Green Remediation Focus

Travis Air Force Base

Solano County, California

NPL, RCRA, Federal Facility

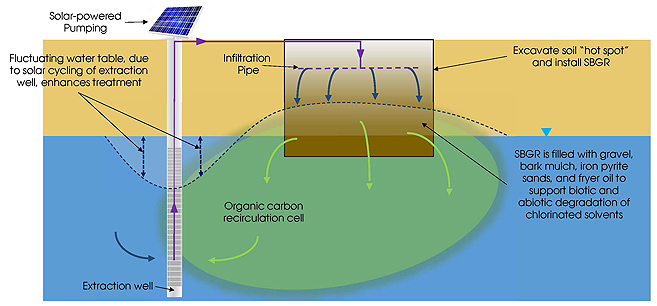

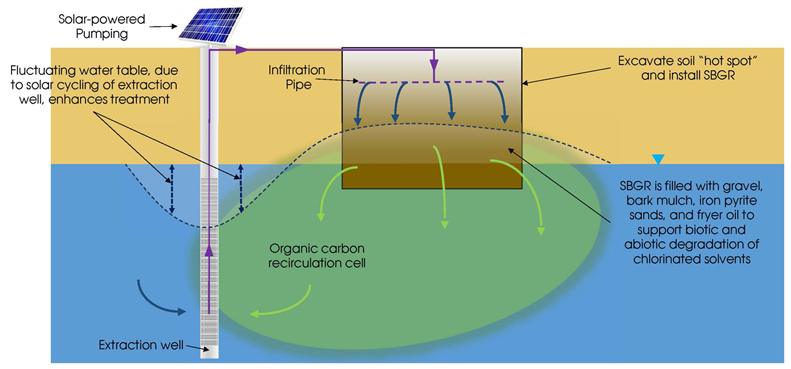

Cleanup Objectives: Treat groundwater plumes containing fuel and chlorinated solvents at this 6,000-acre active facility located between San Francisco and Sacramento, California. Environmental remediation at Travis Air Force Base involves 23 contaminated groundwater sites with over 700 monitoring, extraction and injection wells. Remediation technologies implemented to date include groundwater extraction and treatment at one of three on-base plants, subgrade biogeochemical reactors (SBGRs), enhanced bioremediation through emulsified vegetable oil (EVO) injections, and phytotechnology.

Green Remediation Strategy: The strategy's primary focus is reduction of greenhouse gas (GHG) generation, as part of compliance with the U.S. Department of Defense Consideration of Green and Sustainable Remediation Practices in the Defense Environmental Restoration Program guidance. Environmental footprint analyses were performed to quantify footprints and potential footprint reductions applying to remedy selection; remedy design and implementation; operation, maintenance and monitoring; and remedy optimization. The ASTM Standard Guide for Greener Cleanups (E2893) was used to prioritize best management practices (BMPs) expected to reduce the environmental footprint. High-priority BMPs implemented to date include:

- Using renewable energy generated from onsite resources to fully or partially power remediation equipment.

- Switching to less energy-intensive technologies for remediation polishing as contaminant concentrations decrease over time.

- Procuring local personnel and local vendors, to minimize transportation-related contributions to the footprint.

- Shipping remediation materials through bulk transportation methods rather than dedicated trucks.

- Using the nearest offsite facilities for disposal of waste.

- Reclaiming treated water for onsite use or storage.

- Avoiding use of potable water to irrigate plants installed for remediation or restoration purposes.

- Choosing environmentally friendly materials in place of potentially toxic chemicals as substrates for enhanced bioremediation.

- Choosing sustainably produced remediation products.

- Using industrial or commercial waste as reactive substrates in remediation components such as SBGRs.

- Reusing or recycling reclaimed construction materials such as asphalt and concrete demolition rubble.

Results:

Energy Conservation and Renewable Energy

- Reduced installation-wide electricity usage by an estimated 790,000 kilowatt hours of electricity per year (kWh/yr) (or equivalent energy) by optimizing remedies already in place and choosing remedial options anticipated to have a lower environmental footprint. For example, U.S. EPA Region 9 collaborated with Travis Air Force Base in conducting a detailed Site DP039 environmental footprint analysis to facilitate evaluation of four potential remedies for a chlorinated solvent source area and plume.

