- Featured Articles

- Pilot-Scale Operation: Bacteria-Inoculated Limestone Treatment of AMD on National Forest Land

- Full-Scale Operation: Biochemical Reactor Treats ARD near Lake Shasta

- Remedy Optimization: ARD Treatment Plant Combined with Source Control at the Gilt Edge Mine

- Resources

- Interagency Website: Abandoned Mine Lands Portal

- EPA Website: Abandoned Mine Lands

- CLU-IN Website: Mining Sites

- EPA Reference Guide: Treatment Technologies for Mining-Influenced Water

- New Report: Operation and Maintenance of Passive Acid Mine Drainage Treatment Systems; A Framework for Watershed Groups

- Applied Research and Development: Passive Treatment of Mine Impacted Water in Cold Climates: A Review

- Upcoming and Recent CLU-IN Webinars: Mining Sites

Download This Issue in Adobe PDF® Format

Download This Issue in Adobe PDF® Format

(858KB/14pp/PDF)

This issue of Technology News & Trends highlights innovative approaches for remediating sites that are contaminated due to the presence of mining-influenced water (MIW) or solid waste associated with the mining of hard rock, coal or uranium. About 14,000 active and 500,000 abandoned mining sites are estimated to exist across the United States. Whether past or ongoing, mining operations can create a host of contamination issues, including the release of contaminants of concern such as arsenic, cadmium, copper, lead and zinc, into soil, groundwater and surface water. Much of the contamination is associated with acid rock drainage (ARD) that is generated when surface water or groundwater comes into contact with acid-generating mine wastes or with bedrock exposed by mining processes.

Federal partners such as the U.S. Bureau of Land Management (BLM), Environmental Protection Agency (EPA) and Forest Service are working with state agencies, tribes and other stakeholders such as watershed groups to find solutions for mining sites. EPA also is working with industry to identify cost-effective and low-maintenance treatment systems for mine site cleanups. Factors affecting selection of a treatment technology for a mining site commonly include the site's available land surface, topography, remoteness, access to power and other utilities, and climate regime. Other factors concern the treatment system's anticipated longevity, maintenance needs, flow rate and performance criteria.

EPA continues to foster broader restoration and reuse of mining sites. Rebuilding of plant and animal habitat, for example, enables ecological land reuse of mining sites and restores associated ecosystem services to a community. When aligned with the community's vision, development of renewable energy offers additional means for returning past mining sites to sustainable and beneficial use.

Pilot-Scale Operation: Bacteria-Inoculated Limestone Treatment of AMD on National Forest Land

Contributed by Mike Nicklow and Shiv Hiremath, Ph.D., U.S. Department of Agriculture Forest Service

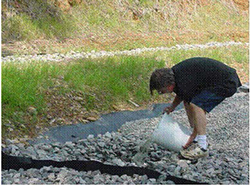

Figure 1. Surface of the underground limestone/microbial treatment system (in foreground) positioned upgradient of Kimble Creek

The Kimble Creek remediation site in the Wayne National Forest of southeastern Ohio is one of several abandoned coal mine sites responsible for acid mine drainage (AMD) pollution of ground and surface water in the region. Ongoing release of AMD with high concentrations of metals such as iron, aluminum and manganese and associated conditions such as high surface water acidity were found harmful to the aquatic life. In 2003, a pilot-scale remedy was constructed at the Kimble Creek site (Figure 1) to test performance and economics of an underground treatment system employing metal-oxidizing bacteria adsorbed onto limestone rocks. Based on its performance, the system was enlarged in 2005 to handle a higher rate of influent flow. Intermittent tests over the past nine years indicate the treatment system is functioning as expected.

The AMD became evident after a 1995 rainstorm, when orange-tinted water was observed in Kimble Creek and a fish kill occurred farther downstream in Pine Creek. Water samples from Pine Creek exhibited iron hydroxide precipitate, abnormal surface water chemistry and lack of normal stream fauna. A preliminary assessment and site inspection and an engineering evaluation and cost analysis (EE/CA) concluded that a 0.4-acre area within the former underground coal mine along Kimble Creek was partially filled with approximately 168,000 gallons of acidic water.

The EE/CA surveyed 14 removal action options and investigated three in detail: (1) mine dewatering with expanded flow diversion; (2) mine dewatering with limited flow diversion and bioaugmentation; and (3) an underground treatment system involving a microbiological treatment system known as the Pyrolusite Process®. The microbiological treatment system was selected due to its previous effectiveness at other sites, as well as potential technical difficulties in implementing the first two options. The system was designed by Wayne National Forest personnel over 10 months in 2002 with assistance from the Forest Service's Northern Research Station.

