,000-ft2 area at the depth of 15-35 feet bgs to treat groundwater in the bedrock aquifer. Prior to treatment, the aquifer was mildly aerobic, with an average dissolved oxygen concentration of 5 mg/L and an average oxidation/reduction potential of +240 mV. Pneumatic fracturing was performed to increase bulk permeability of the formation and dilate the existing fracture network within the weathered bedrock matrix, thereby increasing interconnecting fractures that would provide more contact between the injected carbon substrate and contaminants. High-pressure nitrogen was used to create fractures emanating at six 3-foot intervals in each of 45 30- to 45-foot boreholes that would be used for substrate injection.

Pneumatic fracturing followed by EOS injection was conducted from May 7 until June 3, 2007, using a fracturing/injection process that required less than three hours for each injection well. Pressures required to "break the formation" and initiate fracturing ranged from 60 to 700 psi, which indicated a very heterogeneous aquifer. The typical initial fracturing pressure was approximately 300 psi. Once the formation yielded to initial pressure, typically a few seconds later, the maintenance pressure required to continue fracturing decreased to 140 psi. At this pressure, nitrogen flowed into the formation at approximately 2,000 cfm for the duration of the pneumatic fracturing process. Sixteen intervals could not be fractured with pressures reaching 700 psi (the upper limit of safe operation of the pneumatic fracturing unit). This indicated competent bedrock rather than the targeted unit of saprolite. In addition to monitoring the nitrogen flow rates and pressure in fracturing wells, pressures in adjacent wells were recorded and associated ground heave was measured. Minimal ground heave occurred, with a maximum of 0.5 inches that occurred during initial fracturing and an average of 0.1-0.2 inches throughout the fracturing process.

Immediately following pneumatic fracturing, the emulsified oil substrate was pumped under low pressure (ranging from 35 to 250 psig) into each of the 45 boreholes. The average volume pumped into each interval of a borehole was 53 gallons of a 60% vegetable oil emulsion followed by 57 gallons of chase water. Since some intervals had not fractured, the balance of oil was pumped into adjacent intervals or injection wells to ensure the full target volume of 10,440 pounds was placed in the formation. Five existing monitoring wells located within 30 feet of the injection points were used to monitor substrate distribution and persistence and to assess treatment effectiveness over time.

Substrate distribution was immediately evident in adjacent injection wells through visual observation of the vegetable oil emulsion and measurements of elevated total organic carbon (TOC) in groundwater collected from monitoring wells. Field data from the first round of quarterly monitoring showed a significant TOC increase in all monitoring wells (indicating sufficient organic substrate was available for biological activity) and a dissolved oxygen increase from 2.5 mg/L to a maximum of 6.3 mg/L. A sharp decline in dissolved oxygen after six months of treatment, followed by a non-detect level after nine months, indicated that anaerobic biodegradation had occurred. Further evidence of biological activity included an increase in methane, soluble iron, and soluble manganese concentrations in all monitoring wells.

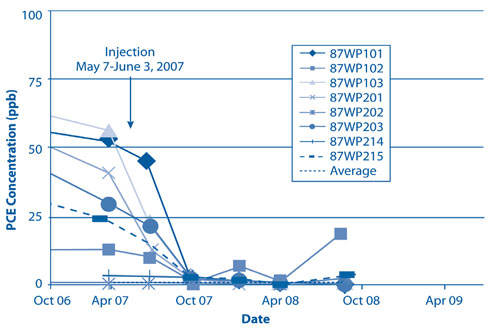

PCE concentrations in groundwater decreased to below 5 µg/L in all treatment-area wells within six months after the injection (Figure 1). Over the following year, notable rebound in contaminant concentrations was observed in two monitoring wells (87WP102 and 87WP202) located 40 feet downgradient and 20 feet crossgradient, respectively, of the treatment zone. Monitoring at the downgradient well closest to the creek (87WP103) indicated a steady decline in PCE concentrations and moderate increases in PCE daughter products after the injection, which suggested that PCE migration was not occurring.

