Green Remediation Focus

Lawrence Aviation Industries

Port Jefferson Station, New York

Superfund Removal & NPL

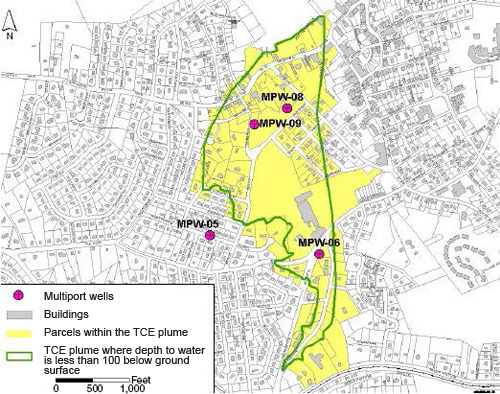

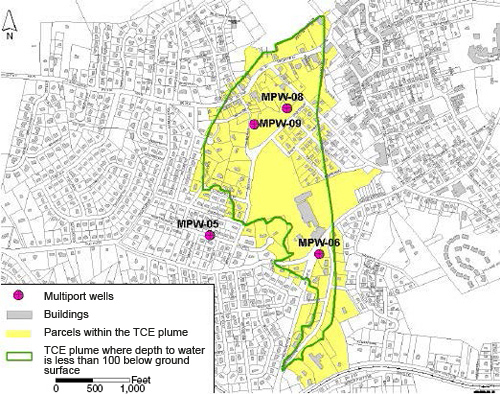

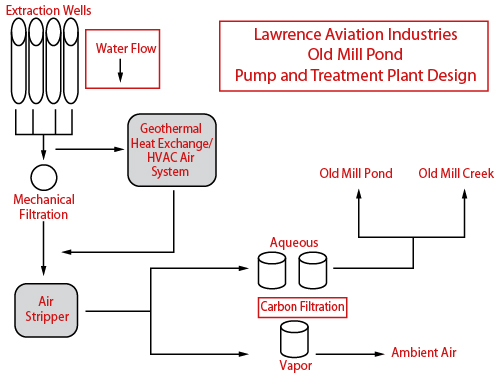

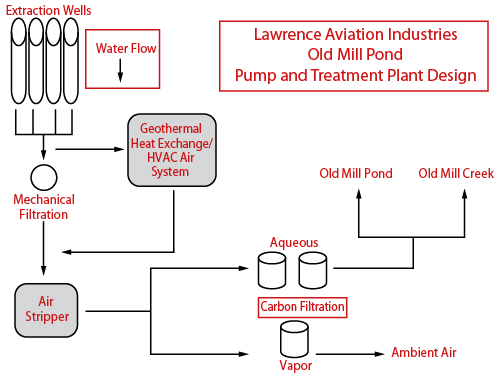

Cleanup Objectives: Remediate groundwater and soil contaminated by volatile organic compounds (VOCs) and polychlorinated biphenyls (PCBs) at and downgradient of this former titanium-sheeting manufacturing facility, which occupies 126 acres near the Long Island Sound. Removal and remedial actions have involved excavation and offsite disposal of PCB-contaminated soil followed by groundwater extraction and treatment through air stripping at two treatment plants; an onsite plant treats the contaminant source and an offsite plant (approximately one mile downgradient within the Village of Port Jefferson) treats a contaminant plume. (View EPA's 6-minute video, Green Remediation at Lawrence Aviation Site below.)

Green Remediation Strategy: The strategy focuses on: (1) using onsite renewable energy and maximizing energy and material efficiencies in the groundwater treatment process, (2) purchasing energy-efficient and environmentally friendly materials and products to construct the treatment plants, and (3) maximizing site-wide efficiencies to conserve water, energy and other natural or processed resources. For each water treatment plant, best management practices (BMPs) involved:

- Minimizing heat loss and undesired temperature-related expansion or contraction in the groundwater extraction wells by: (1) using steel rather than plastic pipes, (2) thermally fusing all pipe connections, (3) assuring full seals by packing each well with 20% bentonite slurry along its full length (up to 250 feet below ground surface (bgs) at the onsite facility and 80-140 feet bgs at the downgradient facility), and (4) connecting the wells to a single header assembly rather than multiple headers.

- Integrating a geothermal energy system into the open-loop water treatment system, through installation of a heat pump relying on a single 1.5-ton geothermal heat exchange unit connected directly to the well head assembly.

- Using the U.S. Green Building Council's Leadership in Energy and Environmental Design (LEED) program as a platform to evaluate and acquire energy-efficient and environmentally friendly products to be used in treatment plant construction.

- Investigating local sources of equipment that could be repurposed for the groundwater treatment systems, to maximize material reuse and reduce the volume of material disposed of at local landfills (while reducing project costs).

- Designing cleanup in ways that minimize negative effects on surrounding neighborhoods and accommodate community options for future reuse of the Lawrence Aviation Industries (LAI) site, particularly at the offsite property located within the village. One significant requirement for the offsite groundwater treatment building involved using an exterior design that fit the community's architectural style.

Results:

Renewable Energy and Energy/Material Efficiency in Treatment Process

- Using onsite geothermal energy to condition interior air of both treatment plants. At each building, the extracted groundwater is immediately routed to the heat exchanger from which heated or cooled air (during winter or summer seasons, respectively) is transferred to the building ductwork at an average rate of 600 standard cubic feet per minute. Temperatures of the extracted groundwater average 56°F.