The project is located on a moderately steep, forested, southwest-northeast trending hill with three mining-related benches crossing the hillside. Three portals are known to exist in this area, and another portal may exist along the lowermost bench. All three portals drain into Kimble Creek, which ultimately flows into the Ohio River. Coal waste known as "gob piles" near or downhill from these portals contribute to the emerging AMD. The AMD crosses the bench and flows downhill through gob, consequently coalescing into a single flow path at the toe of the gob. Flow measurements showed that the water volume increases from the portal to the gob toe, indicating that subsurface flow through the gob is augmenting surface flow. The highest AMD flow measured at the toe to date is 15 gallons per minute (gpm).

The treatment system consists of a limestone bed inoculated with selected aerobic bacteria. As the bacteria grow on rocks, they etch away the limestone, releasing calcium carbonate that neutralizes the AMD acidity and oxidizes metals. Manganese removal under these conditions is achieved at pH 6 to 7; in contrast, other chemical treatment methods typically require a pH rise to 9.5. These conditions also enable removal of iron, a major component of AMD, as a dense, crystalline, low-volume oxide. Normally, iron in AMD precipitates out as a voluminous hydroxide (yellowboy) that easily clogs a treatment system. When pH increases, this technology also removes aluminum through abiotic processes.

Figure 2. Limestone emplaced in three lined, underground treatment cells at the Kimble Creek site

Use of limestone in the treatment bed offered the advantages of high calcium content, low cost, ease of use and formation of a dense, easily handled sludge as an end product. Expected disadvantages of using limestone included slow reaction time, loss in system efficiency due to coating of the limestone particles with iron precipitates, difficulty in treating AMD with a very high ferrous-ferric oxide ratio, and ineffectiveness in manganese removal. Introduction of microbes was anticipated to mitigate most disadvantages.

Construction of the treatment system began in March 2003 and was completed in two months. A conventional trackhoe was used to dig a trench approximately 50 feet wide, 15 feet long and 7 feet deep. The bottom of the trench was lined with a layer of synthetic, water-proof fabric that was baffled by PVC pipes to form three cells (Figure 2). A mini-excavator was "walked" into the cell to avoid liner damage and spread the material into areas exceeding the trackhoe reach. Each cell received approximately 500 cubic yards of limestone obtained from a local quarry. The cells also received approximately 1 cubic yard of rocks already exhibiting bacterial growth due to earlier inoculation. Six ports were installed for water and rock sampling.

Figure 3. Inoculation of bacteria solution into a port extending into limestone emplaced at the Kimble Creek site

Within days of completing construction, a mixture of five strains of metal-oxidizing bacteria was introduced to the limestone beds via buckets at each of six inoculation ports (Figure 3). One re-inocoluation of the same bacterial solution was performed at each port over the following 12 months.

The pilot-scale system was designed to treat an average AMD flow of 2 to 4 gpm. Pipes at the upgradient end of the treatment system collected the AMD. To achieve a "wave" of AMD flow through different depths of the limestone beds, AMD entered at the bottom of the first cell then passed through the remaining cells via pipes at the top and bottom of each cell. The water exited the system at the top of the third cell, on the northeast (downgradient) end of the treatment area. From there, the effluent traveled through a series of diversion pipes extending under two adjacent roads and ultimately to Kimble Creek for discharge. The limestone beds were annually flushed to collect accumulated sludge, which was stored in an adjacent aboveground cell for ultimate offsite disposal.

Two major changes were made to the treatment system during its first year of operation. Due to significant clogging in the influent pipe, an upgradient manifold was added to aerate the influent AMD and direct it to the top instead of the bottom of the first treatment cell. Also, after suboptimal bacterial growth was observed on the limestone at the ground surface, an upgradient vegetation-covered holding cell was installed to provide additional carbon sources that could provide more bacterial nutrients. This design aspect was not previously incorporated since the site is thickly vegetated.

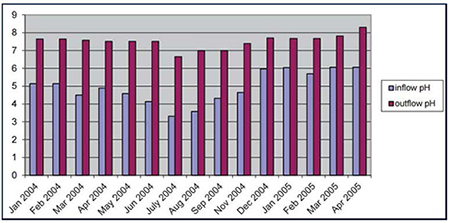

Figure 4. Influent and effluent pH at the Kimble Creek pilot-scale treatment system during its first year of operation