Groundwater sampling data on PCE degradation products such as DCE and vinyl chloride indicated that PCE reduction by way of sequential dechlorination had occurred. Average DCE concentrations increased from approximately 1 µg/L to 23 µg/L during the first six months after the injection but decreased to 8 µg/L approximately 12 months later. cDCE remained relatively unchanged from an average of approximately 1 µg/L for the first three months after the injection but increased to 23 µg/L over the next three months. Concentrations of vinyl chloride reached 5 µg/L approximately one year after the injection, with a high of 17 µg/L in one well. Over the following 10 months, the average vinyl chloride concentration decreased to 0.6 µg/L, as concentrations of daughter-product ethene increased dramatically (315%); treatment well monitoring showed that dissolved-phase ethene concentrations peaked at 6.5 µg/L. Total CVOC concentrations averaged approximately 12 µg/L in August 2008, a 55% reduction from the pretreatment average of 30 µg/L.

Results from the last round of groundwater monitoring in August 2008 indicate that the average total CVOC concentration had continued to decrease due to natural attenuation, to approximately 55% of the concentration prior to the single EOS injection in 2007. Follow-up sampling to evaluate continued natural attenuation is scheduled for November 2009. Project costs to date total approximately $712,000, including costs for installing the 45 injection wells and two monitoring wells and performing pneumatic fracturing/injection at each injection well.

Contributed by Dave Steckler, U.S. Navy (david.steckler@navy.mil or 202-685-8056), Steven G. Kawchak (Shaw Environmental and Infrastructure Inc. (sgkawchak@shawgrp.com or 609-588-6349), and Michael Liskowitz, ARS Technologies

Benzene and Xylene Degradation Accomplished through Ozone Sparge Technology

A RCRA corrective action involving ozone sparging was undertaken in 2008 at a gasoline- and diesel-contaminated site in eastern Louisiana to remediate soil in a low-permeability formation. Sparging with ozone as an oxidant was selected over other in-situ chem/ox techniques because it was projected to meet cleanup goals within three to six months. Final performance results and follow-up monitoring indicated that cleanup goals were reached within three months, allowing complete shutdown of the system five months later.

The site is located in the City of Vidalia along the Mississippi River. In general, the site's upper 16 feet of soil consists of moist silty clay. In most of the 23 borings advanced at the site, saturated soil conditions were encountered at depths ranging from 4 to 16 feet bgs. Adsorbed benzene and xylenes were identified as the constituents of concern, with concentrations of 160 and 1,050 mg/kg, respectively. The site-specific Louisiana Risk Evaluation Corrective Action Program (RECAP) cleanup standards for benzene and xylenes in soil are 9.7 and 490 mg/kg, respectively. Residual constituents in groundwater were below the site-specific RECAP standards and therefore did not require further remediation. The target treatment area encompassed approximately 750 ft2, with no apparent free product in groundwater. Based on quantities of dissolved and adsorbed contaminants in the saturated zone and smear zone, the contaminant mass was estimated at approximately 100 pounds.

In contrast to applications typical of other in-situ chem/ox techniques, use of ozone gas as a subsurface injectant allows for continuous delivery of an oxidation agent. The sparge process involves injection of ozone gas into the groundwater through a microporous oxidation point placed below the water table. Injected ozone migrates outward and upward through the groundwater, initiating contaminant oxidation as it moves through the saturated region. Typical reaction byproducts include carbon dioxide, water, and inorganic chloride.

Ozone delivery to the subsurface typically involves use of an air compressor that pulls in ambient air and passes it through an oxygen concentrator. The concentrator removes ambient nitrogen and delivers 90% pure oxygen to the ozone generator after drying the air stream. The ozone generator uses a high-voltage electrical current to convert the pure oxygen to ozone at 6% concentration, by weight, of ozone. An additional air compressor is used to blend ambient air with the ozone, allowing the ozone to be injected into the subsurface at typical flow rates of 1-4 cfm and up to 10 cfm at pressures reaching 50 psi.

This mixture of air and ozone is injected directly into the groundwater through a series of oxidation points equipped with a microporous diffuser. A field programmable PLC-based controller with an interface panel viewer is used to control the manifold, allowing field personnel to enable and disable oxidation points, switch between ozone and oxygen injection, set lag time between sparge cycles, and set sparge duration, as necessary.