- Using reactivated instead of virgin carbon in the air stripping systems used to treat groundwater after its passage through the heat exchangers. Each system employs a filtration vessel with capacity to hold 3,000 pounds of granular carbon.

- Optimizing treatment efficiencies through use of bag filters to remove solid material from water exiting the air stripping systems, which reduces potential plugging in effluent discharge pipes and limits potential damage to components of the treatment system.

- Reusing equipment that was reconditioned and refabricated to meet most treatment process needs at the onsite plant. An air stripper no longer needed by the U.S. Environmental Protection Agency (EPA) for ex situ groundwater treatment at a local site contaminated by past drycleaning activity was relocated at the LAI site. Additionally, EPA decommissioning of an un-needed groundwater pump-and-treat system at another site enabled reuse of two aqueous phase carbon vessels, a vapor phase carbon vessel, bag filters, a blower device, piping, valves, connectors, pumps, electrical wiring and interior light fixtures at the LAI site.

- Avoiding 6,000-7,000 kilowatt hours of grid-supplied electricity at each plant every year by allowing the ground below and around the treatment building to serve as the structure's heat source in winter and heat sink in summer.

- Saving $1,300-1,700 in annual operation and maintenance costs for each plant every year through avoided electricity purchasing for interior air heating or cooling.

- Offsetting an estimated 4.1 to 4.8 metric tons of carbon dioxide (equivalent) associated with each plant annually through use of renewable, geothermal energy.

- Treating an average of 53 million gallons of groundwater each year, for a cumulative total of 510 million gallons since start-up of both plants in 2011. In 2013, the average annual treatment rate rose from 34 million gallons to 70 million gallons due to adjustments in the capacity of activated granulated carbon.

Green Purchasing for Treatment Plant Construction

- Acquired most lumber from a Certified Green Dealer™ lumberyard and maximized purchases of wood certified under the Sustainable Forestry Initiative® or Program for Endorsement of Forest Certification.

- Chose double-hung, argon-filled windows with an energy performance U-factor of 0.30.

- Selected a "cool" roof made of highly reflective metal, with a solar reflectance index (SRI) value of 29, while meeting Village of Port Jefferson architectural requirements.

- Used low-maintenance, insect- and weather-resistant composite siding made of sustainable materials with low toxicity, such as wood pulp, cement and sand.

- Insulated exterior walls with spray foam made of renewable resources (soybeans) and through processes involving no formaldehyde, petroleum, asbestos, fiberglass or VOCs. The insulation also reduces noise impacts on nearby residential properties; sounds emanating from the treatment plants are typically below 50 decibels.

- Equipped the treatment buildings with tank-less water heaters that provide heated water on demand, which avoids the need for storage tanks and associated heat loss.

- Chose treatment-area flooring consisting of polished and sealed concrete, and covered floors of common areas with panels of rapidly renewable cork and an underlayment made of post-consumer recycled granulated rubber from tires.

- Selected light-reflective ceiling tiles comprising 45% rapidly renewable resources and 23% recycled content.

- Used remnant framing lumber instead of virgin wood to construct interior cabinetry, functioning hurricane shutters and architecturally aesthetic carriage doors.

Site-Wide Resource Efficiencies

- Recharging the underlying aquifer by returning treated water from the onsite plant to the aquifer, through a network of five 258-foot injection wells approximately 1,000 feet upgradient from the extraction wells.

- Discharging treated water from the downgradient plant to local surface waters (an existing pond and its adjoining creek) rather than the sewer system, at a point approximately 20 feet from the extraction wells.

- Reduced electricity usage by equipping the offsite extraction pumps with variable speed drives (VSDs), which allow the pumps to operate at lower speeds while still meeting flow demands. When compared to alternate use of single-speed drives, VSDs also cause less equipment stress, thereby reducing maintenance needs (and associated costs) and potentially extending equipment life.

- Substituted asphalt pavement in parking and access areas with a pervious pavement system that allows grass to grow through the pavement, allows rainwater to infiltrate soil below the pavement, and avoids the temperature extremes encountered on asphalt surfaces.

- Transferred and stockpiled 240 tons of soil that was excavated during pervious pavement installation to a nearby municipal property for as-needed use by the Port Jefferson Highway Department. Prior to transfer, analytical tests were conducted on the soil to assure no residual contamination.

- Landscaped the site after building construction by removing invasive non-native vegetation, installing biodegradable jute matting to initially control soil erosion and establish plant roots, installing native low-maintenance plant species with approval from state and local organizations, and mulching areas with chipped wood from selected trees requiring removal prior to construction.

- Maximized use of locally based resources (within 15 miles of the site), such as subcontracted workers and equipment rental companies, and use of locally made products.

Property End Use: Potential community recreation, pending Superfund close-out.

Point of Contact: Keith Glenn, U.S. Environmental Protection Agency, Region 2

Update: February 2016

More detail is available in EPA Region 2's site green sheet![]() for Lawrence Aviation Industries Site, Old Mill Pond Area, Port Jefferson, New York

for Lawrence Aviation Industries Site, Old Mill Pond Area, Port Jefferson, New York