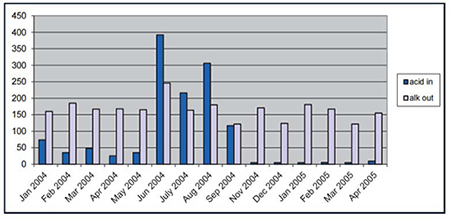

Determining the system's performance focused on evaluating pH and metal content of the influent and effluent, the bacterial growth and metal deposition on rock surfaces, and the sludge generated by the treatment process. Monthly sampling during the first year of operation indicated the system operated effectively. For example, effluent pH was significantly higher than influent pH during each sampling event, with an average pH increase of approximately 2 standard units (s.u.) (Figure 4). Also, acidity of the influent was almost completely removed through the treatment process (Figure 5). Concentrations of metals similarly decreased; for example, concentrations of aluminum (the second most common contaminant at this site) in the influent were as high as 100 milligrams per liter (mg/L) but decreased to almost non-detect levels in the effluent samples.

Figure 5. Acidity of influent (mg/L) and alkalinity of effluent (mg/L) samples in the Kimble Creek pilot-scale treatment system

Scanning electron microscopy and x-ray microanalysis were used to assess bacterial presence on the surfaces of rock samples taken from the limestone bed. Growth of the bacteria was estimated through spectrophotometric analysis to measure DNA concentrations in material scraped from the rock surfaces. The analyses consistently showed increases in density and growth of the inoculated bacteria, with no major variation due to seasonal changes.

Analysis of sludge samples indicated the presence of iron (predominantly in the ferric state, Fe+3), aluminum, and small amounts of zinc, magnesium and manganese. Due to the difficulty in quantifying ferrous iron (Fe+2) in solid samples, a colorimetric method was used to approximate Fe+2 and Fe+3 percentages. This method showed that approximately 90% of the iron was Fe+3, indicating the bacteria were effectively oxidizing ferrous hydroxides to the desired crystalline ferric form. Additionally, toxicity characteristic leaching procedure (TCLP) digestion analysis of the sludge samples indicated that hazardous constituents were below detectable levels, thereby allowing future disposal of the sludge elsewhere within the Wayne National Forest as nonhazardous solid waste.

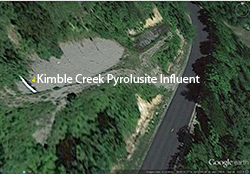

Figure 6. Recent aerial view of the 15-cell treatment system operating at the Kimble Creek site

In 2005, the pilot-scale system was replaced by a larger treatment system (Figure 6) capable of handling up to 15 gpm AMD. Limestone was removed from the three existing cells and 12 additional cells were constructed using the same techniques used earlier. The 15 treatment beds were inoculated and a drainage system was installed to divert clean surface water away from the treatment beds.

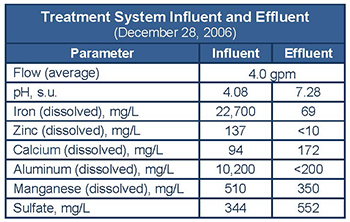

Influent and effluent sampling about 18 months later indicated that the treatment system continued to increase pH and decrease metal concentrations in the AMD (Figure 7). Based on the average flow, the enlarged system has effectively treated nearly 20 million gallons of AMD over the past nine years. Implementation costs to date total approximately $300,000, including $220,000 for the limestone bed, $20,000 for the bacterial inoculants, and $60,000 for monitoring over the first six years of operation.

Figure 7. Performance of the limestone/bacterial treatment beds at the Kimble Creek site, approximately 1.5 years after the system expanded to 15 treatment cells

Visual inspection in April 2015 revealed no ground-surface disturbance of the treatment system and a slightly higher rate of AMD inflow, likely due to high spring precipitation. Pending the availability of future funding, follow-up sampling and assessment of the system will be conducted to determine the need for any repair, flushing, modification, bacterial re-inoculation or sludge removal.

To learn more about this project, download the full paper, "Pyrolusite Process® to Remove Acid Mine Drainage Contaminants from Kimble Creek in Ohio: A Pilot Study"

Full-Scale Operation: Biochemical Reactor Treats ARD near Lake Shasta

Contributed by Brad Shipley, U.S. Department of Agriculture Forest Service, and James Gusek, Sovereign Consulting Inc.

Figure 1. Vintage World War II landing craft used for transport across Lake Shasta

The Golinsky Mine is an abandoned underground base metal mine in Shasta County, California, within the Shasta-Trinity National Forest. In 2010, a biochemical reactor (BCR) with a treatment capacity of 10 gallons per minute (gpm) was constructed to address onsite acid rock drainage (ARD). Construction of the BCR was significantly challenged by the site's remote location and rugged terrain as well as precipitation, which also influences the rate at which the BCR now treats ARD. The fully passive treatment system has functioned unattended since installation and is achieving approximately 95% metal removal and a more neutral pH. Projected longevity of the BCR media is approximately 20 years. Annualizing the $1.3 million construction cost, which was funded by the American Recovery and Reinvestment Act, over the total expected flow for two decades indicates a unit treatment cost of about 1.3 cents per gallon of ARD.