Calculation of the ozone mass required at the site considered inorganic compounds in groundwater that could act as oxygen receptors and potentially increase the demand for ozone during treatment. In the absence of these data, the anticipated ozone mass to be delivered was increased by 25%.

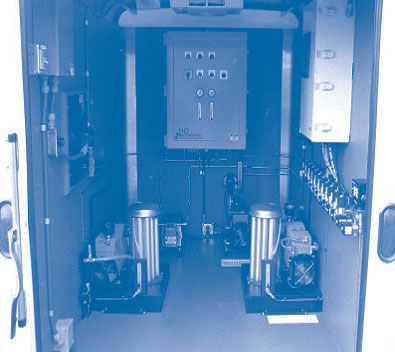

Sparging began in mid December 2008. Ozone was generated by a portable unit capable of producing up to 2.72 pounds of ozone per day (Figure 2). The ozone was delivered to the subsurface through 20 sequential injection points by use of a pump with a maximum delivery rate of 3.8 cfm at 50 psi. Nine 1-inch diameter oxidation points set approximately 16 feet bgs and positioned in a triangular grid were used to achieve a 10-foot radius of influence. The system was programmed to sparge ozone alternating between each oxidation point for 20 to 30 minutes cycles and then shut down for a 30-minute cool-down period before restarting the next cycle. All equipment was made of ozone-compatible material such as stainless steel, Teflon, Kynar, Viton, and schedule 80 PVC, instead of high-density polyethylene and natural rubbers that could easily degrade.

Soil samples taken after three months of ozone sparging indicated a benzene concentration of 0.57 mg/kg and total xylene concentrations of 44.9 mg/kg, a respective 99.6% and 95.7% reduction from pre-treatment concentrations. The ozone sparge system was shut down in March 2009 when an additional soil sampling event indicated that benzene and total xylene concentrations were below the site-specific RECAP standards. Demobilization and the plugging and abandonment of monitoring wells were conducted in August 2009, after confirmation soil sampling indicated successful remediation of benzene and xylenes. A "No Further Action" letter is anticipated, pending final approval of the data by the LDEQ.

Costs for installing the ozone sparge system and three months of operation totaled approximately $134,570, including $118,220 for equipment, installation, and startup expenses. The remaining project costs were allocated to three months of operation and maintenance, which averaged $5,450 each month and included $200 per month for utilities.

Contributed by Durwood Franklin, LDEQ (durwood.franklin@la.gov or 318-362-5439) and Charles R. Plummer, IMT, LLC (rickplummer@imtco.net or 318-325-1830)

EPA Issues New Policy and Strategy to Reduce Environmental Footprints of Cleanup

The U.S. EPA recently released its Principles for Greener Cleanups to improve the decisionmaking process for cleanup activities in a way that reduces adverse impacts of cleanups on communities (www.epa.gov/oswer/greencleanups). In light of the principles, EPA concurrently released a Superfund Strategy for Green Remediation to outline the Agency's actions and initiatives for reducing the footprints specifically at Superfund sites (www.epa.gov/superfund/greenremediation). The principles and strategy aim to reduce the environmental footprint by:

- Minimizing energy consumption and maximizing use of renewable energy

- Minimizing air pollutants and greenhouse gas emissions

- Minimizing water use and impacts to water resources

- Reducing, reusing, and recycling material and waste

- Protecting land and ecosystems

To help project managers and other stakeholders routinely apply the principles and strategy, the Agency is developing a series of fact sheets recommending best management practices for commonly used technologies such as soil vapor extraction, bioremediation, and ex situ treatment of groundwater. For more information about the practices, contact Carlos Pachon in EPA's Office of Superfund Remediation and Technology Innovation (pachon.carlos@epa.gov). The full range of environmental, energy, and economic aspects of green and sustainable remediation also will be addressed at the International Conference on Green Remediation to be held in Amherst, MA, in June 2010 (www.umass.edu/tei/conferences/).

The Interstate Technology & Regulatory Council (ITRC) offers a three-part series of guidance documents on in-situ bioremediation of chlorinated ethene DNAPL source zones. The series provides an overview of the issues, case studies, and a review of technical and regulatory considerations. To download the guidance, visit www.itrcweb.org/guidancedocument.asp?TID=47.