- Reduced energy demands of the "North Groundwater Treatment Plant" (NGWTP), alone, by an estimated 158,000 kWh/yr, by reconfiguring treatment strategies for groundwater in three areas where contaminant concentrations were lowered. Groundwater extraction at one area, Site LF007C, is now powered by an off-grid photovoltaic (PV) array that enables an extraction rate averaging 3 to 4 gallons per minute (gpm) 24 hours per day when the vernal pool is not present. The extracted groundwater is treated in a small, dedicated GAC system rather than thermal oxidation at the NGWTP. Contaminated groundwater at two additional sites originally supported by the NGWTP (Sites FT004 and SD031) is now treated through monitored natural attenuation.

- Avoiding use of approximately 70,000 kWh/yr of grid electricity to power pumps that recirculate contaminated groundwater through four SBGRs addressing contaminant source areas. Three of the SBGRs are equipped with off-grid, PV arrays that power recirculation pumps during daylight hours. The fourth SBGR (at Site SD034) uses a pulsed pumping strategy across six separate extraction wells, which creates a "washboard effect" at the capillary fringe for treatment of residual petroleum hydrocarbons. This approach uses less energy than a continuous pumping strategy.

- Avoiding use of approximately 17,5000 kWh/yr of grid electricity to recirculate contaminated groundwater through a 2.6-acre phytoremediation area. Groundwater recirculation is achieved through use of two 1-hoursepower submersible pumps powered by a small off-grid PV array.

- Avoiding use of approximately 35,000 kWh/yr of grid electricity by using solar energy to operate P&T equipment at Site ST018 as part of a RCRA corrective action addressing MTBE contamination. Off-grid PV panels fully power four 1-horsepower submersible pumps.

- Minimizing fuel use associated with offsite waste disposal, when needed, by choosing the nearest facilities. The nearest hazardous waste facility is located approximately 230 miles from the site, while the nearest landfill for nonhazardous waste is located approximately 7 miles from the site.

Air Quality

- Reduced total carbon dioxide emissions by approximately 930 tons per year as of 2019, when compared to 2008 remediation-related emissions, through the various installation-wide remedy optimization activities.

- Avoiding monthly generation of approximately 138,000 pounds of carbon dioxide through reduced consumption of grid-supplied electricity and natural gas to operate equipment used to treat extracted groundwater.

- Reduced overall GHG emissions by approximately 75% as of 2019, when compared to 2008 emissions, through use of the two solar energy systems and discontinued treatment operations.

- Reducing GHG generation through use of rail lines rather than trucks to deliver bioremediation liquids whenever possible. Available studies indicate that locomotive engines meeting Tier 4 emission standards produce approximately two-thirds less GHG than typical truck engines.

Water Preservation and Reuse

- Using treated water from Site FT005 rather than utility water to prepare EVO substrate for injections and subsurface biobarriers. The substrate is typically mixed onsite, using a 4 percent by volume solution of commercial-grade vegetable oil and water. When injected, the substrate is administered via hydraulic pressure within the treated water line rather than additionally pumped.

- Reusing over 160,000 gallons of the water treated at Site LF007C to replenish water levels in a small, on-base recreational lake.

- Using the solar-powered groundwater recirculation system as a source of water that can infiltrate the root zone of plants in the phytoremediation area, which comprises 400 red ironbark eucalyptus trees.

Material Conservation & Waste Reduction

- Used approximately 250,000 pounds of EVO between 2015 and 2019 as a substrate for enhancing bioremediation in groundwater plume hotspots or as biobarriers. The vegetable oil was made from soybeans grown by agricultural producers using water-conservation practices.

- Reused or recycled approximately one hundred 275-gallon intermediate bulk containers containing the EVO substrate.

- Obtained more than 1,000 cubic yards of gravel from a nearby quarry to install SBGRs at Sites DP039, SS016, SD031, FT004, SS014 and SD034. Additionally, bark mulch from local farms was incorporated into the SBGRs at Sites DP039, SS016 and FT004.

- Integrated more than 800 gallons of fryer waste oil supplied by the base's restaurants as a carbon-rich component of the SBGR at Site FT004.

- Used approximately 20 cubic yards of recycled drywall as construction material for one SBGR intended to support sulfate-enhanced biodegradation of fuel-contaminated groundwater. Monitoring indicates that the SBGR has reduced petroleum hydrocarbon concentrations in the source zone by an estimated 99 percent.

Property End Use: Continued use as a farm equipment maintenance facility.

Point of Contact: Nadia Hollan Burke, U.S. Environmental Protection Agency, Region 9

For more information, view Travis Air Force Base: A Greener Cleanups Case Study. Gamlin, J., D. Downey, P. Favara, L. Duke and G. Anderson. 2017. Remediation Journal. 27:9-17. [available through subscription or with non-subscription fee]

Update: April 2020