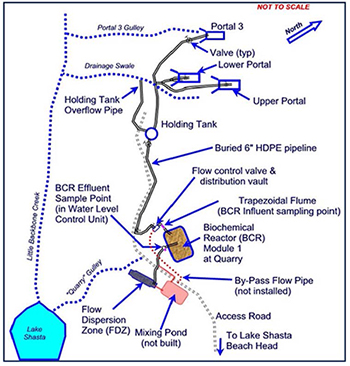

The Golinsky Mine was last active in the early part of the 20th century, when copper and zinc and small amounts of precious metals were recovered. The site comprises the mine as well as a milling and smelting complex situated in mountainous terrain. Access to this site is by boat (Figure 1), typically traveling three miles across Lake Shasta. Three former mine adits known as the Upper Portal, Lower Portal, and Portal 3 (Figure 2) exist. Concrete bulkheads were installed in 2001 at the upper and lower portals to flood the mine workings and suppress pyrite oxidation and ARD by perpetual submergence. Portal 3 indirectly connects to workings that are bulkheaded through natural fractures.

Figure 2. Schematic of BCR infrastructure at the Golinsky Mine

Geochemistry of the main mine ore, in workings of the Upper Portal and Lower Portal, is dominated by pyrite and other sulfides, which results in an ARD pool exhibiting a pH of 2.5 to 4 and containing metals such as iron, aluminum, copper, zinc, cadmium and manganese. Portal 3 reportedly exhibited ARD with a neutral pH and trace levels of metals prior to installation of the concrete bulkheads; however, the condition deteriorated soon after bulkhead construction and persisted until the BCR was installed and the main mine pool was drained down. The change was attributed to a rising level of ARD in the main mine pool, which induced ARD migration through natural fractures toward the Portal 3 workings.

In late 2003, Region 5 of the U.S. Forest Service investigated methods of treating and discharging the main mine pool water behind the two concrete bulkheads and to collect and treat ARD discharging from Portal 3. The measures aimed to improve water quality in Little Backbone Creek, a tributary to Lake Shasta. Passive treatment methods were preferable due to the site's limited access and lack of electricity and other infrastructure. Onsite bench- and pilot-scale testing (Figure 3) in 2003 indicated a BCR could effectively treat the ARD.

Figure 3. Bench-scale testing (left) and pilot-scale application of a BCR treating ARD at a rate of approximately 1 gpm (right) at the Golinsky Mine

Space to construct a full-scale BCR adjacent to the draining mine adits was insufficient due to very steep terrain. Therefore, it was constructed at a nearby abandoned limestone quarry. In 2004, a 1.5-mile-long pipeline was constructed to collect the ARD from the two bulkheaded adits and Portal 3 and deliver it by gravity to the quarry.

Figure 4. Barge delivery of sacks filled with organic media or other construction materials such as drainage gravel and rip rap needed for the Golinsky Mine BCR

During construction, high water levels in Lake Shasta caused by high precipitation in the spring necessitated use of a distant boat ramp, which added nearly six miles of cross-lake commute. Most construction equipment and materials were transported on a prefabricated barge (Figure 4). Construction materials were offloaded from the barge with a rented crane and transferred to a flatbed truck for the one-mile trip to the quarry. Due to limited quarry space, more than 2,000 fabric sacks of the imported materials were stored along an access road (Figure 5).

Similar to the pilot application, the full-scale BCR cell was configured as a vertical flow bioreactor with flow entering the top of the cell and flowing out the bottom. The BCR contains approximately 1,700 cubic yards (yd³) of organic media comprising rice hulls (10% by weight), wood chips (50%), hay (10%) and limestone (30%). This recipe was similar to the pilot recipe with the exception of using wood chips to save costs in place of organic matter purchased from a local biomass-fueled power facility. Approximately 4 yd³ of composted or fresh animal manure was tilled into the top six inches of the BCR media to provide the necessary initial bacterial community; experience in other BCR bench-scale tests suggested that such a relatively small amount could achieve the desired bacterial inoculation while minimizing the volume needing to be imported. About 2 yd³ of media saved from the pilot-scale BCR during its decommissioning was simultaneously tilled into the top soil to provide microbes that had already adapted somewhat to the site conditions.

Figure 5. Construction materials stockpiled along a quarry access road near the Golinsky Mine

The original design assumed that ARD from all three portals would be combined and treated in the BCR. In the intervening years between draining of the main mine pool (in concert with the 2004 pilot project) and commissioning of the full-scale BCR, the chemistry of Portal 3 water had improved enough that it did not require treatment. Additionally, the main mine pool had drained to the extent that the Upper Portal remained dry. As a result, the design was modified for BCR receipt of ARD only from the Lower Portal, which flowed at a rate averaging 10 gpm.

In October 2010, the organic materials and limestone were proportioned, mixed, and placed in the BCR trench, which was lined with 1.5-millimeter geomembrane (Figure 6). Diversion of the Portal 3 ARD to the quarry area also began at that time; due to its improved chemistry, that ARD was used for fire suppression, dust control on haul roads, and moisture control in earthwork fill placement.

Figure 6. Placement of media in the Golinsky Mine BCR

Commissioning of the BCR was anticipated to involve filling it with a mixture of Portal 3 and Lower Portal ARD that would allow bacterial incubation to commence. During the last week of construction and the following two weeks, however, the site received approximately 11 inches of rainfall that filled the BCR. The startup procedure was consequently modified to include addition of Epsom salt and agricultural gypsum. Sampling indicated that sulfate concentrations in the influent rebounded within two months, enabling the microbial community to begin the sulfate reduction process.

The BCR effluent flows via gravity into either of two flow dispersion zones (FDZs). Each FDZ consists of an unlined percolation trench equipped with a series of standard flow infiltration chambers, which are commonly used in residential septic systems. Although a single FDZ was initially used, frequent backup of the BCR effluent prompted construction of a new FDZ to fully handle the design flow rate of 10 gpm. The original FDZ, which was found to include a thin soil layer that limits effluent infiltration into underlying bedrock, now serves as an auxiliary system to handle excess from higher flow rates or other temporary conditions. Based on sampling results and observations during the pilot-scale operations, the infiltrated BCR effluent generally follows subsurface bedrock fractures or runs along the bedrock-colluvial contact before mixing with and becoming indistinguishable from other subsurface drainage that may periodically surface within an unnamed ephemeral tributary to Little Backbone Creek, near its confluence with Shasta Lake.

Figure 7. Progression of revegetation above the Golinsky Mine BCR, at three months after construction completion (left) and four years later (January 2015, right)

Germination of vegetation from seed in the hay component of the media occurred soon after the onset of inclement weather in the following autumn. Within five years, willows up to 16 feet tall and other plants had colonized the BCR surface (Figure 7). This vegetation may be suppressed in the future if oxidizing micro-environments in the root zone are found to suppress sulfate reduction.

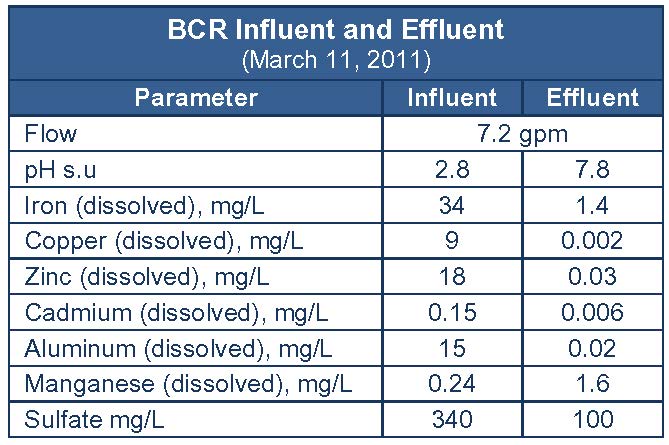

Figure 8. Observed flow and chemistry of ARD entering and exiting the Golinsky Mine BCR four months after its commissioning

The BCR was designed to provide an ARD residence time of about nine days at the design flow rate. Semiannual monitoring demonstrates consistent water quality in BCR effluent, with a pH rise from approximately 4 to 6.5 and significant removal of metals (Figure 8), with the exception of manganese. Experiences at other sites indicate that BCRs typically do not remove manganese and that naturally-occurring manganese in the organic substrate is commonly mobilized (rinsed) from the substrate, especially at startup. The mobilized manganese is likely deposited as manganese oxide (known as "desert varnish") on the rock surfaces in and adjacent to the FDZs. Trace levels of other metals that elude removal in the BCR are expected to adsorb to these rock surfaces, providing additional passive polishing of the BCR effluent.

The BCR has required no maintenance over the five years of operation. During storm events, the pipeline used to collect ARD at the Lower Portal has experienced some scaling and clogging by sediment. Flanges were installed on the pipes to allow easier and speedier cleaning when needed, which has occurred twice to date. Also, some scaling in the inlet flume box has slightly impacted accuracy of the pressure transducer used for continuous flow measurements.

Due to the prevailing drought in California, adit drainage has completely stopped from late spring to early fall during the past three years. The near stagnant conditions appear to have no measurable effect on water chemistry or metal removal within the BCR. Low or no flow of adit drainage under the anoxic conditions existing in the BCR may result in a low rate of cellulosic bacteria degradation of the organic matter, potentially increasing longevity of the BCR.

Remedy Optimization: ARD Collection and Treatment Combined with Source Control at the Gilt Edge Mine

Contributed by Joy Jenkins, U.S. EPA Region 8

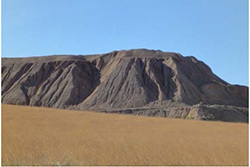

Figure 1. Aerial view of Gilt Edge Mine Superfund site

Cleanup at the 360-acre Gilt Edge Mine Superfund site in the northern Black Hills of South Dakota involves an acid rock drainage (ARD) collection and conveyance system and a water treatment plant that has operated since 2000. The most significant ARD source in 2000, when the site was listed on the National Priorities List, was the Ruby Mine Waste Dump left behind by past mining activities. Re-grading and capping of the former dump was completed in 2006. In 2016, significant earthwork will begin addressing ARD sources remaining within the primary mine disturbance area, which includes acid-generating waste rock and fills, spent ore, exposed acid-generating bedrock in mine pit highwalls and sludge (Figure 1).

A recent five-year review and optimization study indicate that the treatment plant, which uses a lime-based precipitation process, operates effectively. The review also confirmed that the planned ARD source control work should significantly reduce the volume of water requiring treatment in the future. Current optimization activities focus on reducing the cost of operating the treatment plant and preparing for future earthwork that prevents precipitation and runoff from contacting ARD-generating material. Additionally, plans for site drainage structures were recently modified to accommodate updated predictions of severe storm events at this site.

Figure 2. Spent ore from the cyanide heap leaching process formerly used at the Gilt Edge Mine

The contaminants of concern in surface water, groundwater, soil and sediment include metals (arsenic, cadmium, chromium, copper, lead, nickel, silver, thallium and zinc) as well as sulfate contributing to total dissolved solids. Cyanide and nitrates were a concern for a time after termination of the mining activities, which included a cyanide heap leach process (Figure 2) and rock blasting to extract gold and silver ore. Sampling indicated that the source of these contaminants was eliminated when active mining ceased.

The rate of ARD generation at this site varies considerably, due to variable precipitation rates influenced by orographic effects as well as regional weather patterns. For example, in 2012 and 2013 the site received approximately 19 inches and 49 inches of precipitation, respectively. Hydrologic modeling indicates that each inch of precipitation at this site generates approximately 34 million gallons of ARD requiring treatment.

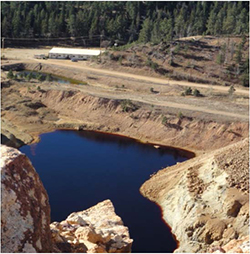

Figure 3. Addition of lime to high density sludge treated at the Gilt Edge water treatment plant

To reduce migration of metals and acidic water to streams, the ARD seeps and surface water runoff are collected and conveyed to the water treatment plant. The plant's lime-based precipitation process (Figure 3) is capable of accommodating a flow of about 325 gallons per minute (gpm). Collected ARD exceeding this capacity is stored in onsite impoundments, including former mine pits. Treated water is discharged onsite to Strawberry Creek. The cost to collect and treat the ARD ranges from $2 million to $2.4 million per year.

The treatment plant and site are staffed 24 hours per day, with a minimum of two operators to operate and monitor the ARD collection and conveyance systems and water treatment plant. Full-time staff also is needed to address potential problems such as storm-related power outages that could result in release of untreated water. The optimization study recommended installation of upgraded equipment enabling remote operation and monitoring of the treatment plant, which could eliminate the need for nighttime staff. The upgrades would include a supervisory control and data acquisition (SCADA) system, additional alarms and call-outs, pumps operated on level indicators and auto-start generators. Conversion to a fully automated water treatment plant is expected to cost approximately $500,000. The study also recommended short-term operation in a batch rather than a continuous treatment process to reduce staffing needs.

As of May 2012, when the optimization study was conducted, 12 million gallons of high-sulfate ARD and 4.1 million gallons of low-sulfate ARD were stored in the onsite impoundments, which have a total capacity of 253 million gallons. Under the current ARD-generating conditions and average annual precipitation (29 inches), the treatment plant would need to operate approximately 200 days per year at a rate of 325 gpm to treat the ARD volume generated each year. Completion of the future earthwork is expected to reduce ARD generation more than 67%. Based on these findings, the study estimated that the treatment plant could operate fewer than 70 days per year in the future.

Figure 4. The Strawberry Creek pumping station, one of three primary facilities for water management at the Gilt Edge Mine

Approximately $315,000 were saved in 2012 due to a modified operating plan involving a four-month suspension in treatment plant operations and in staffed overnight monitoring. In 2013, approximately $102,000 were saved through this approach; the operations and monitoring suspensions were held to 1.5 months due to the higher than average precipitation. An additional $26,400 savings was achieved in 2013 as a result of reducing water-sampling frequency (from weekly to monthly) at surface water locations with a long history of sampling.

Additionally, a previous energy audit revealed measures that could reduce electricity usage and costs. Post-audit modifications included installing a lower-power pump for handling discharge at the Strawberry Creek pump house (Figure 4) and installing a bladder tank and smaller pump for delivering process water from the treatment plant. Also, the electricity purchasing rate charged by the utility provider was negotiated to a lower rate. These changes resulted in approximately $37,000 in electricity savings per year.

Figure 5. One of two onsite pits holding high-sulfate water at the Gilt Edge Mine site

Prior to the upcoming earthwork, approximately 14 million gallons of high-sulfate water stored in two pits (Figure 5) will require processing in the water treatment plant. During processing, the mixing of high-sulfate water with treatment lime generates gypsum that forms a cake that tends to clog the multi-media filters, the final treatment component. Recent test-scale operations suggest that slowing the treatment flow to 100 gpm enables precipitation of the gypsum in the system's clarifiers, thereby reducing burden on the multi-media filters. Slowing the treatment rate would therefore allow the pit water to be more efficiently treated in the treatment plant and avoid the alternate pre-treatment approach of adding lime to the pits, which would generate additional sludge.

In the Ruby Mine Waste Dump capping area, the waste rock was re-graded in place in the upper portion of Ruby Gulch prior to cap construction. The composite cap consists of an impermeable low-density polyethylene liner placed directly above the waste rock. A layer of crushed rock serving as a protective layer above the liner is covered with approximately three feet of clean soil; the soil and rock were sourced from excess materials at a nearby highway construction project. In the topsoil, a mix of native prairie grasses such as wheatgrass, fescue and clover were seeded to promote re-vegetation. The capping system includes a complex series of lateral drainage structures that divert runoff water to uncontaminated drainage ditches and limit infiltration and prevent erosion of the cap (Figure 6). The cap is inspected periodically to assure its integrity; no significant erosion problems have been identified to date.

Figure 6. Five uppermost slopes and drainage channels along the capped Ruby Gulch waste repository, approximately three months after seeding

Approximately three years after cap construction, more work was initiated to further reduce or eliminate surface water infiltration into the capped waste repository, which was found to receive water leaking from the drainage ditches. Certain ditch sections were sealed through pressurized concrete grouting, and other ditch sections were lined with impermeable geomembranes. Approximately 3,200 linear feet of ditch have been grouted, and 660 linear feet of ditch have been lined. Two smaller repairs will be completed during the planned source control earthwork.

The earthwork will involve excavating and consolidating mine waste throughout the 290-acre disturbed area into three open mine pits. The pits will be backfilled with waste and covered with impermeable caps consisting of clean soil and vegetation, similar to the Ruby Mine Waste Dump cap. Newly exposed soil will be amended with lime to neutralize accumulated acidity and then vegetated. The earthwork also will involve grading to convey clean surface water throughout the site toward the historical (pre-mining) path of Strawberry Creek. Additionally, a lined water management facility will be constructed to handle the site's ARD in the future, rather than continuing to use mine pits that allow waste communication with groundwater. During years with an average amount of precipitation, these efforts are anticipated to reduce the annual ARD generation from 97 million gallons to approximately 30 million gallons. ARD due to groundwater-waste interaction in the bottom of the Ruby repository (as well as the "Dakota Maid" pit), however, is anticipated to continue.

To account for updated predictions of precipitation frequency and intensity at this site, including those concerning potential climate change, the drainage structures planned in the earthwork design were modified to sustain 7.3 inches of precipitation within a 24-hour period. This specification is based on the most recent projections from the National Oceanic and Atmospheric Administration, which estimates that 7.04 inches of precipitation within a 24-hr period at this location have a 1% chance of occurring in any given year, which constitutes a 100-year storm. In contrast, 4.3 inches of precipitation in a 24-hour period was the predicted 100-year storm taken into consideration during initial remediation activities. The 4.3-inch/24-hour scenario is now considered a 25-year storm, with a 4% chance of occurring in any given year.

RESOURCES

Interagency Website: Abandoned Mine Lands Portal

The Abandoned Mine Lands Portal serves as an information repository about abandoned mine lands (AML) and their associated environmental, health and safety issues, with a focus on federal, state, local and tribal efforts in AML cleanup and reclamation. This website provides links to key guidance and technical resources concerning a range of AML topics such as voluntary cleanup under EPA's Good Samaritan Initiative, bat protection, innovative cleanup or reclamation technologies, greener cleanup strategies and leverage of renewable energy development. The portal also provides links to numerous case studies developed by BLM, EPA, or the National Park Service.

EPA Website: Abandoned Mine Lands

EPA's Abandoned Mine Lands program identifies ways to protect human health and the environment by using all of the non-regulatory and regulatory approaches available to the Agency. These approaches include voluntary cleanups, Agency-managed emergency responses, involvement of brownfield partners, integration of site cleanup with site redevelopment/revitalization, listing on the National Priorities List (NPL) and enforcement activities. The Abandoned Mine Lands website offers news about mine sites and provides links to selected resources.

CLU-IN Website: Mining Sites

This website provides information on site characterization, cleanup technologies, and revitalization and reuse of mining sites, whether abandoned, closed, or active. Cleanup technologies addressed in this resource are categorized by their applicability to solid waste, MIW or both. This website also provides links to upcoming Internet seminars, workshops or conferences concerning mining sites and to archives of past seminars, videos and courses on related topics.

EPA Reference Guide: Treatment Technologies for Mining-Influenced Water

This report (EPA 542-R-14-001) focuses on cost and maintenance reductions that may be attained through passive treatment or through recently developed technologies utilizing hybrid passive-active treatment. It provides detailed information on 16 technologies identified through review of technical literature or by subject matter experts. For each technology, the report summarizes the treatment process, system operation, applicable contaminants, scale of implementation, long-term maintenance requirements, limitations, costs and effectiveness.

New Report: Operation and Maintenance of Passive Acid Mine Drainage Treatment Systems; A Framework for Watershed Groups

Recognizing that funding for AMD treatment is limited, the West Virginia Department of Environmental Protection recently compiled this report as a framework for encouraging watershed groups to develop operation and maintenance (O&M) plans for their passive treatment projects. The framework addresses institutional practices supporting O&M; O&M considerations through the project life cycle; best management practices (BMPs) for AMD remediation; post construction inspection, monitoring, and operation; and post-construction major maintenance. Particular BMPs discussed in this report include settling ponds and aerobic wetlands, anoxic limestone drains, anaerobic vertical flow wetlands, self-flushing limestone leach beds and steel slag beds.

Applied Research and Development: Passive Treatment of Mine Impacted Water in Cold Climates: A Review

The Yukon Research Centre of Canada recently evaluated the challenges encountered and the adaptations required to successfully use passive treatment systems for MIW in cold climates. The primary challenges concern a mining site's typically remote location, limited access in winter, freezing pipes, variable seasonal flow, and low productivity of microbial and macrophytic communities. Many adaptations have been implemented to address these challenges, such as pipe burial to avoid hydraulic failure, pipe insulation to avoid freezing surface waters, bypasses and overflows to maintain constant flow, summer establishment of microbial and macrophytic communities, and addition of liquid carbon sources to offset reduced organic matter decomposition in cold temperatures.

Upcoming and Recent CLU-IN Webinars: Mining Sites

EPA's Office of Superfund Remediation and Technology Innovation is presenting a series of webinars dedicated to the topic of mining sites. Recent events for which archived materials are available on CLU-IN include a June 4 webinar about remedial action, remedy performance and long-term land management at the Anaconda Smelter NPL site in Montana, and May 19 and May 20 webinars on "Mine Tailings Fundamentals: Current Technology and Practice for Mine Tailings Facilities Operations and Closure." Archives of previous webinars in this series can be viewed at www.cluin.org/mining under Training and Events. On June 18, 2015, the Interstate Technology and Regulatory Council will hold a CLU-IN webinar on Biochemical Reactors for Treating Mining Influenced Water.

Contact Us:

Suggestions for articles in upcoming issues of Technology News and Trends may be submitted to

Linda Fiedler via email at fiedler.linda@epa.gov.

Past Issues:

Past issues of the newsletter are available at http://www.clu-in.org/products/newsltrs/tnandt/.

Archives | Subscribe | Change Your Address | Unsubscribe